36

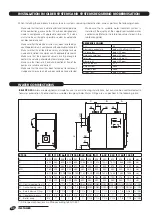

TECHNICAL ASSISTANCE SERVICE

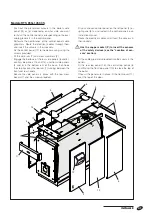

Regular maintenance is a legal requirement. It is also

essential for the safety, efficiency and durability of the

boiler. Proper maintenance keeps consumption and

emissions down, and ensures that the boiler continues to

operate reliably over time.

Have your boiler serviced either by

r

’s Technical

Assistance Service or by a qualified heating engineer.

Analyse the combustion fumes before commencing any

maintenance. The results of fume analysis can give a

clear idea of what servicing or repairs are needed.

1

2

1

1

3

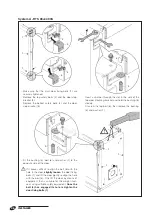

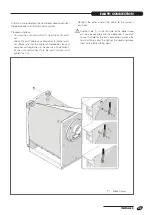

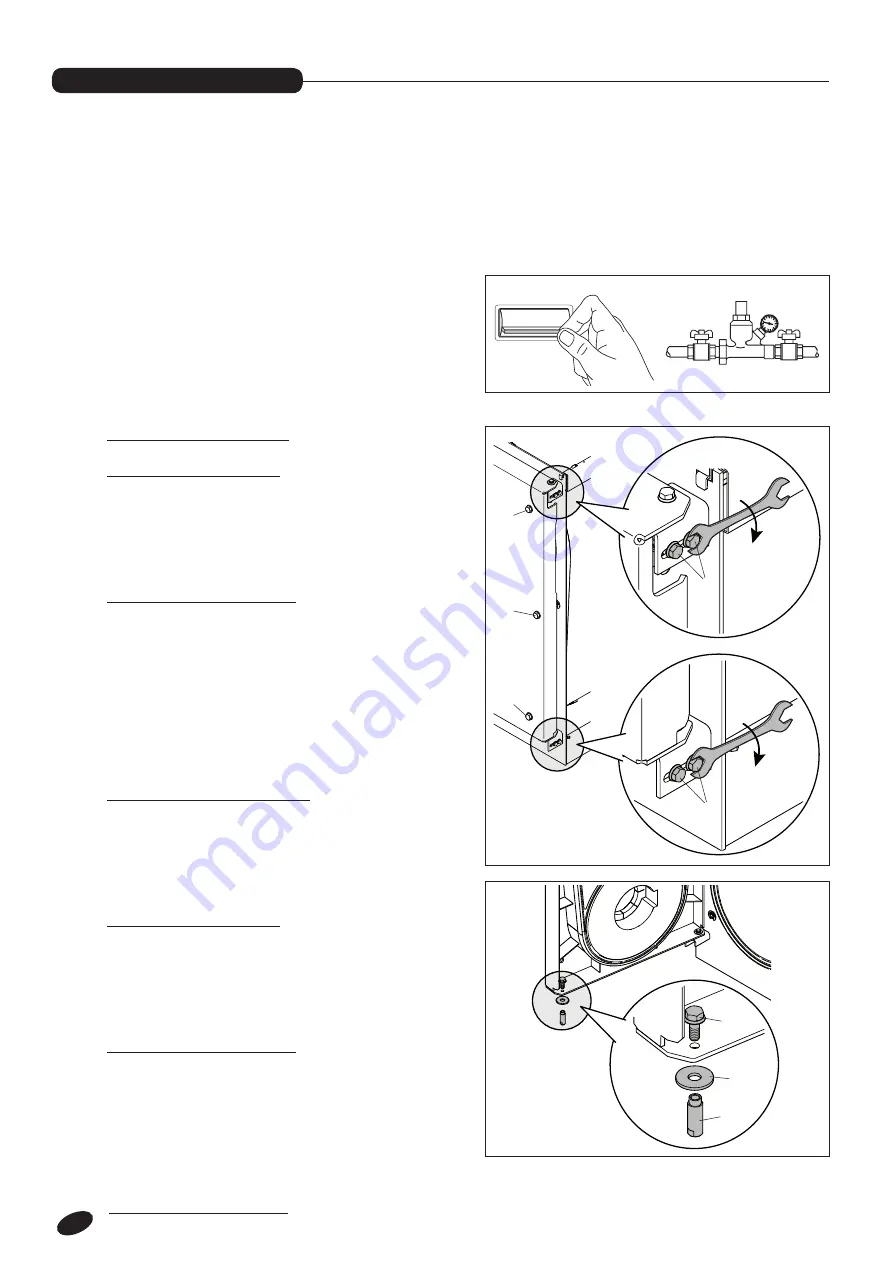

OPENING THE DOOR

System A - RTS 90÷349 3S:

- Make sure that the top safety bolts (2) and bottom safe-

ty bolts (3) on the hinged side of the boiler are tight.

- Completely unscrew the main fixing bolts (1) and open

the door. (These bolts are captive in the door and can-

not be removed.)

System B - RTS 448÷1450 3S:

- Completely unscrew the main fixing bolts (1) and open

the door. (These bolts are captive in the door and can-

not be removed.)

b

The first time you open the door, remove the

spare hinge assembly ‘B’ (bushing (10), bolt (9),

and washer (11)) opposite the hinged side of the

door.

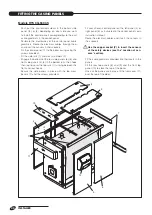

ADJUSTING THE DOOR

Make quite sure that the door presses uniformly all

around the double seal to prevent dangerous fumes

escaping into the air from the pressurised furnace.

Proceed as follows to adjust the door seals:

System A - RTS 90÷349 3S:

- Push the door shut and tighten the main fixing bolts (1)

until the seals start to compress.

- Loosen the safety bolts (2 and 3) then fully tighten the

main door fixing bolts (1).

- Re-tighten the safety bolts (2 and 3).

System B - RTS 448÷1450 3S:

- Push the door shut and tighten the main fixing bolts (1)

until the seals start to compress.

b

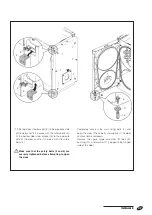

Make sure that the door is properly adjusted after

every maintenance operation.

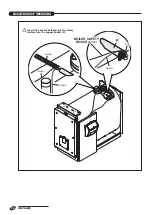

- Turn the system’s main power switch OFF

- Close the fuel shut-off cocks.

b

Make sure that the door is properly adjusted after

every maintenance operation.

ON

OFF

2

3

4

5

9

11

10

B

1

1

1

1

1

1

Maintenance

MAINTENANCE