INSTALLER

36

b

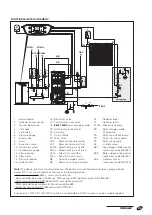

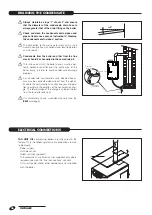

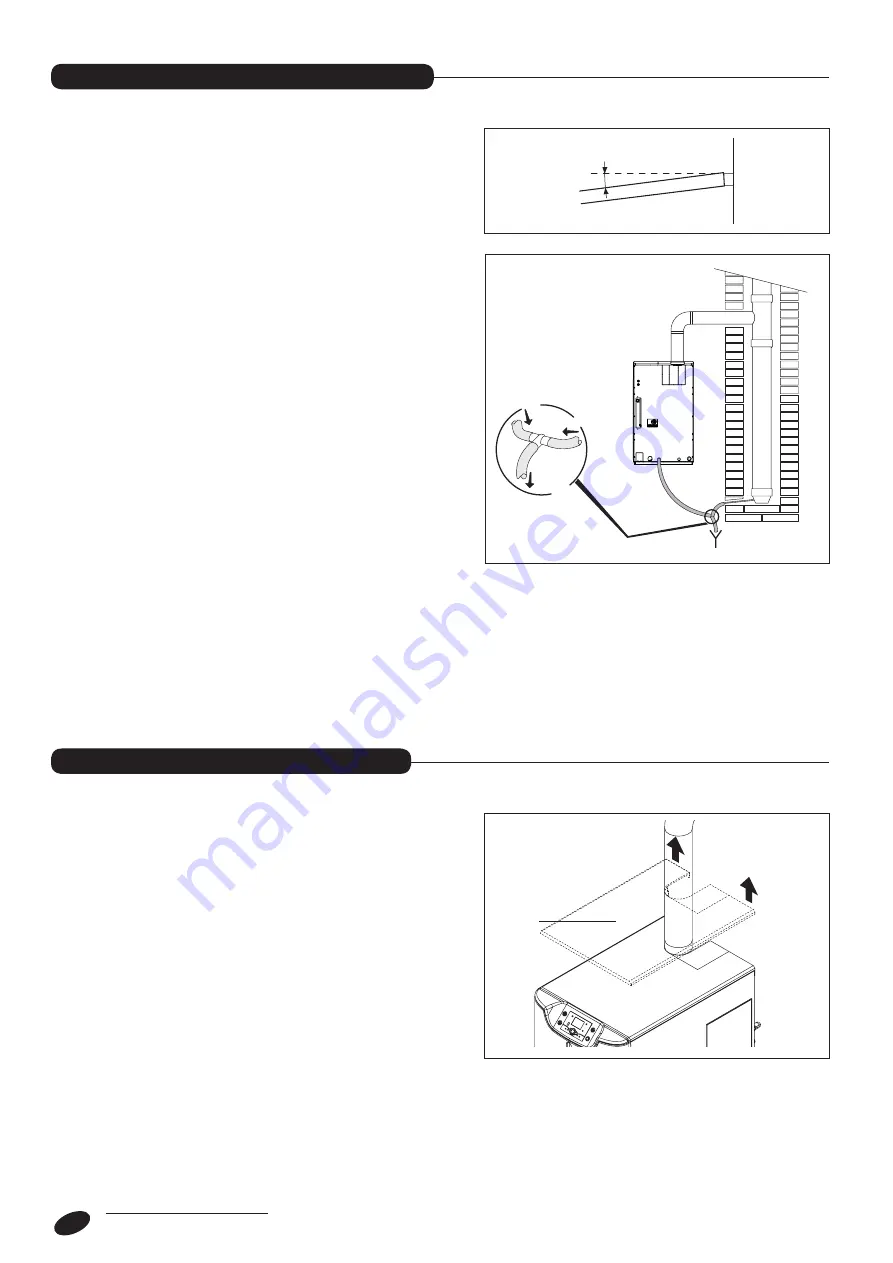

Always maintain a slope “i” of over 3° and ensure

that the diameter of the condensate drain hose is

always greater that of the drain fitting on the boiler .

b

Check and clean the condensate drain siphon and

pipes at least once a year, as instructed in “Cleaning

the condensate drain siphon” section.

b

The connection to the waste water drain pit must be

made in compliance with national and local legislation

and standards.

b

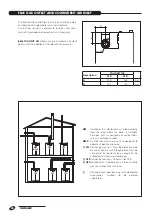

Condensate from the boiler and that from the flue

stack should be channelled to the same drain pit .

b

The surface on which the boiler stands must be per-

fectly horizontal and flat over the entire area of the

boiler frame in order to avoid condensate drainage

problems.

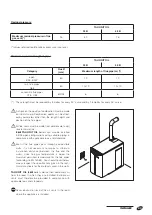

b

Any condensate neutralisation units deemed neces-

sary may be connected downstream from the siphon.

Evaluate the neutralisation unit after one year of opera-

tion to estimate the duration of the neutralisation char-

ge. The total duration of the charge can be estimated

from the level after one year.

b

It is mandatory to use a condensate trap (see the

r

catalogue).

i

i

≥

3°

BOILER

Drain

Condensate from stack

Condensate

from boiler

To drain or

neutralisation

unit if installed

Flue

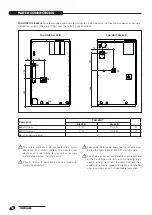

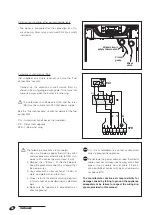

TAU UNIT OIL

condensing boilers are fully wired in the

factory. Only the following electrical connections remain

to be made:

- Power supply

- Outside sensor

- Room unit (not supplied)

- The automatic shut-off device (not supplied; only where

required; see also the “Fuel connections” section)

- CH circuit pump and/or other components not supplied

with the boiler.

1

Draining the condensate

DRAINING THE CONDENSATE

Electrical connections

ELECTRICAL CONNECTIONS