GENERAL

6

These

TAU UNIT OIL

boilers are high efficiency, fuel oil

burning condensing boilers for heating. They can also

produce domestic hot water if an optional remote storage

cylinder is installed.

These boilers may be used as type “C” boilers if the com-

burent air inlet is extended to draw in air from outside the

room where they are installed.

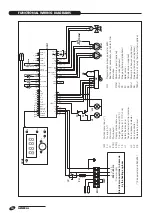

Used in conjunction with suitable optional water circuit

and electrical kits, these boilers can be used to serve up

to two central heating circuits (zones).

The most important technical features of these boilers are:

- The combustion chamber and heat exchange system

are specially designed and shaped to achieve the best

possible volume ratio.

- The primary heat exchanger features vitrified steel pi-

pes and wave turbulators to recover and transfer a large

proportion of the thermal energy carried by the combu-

stion fumes.

- The secondary heat exchanger is made from AISI 904L

stainless steel and recovers latent heat from the fumes,

boosting efficiency to up to 100.7% (50°C-30°C).

The exclusively designed heat exchange unit and se-

condary exchanger are insulated by ultra-efficient high

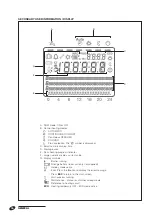

density glass wool. The controls and safety devices in the

electronic control panel conform to all applicable techni-

cal and safety standards.

A highly flexible controller permits an additional zone to

be served directly and also permits integration with

r

solar heating systems without additional controllers.

TAU UNIT OIL

r

boilers are equipped with the following safety devices:

-

A safety valve

that opens if pressure in the heating

circuit rises above the 3 bar threshold.

-

A safety thermostat

that forces the boiler to perform

a safety shutdown if temperature exceeds the safety

threshold (110°C).

-

A flue gas thermostat

in the bottom of the secondary

heat exchanger that triggers a fault condition if flue gas

temperature exceeds 90°C.

-

Burner safety device:

The fuel oil burner is equipped

with an electronic device to monitor correct implemen-

tation of the selected program. In the event of a fault,

this device sends the control panel a burner lockout

signal and displays a precise diagnostic signal.

b

The intervention of a safety device indicates a

potentially dangerous malfunction in the system,

and means that you must contact

r

’s Technical

Assistance Service immediately.

You may attempt to restart the boiler after a short delay

(see Preparing for initial start-up).

a

Never start the boiler up even for a short period if

the safety devices are not functioning correctly or

have been tampered with.

b

Safety devices must only be replaced by

r

’s

Technical Assistance Service using original spare

parts. Refer to the spare parts catalogue supplied

with the boiler.

Always check that the boiler is functioning correctly after

any repairs.

Safety devices

SAFETY DEVICES

Product description

PRODUCT DESCRIPTION