INSTALLER

34

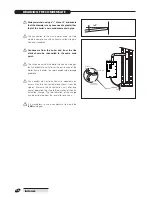

On models 26 B and 35 B:

- Open the water supply shut-off cocks and slowly fill the

central heating system until the pressure gauge reads

out a value of

1.5 bar

(cold).

On models 26 BK and 35 BK:

- Open the filling cock (1) and slowly fill the central heat-

ing system until the pressure gauge installed as part of

the installation reads out a value of

1,5 bar.

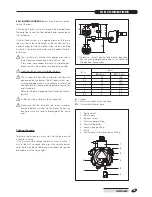

- Close the water supply shut-off cocks. On models 26 BK

and 35 BK, close the filling cock (1) too. Tighten down

the cap on the automatic vent valve (5).

- Close the non-return valve (4) on the CH flow pipe. On

models 26 BK and 35 BK, close the non-return valve (5)

too. See the figure to ascertain the correct position for

the dot on the screw.

FILLING THE STORAGE CYLINDER

(models 26 BK and 35 BK only)

- Make sure that storage cylinder drain cock (fitted dur-

ing installation) is closed.

- Open the DHW user taps.

- Open the DHW circuit shut-off cocks and slowly fill the

storage cylinder until clean, air-free water flows out from

the taps in a uniform manner.

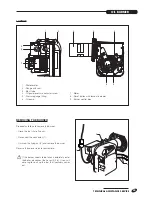

1

5

4

3

2

Non-return

valve OPEN

Non-return

valve OPEN

INSIEME CONDENS 26 BK and 35 BK

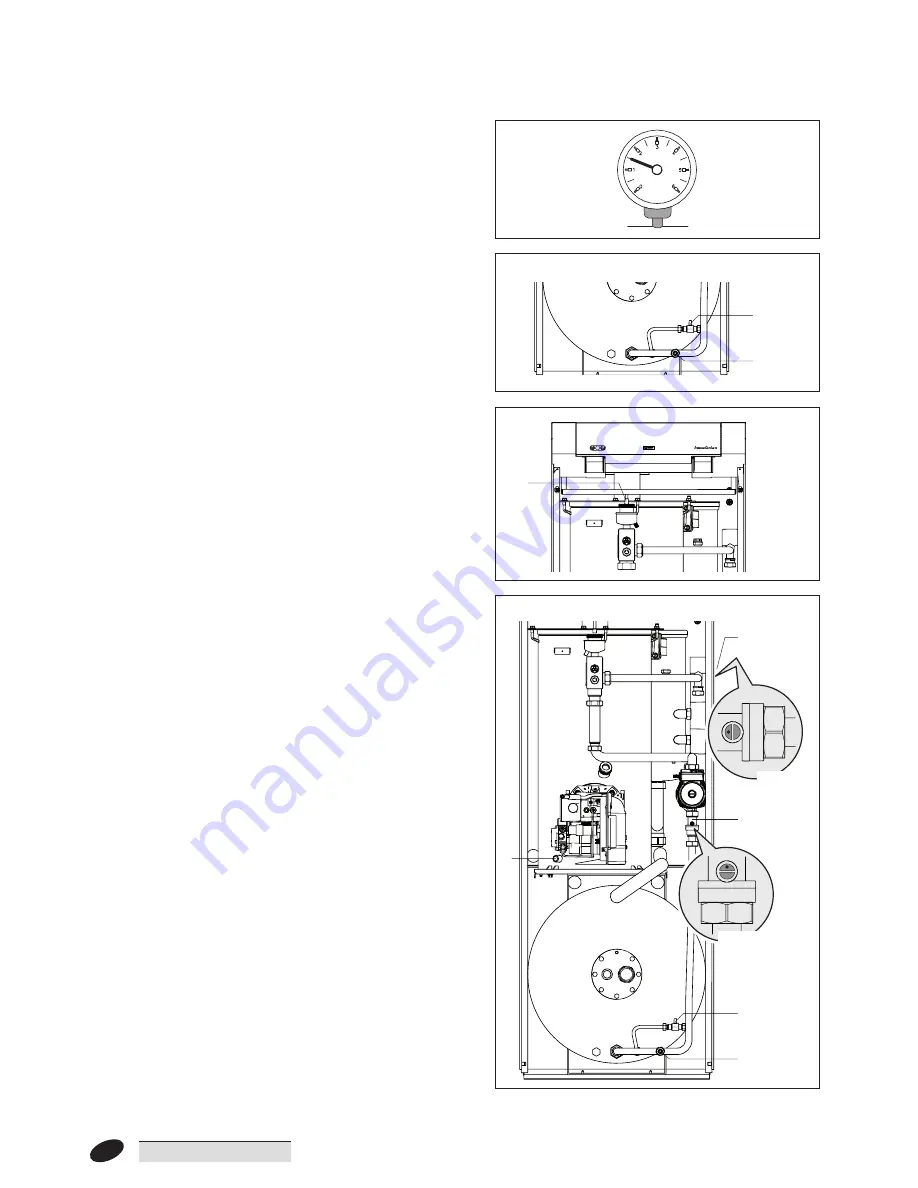

2

6

1

5

4

3

2

Non-return

valve in

CLOSED

(non-return)

position

Non-return

valve in

CLOSED

(non-return)

position

INSIEME CONDENS 26 BK and 35 BK