11

ENGLISH

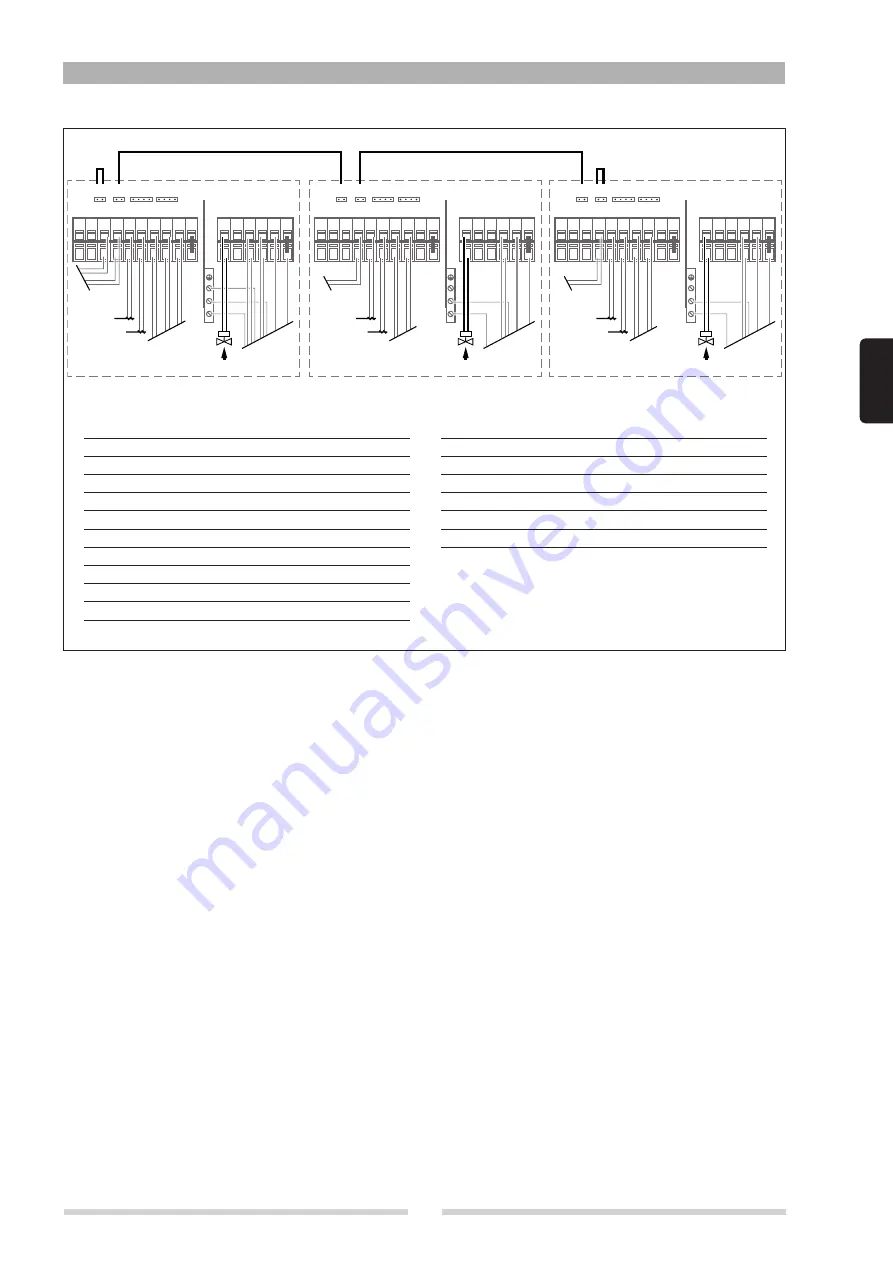

CAN CAN VFS2 VFS1

CAN CAN VFS2 VFS1

CAN CAN VFS2 VFS1

R3 R3I R2 R1 L N

-

V1 S5 S4 S3 S2 S1

V2

S6

+

R3 R3I R2 R1 L N

-

V1 S5 S4 S3 S2 S1

V2

S6

+

R3 R3I R2 R1 L N

-

V1 S5 S4 S3 S2 S1

V2

S6

+

S5

S4

CAVO CAN BUS

LATO SONDE E CONTROLLO

LATO

ALIMENTAZIONE

230 V

CAVO CAN BUS

AFS

S5

S4

LATO SONDE E CONTROLLO

LATO

ALIMENTAZIONE

230 V

AFS

S5

S4

LATO SONDE E CONTROLLO

LATO

ALIMENTAZIONE

230 V

AFS

Max. low voltage 12 VAC / DC

Terminal:

Connection for:

S1

Recirculation

S2

Cold water sensor

S3

Primary flow rate (optional)

S4

Storage cylinder top sensor

S5

V1

Primary pump PWM signal

V2

0-10V/PWM signal (optional)

S6

Primary return (optional)

-

Cold water draw-off sensor

VFS2

optional

Power terminals 230 VAC 50-60 Hz

Terminal:

Connection for:

L

Mains power, phase L

N

Mains power, N

R1

Primary circuit pump

R2

Relay 2 (recirculation option)

R3

Relay 3 (normally open)

R3I

Relay 3 (normally open)

The earth wire must be connected to the metallic PE

terminal!

ELECTRICAL CONNECTIONS

The cascade of ACS 40 E DHW mixers is controlled electronically by the control units. The various mixers in the cascade

are connected via a CAN bus cable between their control units.

- Unscrew the screw at the bottom of the front cover and open the control unit.

- Plug the CAN bus cable into the connector in the control unit (see terminal diagram).

- Fit terminating jumpers to the start and end connectors in the first and last DHW mixers in the cascade.

- Connect the various control units with the CAN bus cable provided.

- Connect the solenoid valve in the cold water inlet pipe to each DHW mixer to relay 3 in the power terminals of the mixer’s

control unit.

- Connect the recirculation pump to the first mixer in the cascade, connecting the power cable to relay 2 in the power

terminals and connecting the control cable to control terminal V2.

Procedure for recognising the CAN bus cable and activating the cascade function:

- Switch on the control unit.

- When the display lights up, press ESC key for 10 seconds.

CAN BUS CABLE

CAN BUS CABLE

SENSOR AND CONTROL TERMINALS

230 V

POWER

TERMINALS

230 V

POWER

TERMINALS

230 V

POWER

TERMINALS

SENSOR AND CONTROL TERMINALS

SENSOR AND CONTROL TERMINALS