10

1.9

Hydraulic system

Limescale and other chemical substances in the water can so-

lidify producing incrustations. To prevent this happening, equip

the system with a closed expansion tank. The water that en-

ters the closed expansion tank does not evaporate and is not

dispersed. In this way the level of water in the system is kept

constant and it will not be necessary to add fresh water. In ad-

dition, limescale and dust do not form and the system will have

a longer life.

− The water circulating in the system is not to be used for

washing or drinking.

− Do not take water from the system. If the water level is

low, top it up.

− To prevent damage due to limescale or chemical residues,

put water in the system with the following recommended

values: pH > 7.2 TH <25 °Fr. Check the water quality, and

if the quality of the water used does not meet the re-

quired requisites subject the water to suitable corrective

processes to obtain the required quality.

− To prevent the formation of limescale or sediments inside

the boiler or their passage from the boiler to the hydraulic

system, equip the system with suitable protections both

inside and on the outside.

− Connect the circulation pump to the boiler water outlet.

The power of the pump should be suitable for the boiler.

− Provide a 4-way mixing valve or a pump on the by-pass

section activated by a thermostatic control to raise the

temperature of the water in the return line.

− Provide a 3-way motorised valve connecting the supply

line and the return line of the heating system, to adjust

the flow rate of the water in the system according to the

desired performances.

− The amount of water in the system should be such that

there is always water in the boiler. Otherwise the boiler

could be subject to corrosion. If the boiler is not used in

winter, in order to prevent damage from freezing, use an

anti-freeze product, periodically measure the amount of

water in the boiler with a pressure gauge if it has a closed

expansion tank or with a water gauge if it has an open

expansion tank.

REFERENCE VALUES

pH

less than 7.2

Electrical conductivity

less than 200 μs/cm (25°C)

Chloride ions

less than 50 ppm

Sulphuric acid ions

less than 50 ppm

Total iron

less than 0.3 ppm

M alkalinity

less than 50 ppm

Total hardness

less than 25° F

Sulphur ions

none

Ammonia ions

none

Silicon ions

less than 30 ppm

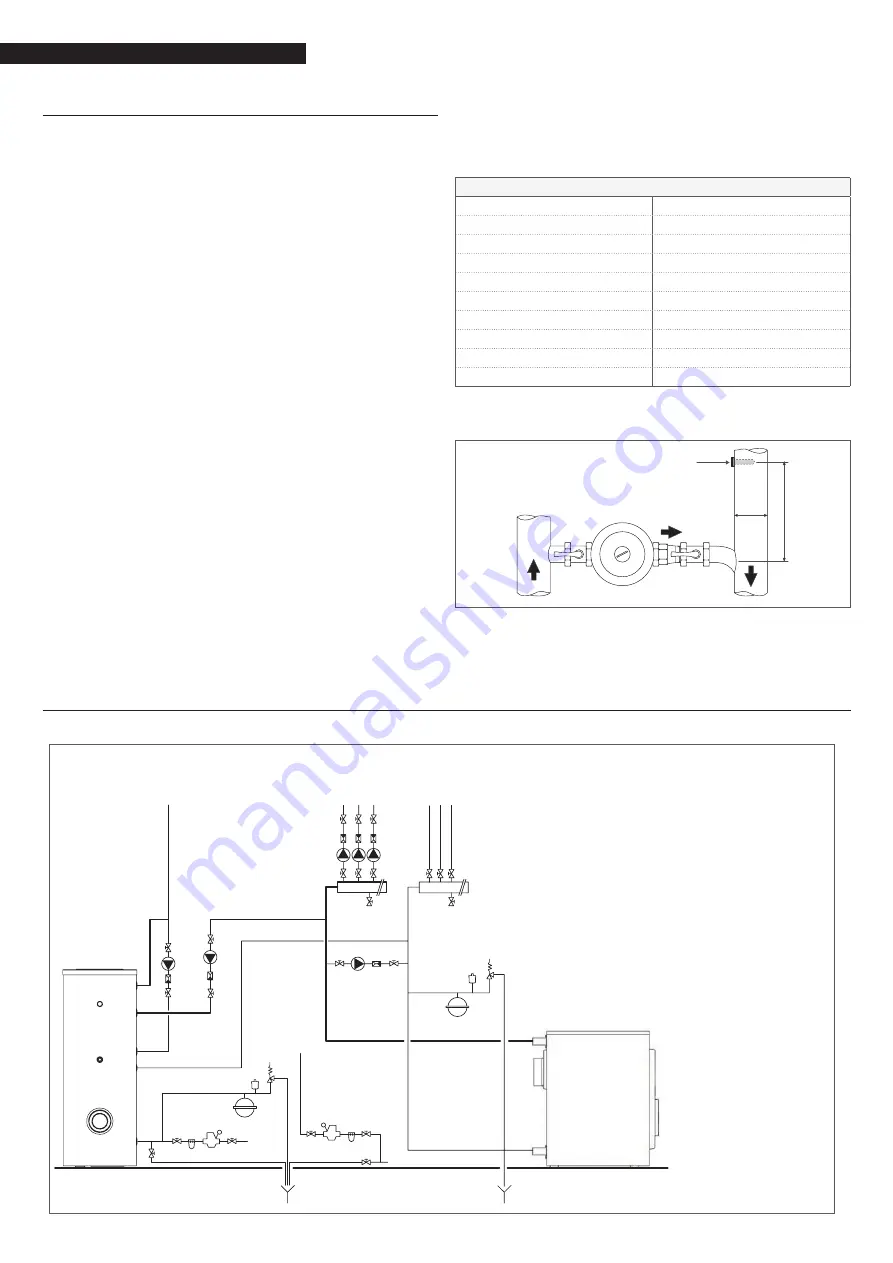

The Thermostat (1) should be installed at a distance of 3-5 diam-

eters from the connection point to the return line.

D

1

3÷5

D

3

2

2

3

3

3

4

5

3

8

10 15

10

13

14

12

1

EAF

EAF

15

6

3

3

3

3

11

6 7

17 5

3

3

3

5

3

4

3

5

3

4

SYSTEM

OUTLET

SYSTEM

RETURN

LINE

DOMESTIC

WATER

UTILITIES

DISCHARGES

DISCHARGES

1

Boiler

2 System manifolds

3 Shut-off valves

4 System pumps

5 Non-return valves

6 Automatic vent valve

7 Boiler safety valve

8 Boiler discharge tap

9 Storage heater safety valve

10 Charging the system

11 System expansion tank

12 Storage heater

13 Storage heater discharge tap

14 Domestic hot water expansion

tank

15 Softener filter

16 Pressure reducer

17 Condensation pump

1.10

Schematic diagram - system for heating and domestic hot water production