13

water should be no greater than 20 °C. The boiler should not be

started or run with water volumes lower than those indicated in

the following table.

Type of

boiler

Output

∆

t = 15 K (*)

∆

t = 20 K (*)

kCal/h

kW

Water

flow

rate

Water

resist-

ance

Water

flow

rate

Water

resist-

ance

m

3

/h

mbar

m

3

/h

mbar

RTT 76

65,000

75.6

4.333

17.2

3.250

7.6

RTT 93

80,000

93.0

5.333

18.0

4.000

10.0

RTT 110

95,000

110.5

6.333

23.5

4.750

15.6

RTT 128 110,000

127.9

7.333

29.0

5.500

19.0

RTT 145 125,000 145.3

8.333

34.0

6.250

22.3

(*)

∆

t = temperature difference

NOTA:

The RTT boiler has been designed only for heating systems

with forced circulation of hot water.

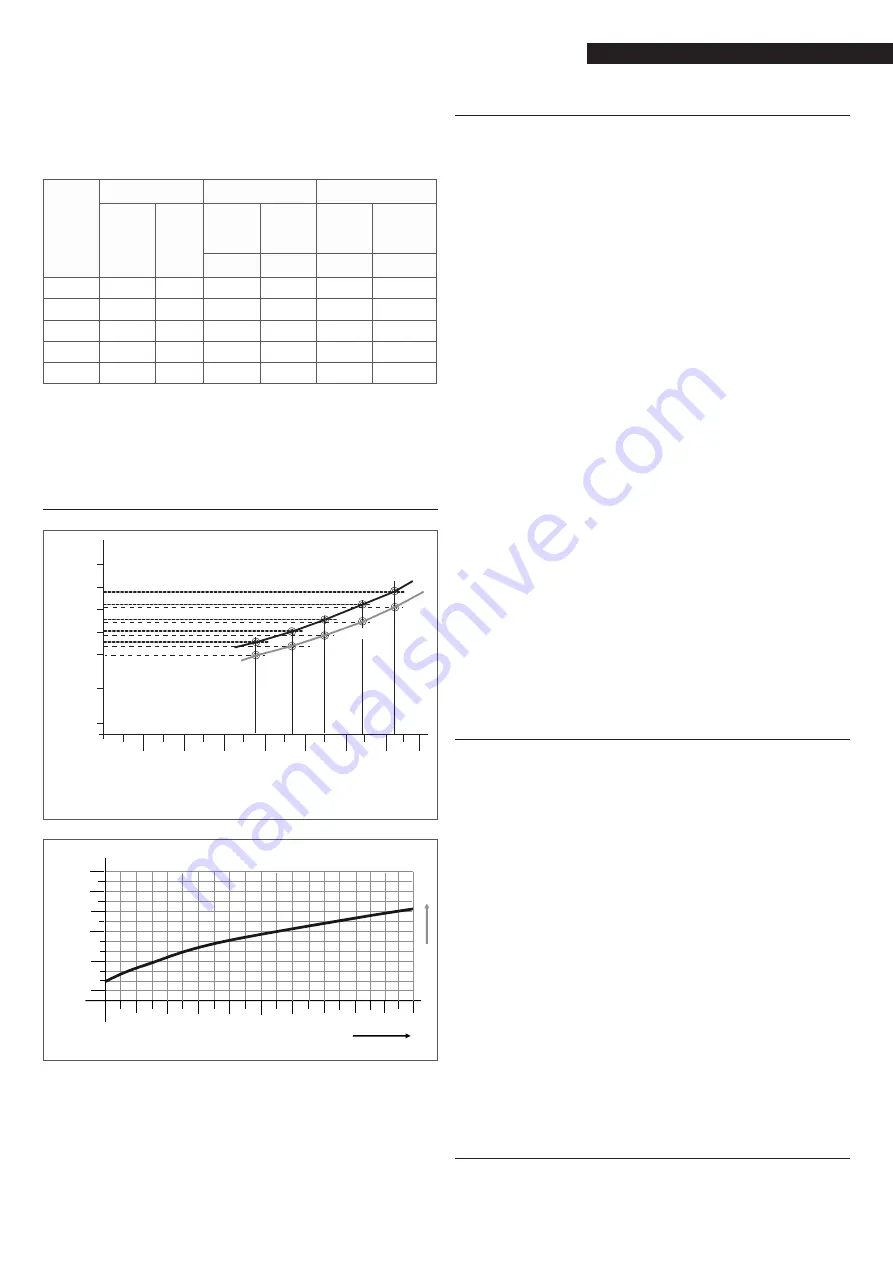

1.16

Gas side resistance and output temperature

of combustion gases

0,20

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

0,80

1,40

1,80

2,20

2,60

3,00

Full load

Part Load

Heat output (kW)

Gas side resistance (mbar

)

100

130

180

200

220

160

10

20

30

40

50

60

70

80

90

100

Exit flue gas temperature (°C)

Load (%)

1.17

User instructions

Heating system

In the heating system, the difference between the direct supply

temperature and the water return temperature should not ex-

ceed 20°C. The temperature of the return water should higher

than 50°C. Use the boiler's protection pump to raise the tem-

perature of the return line water. Regularly measure the system's

water level and add water if it is too low. Before adding water to

the system, stop the system and wait for the water temperature

to reach 40°. Check for and resolve any problems due to leaks in

the boiler or in the system.

The hydraulic system should be carried out by qualified person-

nel to meet European standards.

For the system use material complying with European stand-

ards.

Connections to the electrical system and fuel delivery system

All the electrical connections should be carried out in compli-

ance with European standards, using only material approved by

European regulations, by qualified professionals. For the burn-

er, the control panel, Ecopanel etc., read the instructions and

warnings carefully in the instruction manuals supplied by the

manufacturer or distributors. Do not switch on the burner un-

til the circulation has started inside the boiler. If the circulation

pump or the protection pump are faulty, switch off the burner.

The system should work in a coordinated manner.

The circulation pump should always be operating when the

burner is running. Choose a protection pump that is adequate

for the boiler output. Connect the pump to the collectors, to the

valve and to the thermostat correctly. In this way the system

can switch off once the pre-set temperature has been reached.

When faced with any fault (contactor, temperature swings,

interruption of current, other faults), or when the pumps are

stopped (protection pumps, etc.) the burner should switch itself

off. The system should do this automatically.

Carry out the electrical wiring taking into account all the

above-mentioned information.

1.18

Conveyance and discharge of the boiler

water

Discharge of the boiler water

9

Switch off the boiler before emptying the boiler and let it

cool.

To empty the boiler, open all the valves of the circuit and the

radiators. All the system water should be discharged by drain-

ing the boiler, when the latter is in the lower part of the system

itself. If a part of the heating system is below the boiler room,

the process for draining the water can be carried out at a point

situated in the lower part of the system.

Supplying the boiler with water

To fill the boiler with water use the tap upstream of the boil-

er, during the boiler charging operations all the valves of the

hydraulic piping and radiators should be open. To prevent air

infiltration, carry out this operation slowly opening the plug at

the top. When water comes out of this plug it means the process

has finished. Bleed the air from all the radiators.

9

Do not fill the boiler with water when the boiler is hot. This

could damage the elements

9

The quality of the water should correspond to that indicated

in "1.9 Hydraulic system" a pagina 10

1.19

Instructions for disposing of the product

Cast iron boilers have a long life due to the particular character-

istics of the construction materials used. The service life of these

appliances, which is declared in the accompanying legal doc-