6

1.3

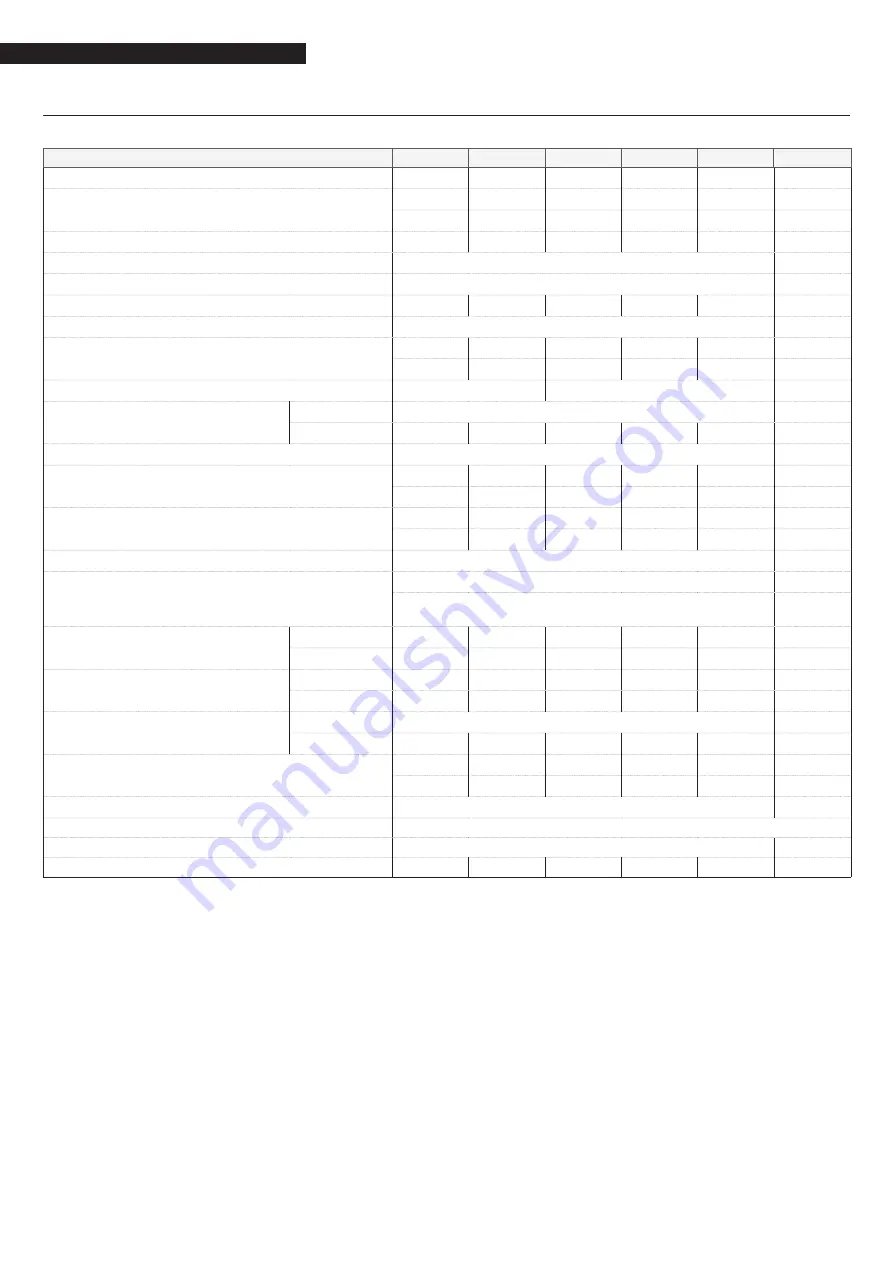

Technical data

RTT CAST IRON BOILER

RTT 76

RTT 93

RTT 110

RTT 128

RTT 145

UM

Number of sections

5

6

7

8

9

pieces

Nominal heat output

76

93

110

128

145

kW

65,000

80,000

95,000

110,000

125,000

kCal/h

Nominal heat input

82

101

120

138

157

kW

Maximum operating temperature

90

°C

Temperature adjustment range

30-90

°C

Gas side resistor

1.40-1.65

1.57-1.82

1.75-2.05

2.00-2.30 2.25-2.55

mbar

Maximum operating pressure

6

bar

Boiler water capacity

55

65

75

85

95

litres

0.055

0.065

0.075

0.085

0.095

m

2

Diameter flue pipe fitting

150

180

mm

Combustion chamber dimensions

width X length

336

mm

L

550

670

790

910

1,030

mm

Water input-output coupling

G 2

DN (*)

Boiler gas volume

64.1

78.36

92.62

106.88

121.14

dm

3

(lt.)

0.064

0.078

0.093

0.107

0.121

m

2

Combustion chamber gas volume

45.94

56.16

66.38

76.6

86.82

dm

3

(lt.)

0.046

0.056

0.066

0.077

0.087

m

2

Safety limit thermostat

110

°C

Type of fuel

I

2

H

gas

Extra light Fuel Oil

comb.

liquid

Flue gases output temperature

full load

184-187

179-185

175-182

170-177

169-174

°C

partial load

165-172

164-170

162-168

160-165

155-160

°C

Mass flow of the flue gases

full load

127

156

185

214

243

kg/h

partial load

76

93

111

129

146

kg/h

Boiler dimensions

Width X length

550 x 820

mm

L

800

922

1,044

1,166

1,288

mm

Heat loss in stand-by

0.32

0.29

0.27

0.23

0.21

%

2,246

2,506

2,770

2,732

2,835

kCal/h

Diameter burner hole

110

mm

Type of burner

With short head

Flue effect

5

Pa

Boiler net weight

285

330

377

425

470

Kg