15

20197230

GB

Hydraulic systems

6.3

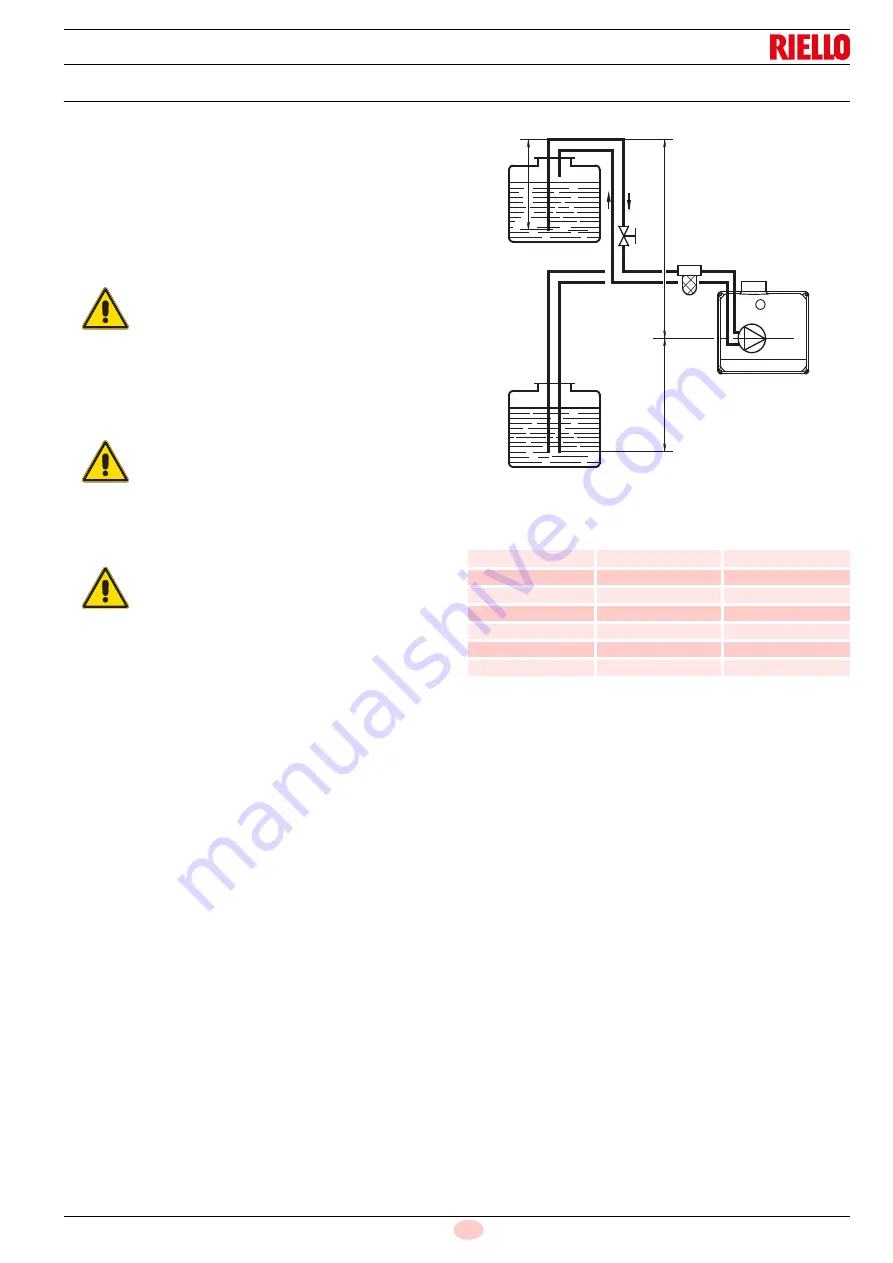

Two-pipe system

The two-pipe vacuum systems (Fig. 12) have a negative fuel

pressure (depression) at the burner input.

Usually the tank is lower than the burner.

The return line should terminate in the oil tank at the same level

as the suction line; in this case a non-return valve is not required.

Should however the return line arrives over the fuel level, the

non-return valve is indispensable.

This solution however is less safe than previous one, due to the

possibility of leakage of the valve.

6.3.1

Priming pump

On the system in Fig. 12 switch on the burner and wait for the

priming. Should lockout occur prior to the arrival of the fuel, await

at least 20 seconds before repeating the operation.

Tab. H

H

difference of level

L

maximum length of the suction line

I.D.

internal diameter of the oil pipes

NOTE:

Tab. H shows the maximum approximate lengths for the supply

line, depending on the difference in level, length, and the diame-

ter of the fuel conduit.

CAUTION

You are advised to use additional filters on the fuel

supply line.

The Manufacturer recommends the use of a good

quality fuel filter on the tank (Fig. 12), and a sec-

ondary filter (60

for light oil) to protect the burner

pump and nozzle from contamination.

WARNING

Before starting the burner make sure that the re-

turn pipe-line is not clogged: any obstruction

would cause the pump seals to break.

WARNING

The pump vacuum should not exceed a maximum

of 0.4 bar (30cm Hg).

Beyond this limit gas is released from the oil.

H

metres

L metres

I.D. (8 mm)

I.D. (10 mm)

0

35

100

0.5

30

100

1

25

100

1.5

20

90

2

15

70

3

8

30

3.5

6

20

max.

4 m

H

H

D5308

Fig. 12

Summary of Contents for 3749251

Page 2: ...Original instructions...