2044

8

GB

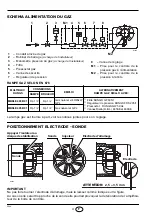

COMBUSTION ADJUSTMENT

In conformity with Efficiency Directive 92/42/EEC the application of the burner on the boiler,

adjustment and testing must be carried out observing the instruction manual of the boiler, includ-

ing verification of the CO and CO

2

concentration in the flue gases, their temperatures and the

average temperature of the water in the boiler.

It is advisable to set the burner according to the type of gas used and following the indications of the

table:

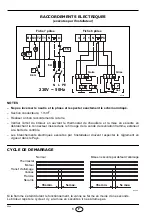

IONIZATION CURRENT

The minimum current required by the control box is 5

m

A.

The burner would normally have a higher current value than this, but if a check is required, open

the connector fitted in the red probe lead and insert a microammeter as shown.

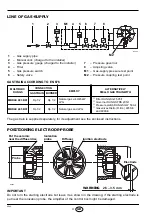

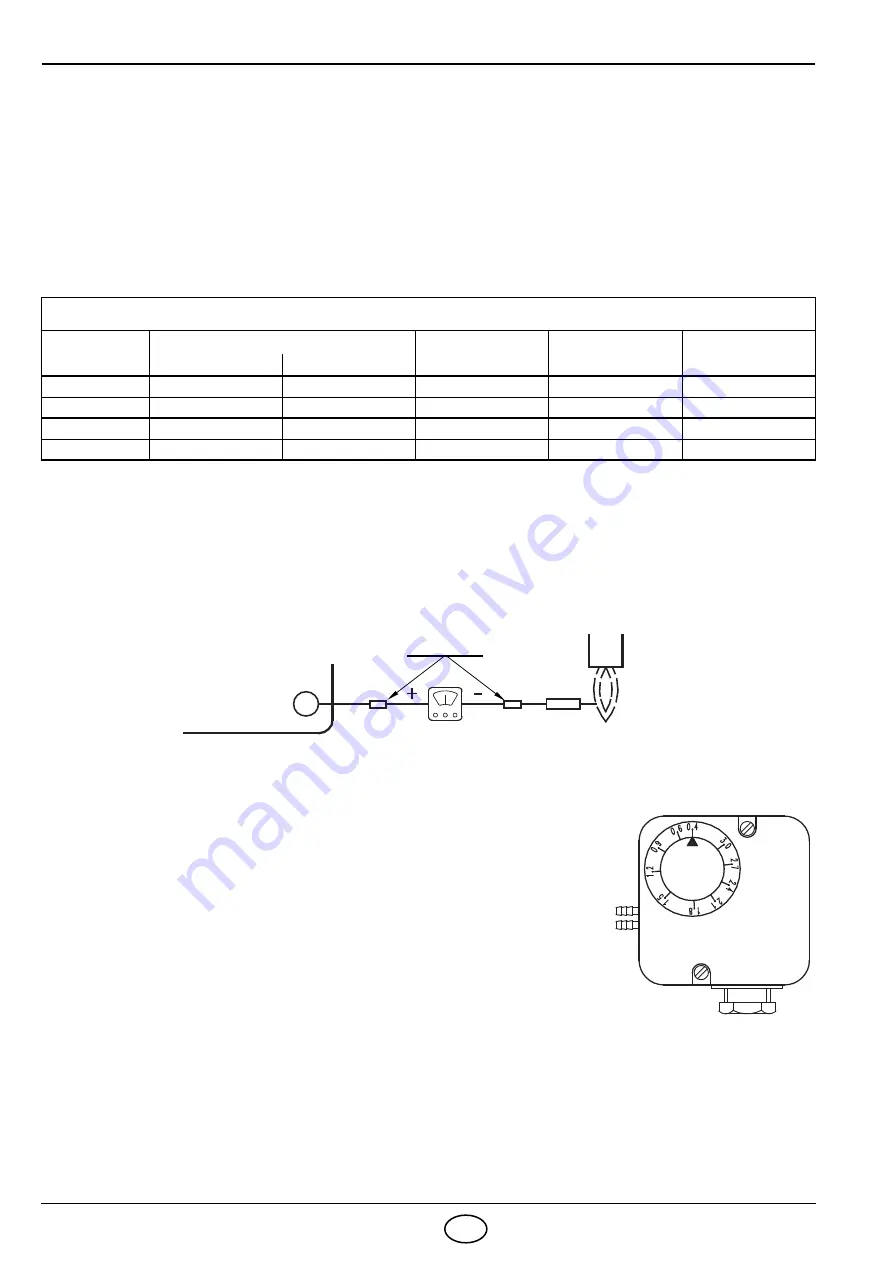

AIR PRESSURE SWITCH

The air pressure switch is set after all other adjustments have

been made. Begin with the switch at the lowest setting.

With the burner working at the minimum output, adjust the dial

clockwise, increasing its value until the burner shuts down. Now

reduce the value by one set point, turning the dial anti-clockwise.

Check for reliable burner operation, if the burner shuts down, re-

duce the value by a half set point.

Attention:

To comply with the standard, the air pressure switch must operate when the CO value exceeds 1%

(10,000 ppm).

To check this, insert a combustion analyser in the flue, slowly reduce the burner air setting and

verify that the burner shuts down by the action of the air pressure switch before the CO value

exceeds 1%.

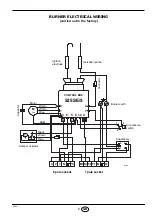

EN 676

Excess of air at maximum:

l

£

1.2

–

Excess of air at minimum:

l

£

1.3

GAS

Setting CO

2

%

CO

2 max

0 % O

2

CO

mg/kWh

NO

x

mg/kWh

l

= 1,2

l

= 1,3

G 20

9.7

9.0

11.7

£

100

£

170

G 25

9.5

8.8

11.5

£

100

£

170

G 30

11.6

10.7

14.0

£

100

£

230

G 31

11.4

10.5

13.7

£

100

£

230

Ionization probe

Connector

2

Control box

terminal block

D5006

D5049