2737

1

GB

INDEX

1.

BURNER DESCRIPTION

Gas burner with one stage working.

1.1

BURNER EQUIPMENT

Insulating gasket . . . . . . . . . . . . . No. 1

Screws and nuts for flange to be fixed to boiler . . No. 4

Cable grommet . . . . . . . . . . . . . . No. 1

Screws for fixing the cover . . . . . . . . . . . . . . . . . . No. 3

Hinge. . . . . . . . . . . . . . . . . . . . . . No. 1

1.

BURNER DESCRIPTION . . . . . . . . . . .

1

1.1

Burner equipment . . . . . . . . . . . . . . . . .

1

2.

TECHNICAL DATA . . . . . . . . . . . . . . . .

2

2.1

Technical data. . . . . . . . . . . . . . . . . . . .

2

2.2

Overall dimensions . . . . . . . . . . . . . . . .

2

2.3

Working field . . . . . . . . . . . . . . . . . . . . .

2

3.

INSTALLATION . . . . . . . . . . . . . . . . . .

3

3.1

Boiler fixing . . . . . . . . . . . . . . . . . . . . . .

3

3.2

Probe-electrode positioning . . . . . . . . . .

4

3.3

Gas feeding line . . . . . . . . . . . . . . . . . .

4

3.4

Electrical wiring . . . . . . . . . . . . . . . . . . .

5

3.5

Fixing the electrical wiring . . . . . . . . . . .

6

4.

WORKING . . . . . . . . . . . . . . . . . . . . . .

6

4.1

Combustion adjustment . . . . . . . . . . . . .

6

4.2

Combustion head setting. . . . . . . . . . . . .

6

4.3

Air damper setting . . . . . . . . . . . . . . . . . .

7

4.4

Combustion check. . . . . . . . . . . . . . . . . .

7

4.5

Air pressure switch . . . . . . . . . . . . . . . . .

7

4.6

Burner start-up cycle . . . . . . . . . . . . . . . .

8

4.7

Start-up cycle diagnostics . . . . . . . . . . . .

8

4.8

Resetting the control box and using

diagnostics . . . . . . . . . . . . . . . . . . . . . . .

9

5.

WARNINGS

to avoid burnout or bad combustion of the

burner . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

6.

MAINTENANCE . . . . . . . . . . . . . . . . . . . 10

7.

FAULTS / SOLUTIONS . . . . . . . . . . . . . 11

1

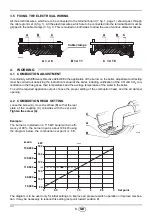

– Air-damper

2

– Screws for fixing the air-damper

3

– Cable clamps

4

– Cable grommet

5

– Screw for fixing the cover

6

– Air pressure switch

7

– Terminal board

8

– Control box

9

– Reset button with lock-out lamp

CE marking according to Gas Appliance Directive 90/396/EEC; PIN

0063AP6680

.

According to Directives: EMC 89/336/EEC, Low Voltage 73/23/EEC and Efficiency 92/42/EEC.

The burner meets protection level of IP X0D (IP 40), EN 60529.

The burner is approved for intermittent operation as per Directive EN 676.

Gas train according to EN 676.

NOTES:

– The cable grommet (4) supplied with the burner, must be fitted to the same side of the gas train.

– After having installed the burner verify the access to the fixing screws of the cover.

If necessary replace them with the fixing screws (5, fig. 1) supplied as equipment.

Fig. 1

2

1

2

D4190

5

4

3

9

8

7

6