2737

5

GB

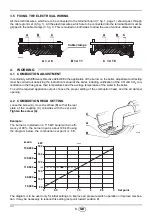

3.4

ELECTRICAL WIRING

ATTENTION:

Do not swap neutral and phase over, follow the diagram shown

carefully and carry out a good earth connection.

The section of the conductors must be at least 1mm².

(Unless requested

otherwise by local standards and legislation).

The electrical wiring carried out by the installer must be in compli-

ance with the rules in force in the country.

Verify that the burner stops by operating the boiler control thermo-

stats and that the burner locks out by separating the red ionisation

probe lead connector.

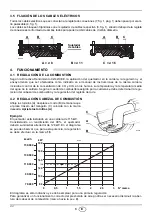

NOTES

The burners have been type-approved for intermittent operation. This

means they must stop at least once every 24 hours in order to allow the

electrical control box to check its efficiency on start-up. The boiler limit ther-

mostat (

TL

) normally ensures the burner halts. If this does not happen a

time switch halting the burner at least once every 24 hours must be applied

in series to limit thermostat (

TL

).

KEY TO LAY-OUT

PG

– Minimum gas pressure switch

S3

– Remote lock-out signal

(230V - 0.5 A max.)

T6A

– Fuse

TL

– Limit thermostat

TS

– Safety thermostat

V10

– Safety valve

V11

– Adjustment valve

Ionization probe

Ignition transformer

Electrode

Motor

Ca

pa

ci

to

r

Burner

230V

~

50Hz

Terminal board

Suppressor

Air pressure switch

Blue

White

Black

VERSION

FOR GAS LEAK CONTROL DEVICE

(DUNGS VPS 504)

Control box

RMG 88.620A2

D4258

Connector

earth

In the case of phase-phase feed,

a bridge must be fitted on the

control box terminal board be-

tween terminal 6 and the earth

terminal.

ATTENTION

TO BE DONE BY

THE INSTALLER

CARRIED-OUT

IN THE FACTORY