F10 - 10

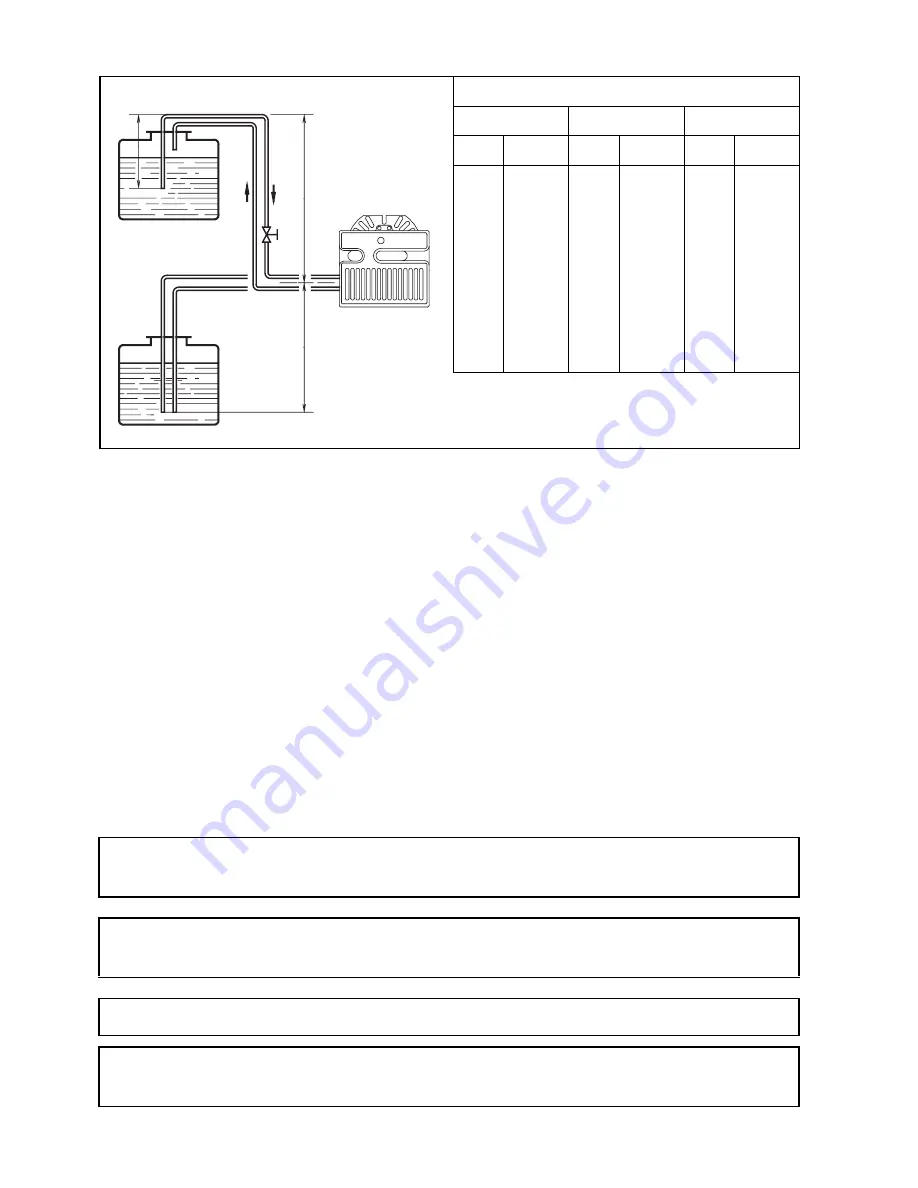

TWO LINE (LIFT SYSTEM)

A)

If a two line system is required, install the By-pass plug (4) provided. The by-pass

plug is installed in the return port (9) of the pump. A 2.5 mm hexagonal key provided

with the by pass plug is to be used to install the plug. DO NOT use an inch size

hexagonal key, damage to the by-pass plug may result. When operating on a two line

system, supply and return lines should be the same diameter and both

should extend

to the same depth inside the fuel tank.

Be sure there are no air leaks or blockages

in the piping system.

Any obstructions in the return line will cause failure of the pump shaft seal. Do not

exceed the pipe lengths indicated in the tables.

To install the by-pass plug:

1) Remove the return plug (9).

2) Install the by-pass plug (4) using the 2.5 mm hexagonal key.

B)

Attach the two PIPE CONNECTORS (5) to the pump SUPPLY and pump RETURN

PORTS (6 and 9). Attach the required piping to these two pipe connectors using the

NPT/METRIC ADAPTERS that are supplied with the burner.

WARNING: Pipe dope or Teflon tape are NOT to be used on any direct oil con-

nection to the fuel pump.

WARNING: The height “P” in Pipe Length charts on page 9 and 10 should not

exceed 13 feet (4 m).

WARNING: The vacuum should not exceed 11.44 inches of mercury.

IMPORTANT: An external, appropriately listed and certified oil filter must be

placed in the fuel line between the fuel tank and the burner pump.

2 LINE (LIFT) SYSTEM - PIPE LENGTHS

H

3/8” OD

1/2” OD

FT

M

FT

M

FT

M

0.0

0.0

115

35

330

100

1.5

0.5

100

30

330

100

3.0

1.0

80

25

330

100

5.0

1.5

65

20

295

90

6.5

2.0

50

15

230

70

9.5

3.0

25

8

100

30

11

3.5

20

6

65

20

NOTE:

Do not exceed pipe lengths

indicated in chart.

HP

H

D6008

Summary of Contents for 40 F10

Page 18: ...F10 16 SPARE PARTS ...