3222

10

GB

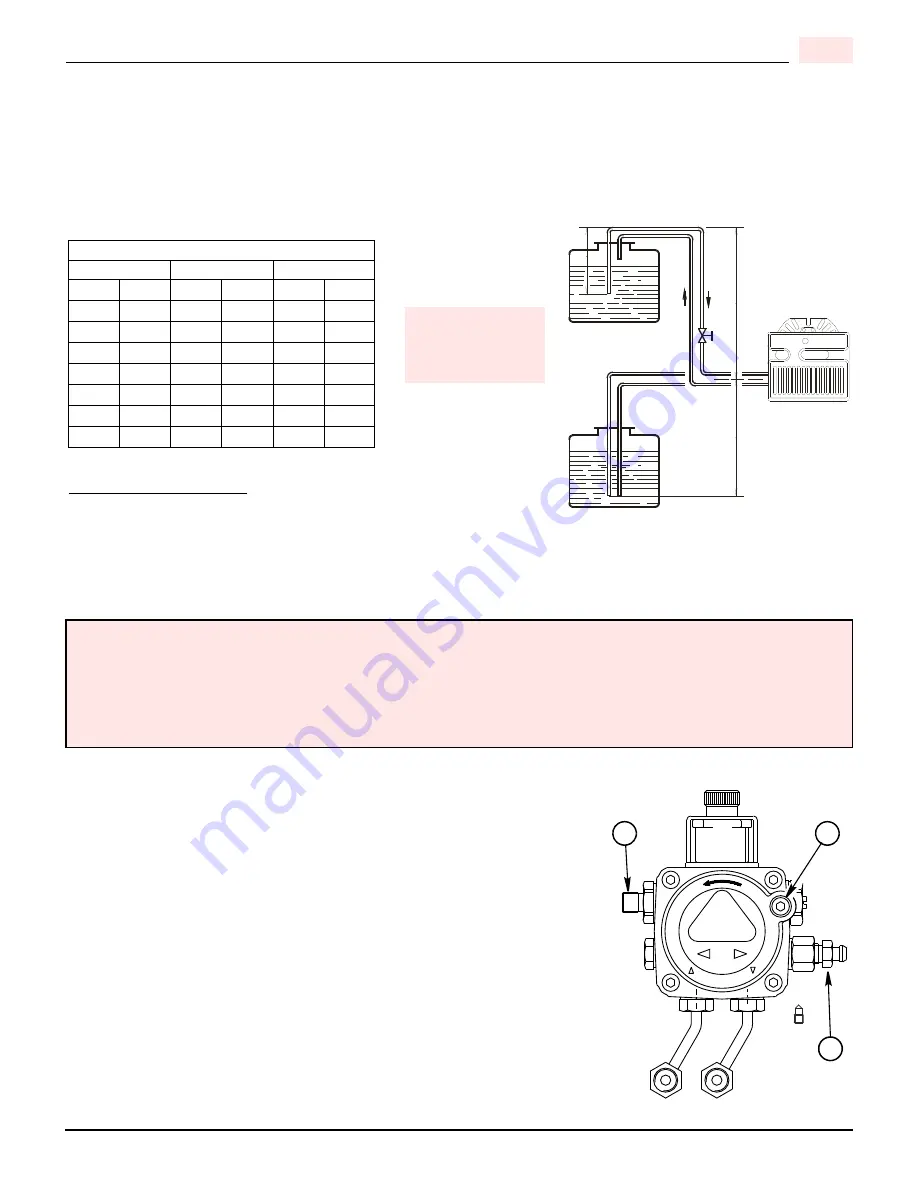

TWO LINE (LIFT SYSTEM)

A) If a two-line system is required, install the By-pass plug provided. The by-pass plug is installed in the return port

of the pump. A 2.5-mm hexagonal key provided with the by-pass plug is to be used to install the plug.

DO NOT use an inch size hexagonal key; damage to the by-pass plug may result.

When operating on a two-line system, supply and return lines should be the same diameter and both

should

extend to the same depth inside the fuel tank

. Be sure there are no air leaks or blockages in the piping sys-

tem. Any obstructions in the return line will cause failure of the pump shaft seal.

PUMP PURGE

NOTE:

To protect the pump gears, it is advisable to lubricate the pump prior

to purging a lift system. Apply oil through the VACUUM PORT (C).

A) SINGLE LINE (GRAVITY FEED SYSTEM)

I. Loosen the bleeder valve (A) until oil flows out. Tighten the bleeder valve

securely and startburner.

II. When bleeding the pump by pressure:

1) Loosen the bleeder valve (A).

2) Disconnect nozzle oil supply line at the pump nozzleport (B).

3) Attach a flexible plastic tube to the pump nozzle, port directing the oil

flow into a bucket.

4) Loosen the screw(s) securing the air tube cover, allowing it to be re-

moved freely.

5) Holding the air tube cover in its proper location start the burner.

6) When the solenoid valve is engaged approximately 10 seconds after

starting, remove the air tube cover and shine a light source on the

photocell, allowing it to see false light.

WARNING:

- Pipe dope or Teflon tapes are NOT to be used on any direct oil connection to the fuel pump.

- The height ‘P’ in Pipe Length Charts should not exceed 13 feet (4 m).

- The vacuum should not exceed 11.44 inches of mercury.

IMPORTANT:

An external, appropriately listed and certified oil filter must be placed in the fuel line between the fuel tank

and the burner pump.

To install the by-pass plug:

1) Remove the return plug (7).

2) Install the by-pass plug (4) using the 2.5 mm hexagonal key.

B) Attach the two PIPE CONNECTORS (6) to the pump SUPPLY and pump RETURN PORTS (5 and 7). Attach the re-

quired piping to these two pipe connectors using the NPT/ METRIC ADAPTERS that are supplied with the burner.

2 LINE (LIFT) SYSTEM-PIPE LENGTHS

H

3/8” OD

1/2” OD

FT

M

FT

M

FT

M

0.0

0.0

115

35

330

100

1.5

0.5

100

30

330

100

3.0

1.0

80

25

330

100

5.0

1.5

65

20

295

90

6.5

2.0

50

15

230

70

9.5

3.0

25

8

100

30

11

3.5

20

6

65

20

D6008

H

P

H

ATTENTION:

do not exceed

pipe lengths

indicated in chart!

D7284

C

A

B