20146103

16

GB

Installation

5.8

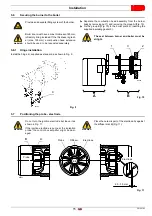

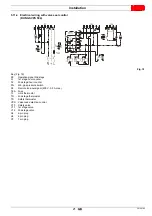

Combustion head adjustment

To adjust, proceed as follows:

loosen the screw A)(Fig. 12), move the elbow B) so that the

rear plate of the coupling (C) coincides with the set point;

tighten the screw A).

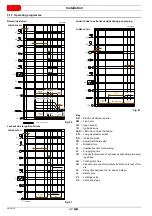

Example:

The burner is installed in a 40 kW boiler.

Considering efficiency of 90% the burner must supply around 44

kW.

The diagram (Fig. 13) shows that for this output the adjustment

must be made on notch 3.

The diagram is to be used only for initial settings,. To ensure

good air pressure switch operation it may be necessary to reduce

this combustion head opening (notch toward pos. 0).

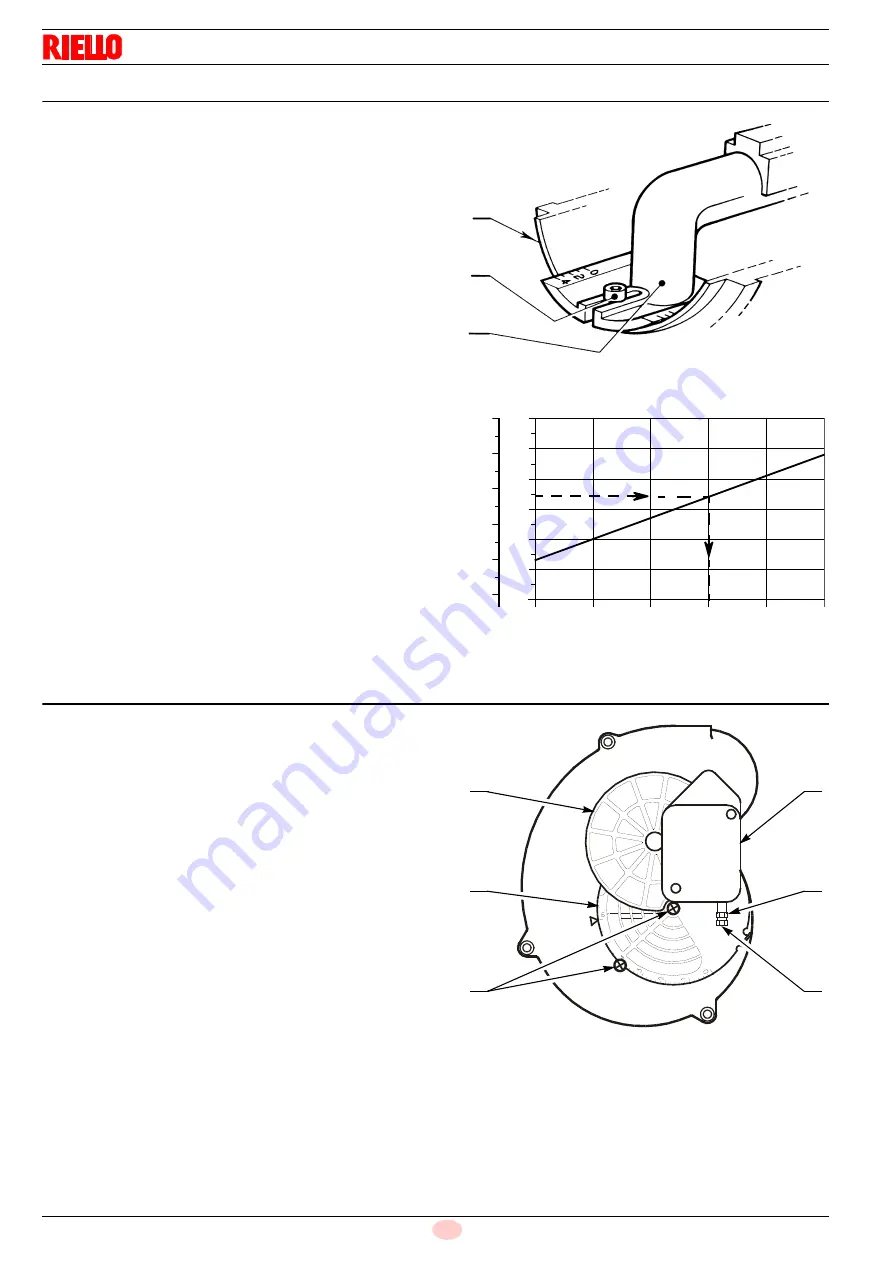

5.9

Air dampers adjustment

To adjust, proceed as follows:

Take the burner to the 2nd stage.

The mobile air damper 1)(Fig. 14), activated by the motor 2),

ensures the suction inlet opens completely.

Adjust 2nd stage air delivery using the fixed damper 3) after

loosening the screws 4).

Once optimal adjustment has been attained, fully screw in

the screws 4).

The damper leaves the factory set at pos.6, as shown in Fig. 14.

Take the burner to the 1st stage.

The mobile air damper (1) returns to the standby position.

Adjust 1st stage air delivery by turning the screw (6) after

loosening the nut (5) by turning it in a clockwise direction.

Once the ideal setting has been reached, block the nut (5)

by turning it in an anticlockwise direction.

C

A

B

S7015

Fig. 12

Fig. 13

kcal/h

kW

D5137

Notch No.

70

50

40

30

20

10

60

40,000

50,000

30,000

20,000

10,000

60,000

0

2

1

3

4

5

44

Fig. 14

D5074

1

3

2

6

5

4

Summary of Contents for 40 FS5D

Page 2: ...Translation of the original instructions...

Page 41: ......

Page 42: ......

Page 43: ......