20146103

32

GB

Installation

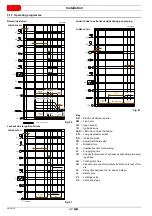

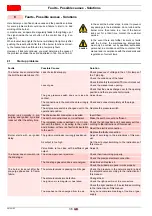

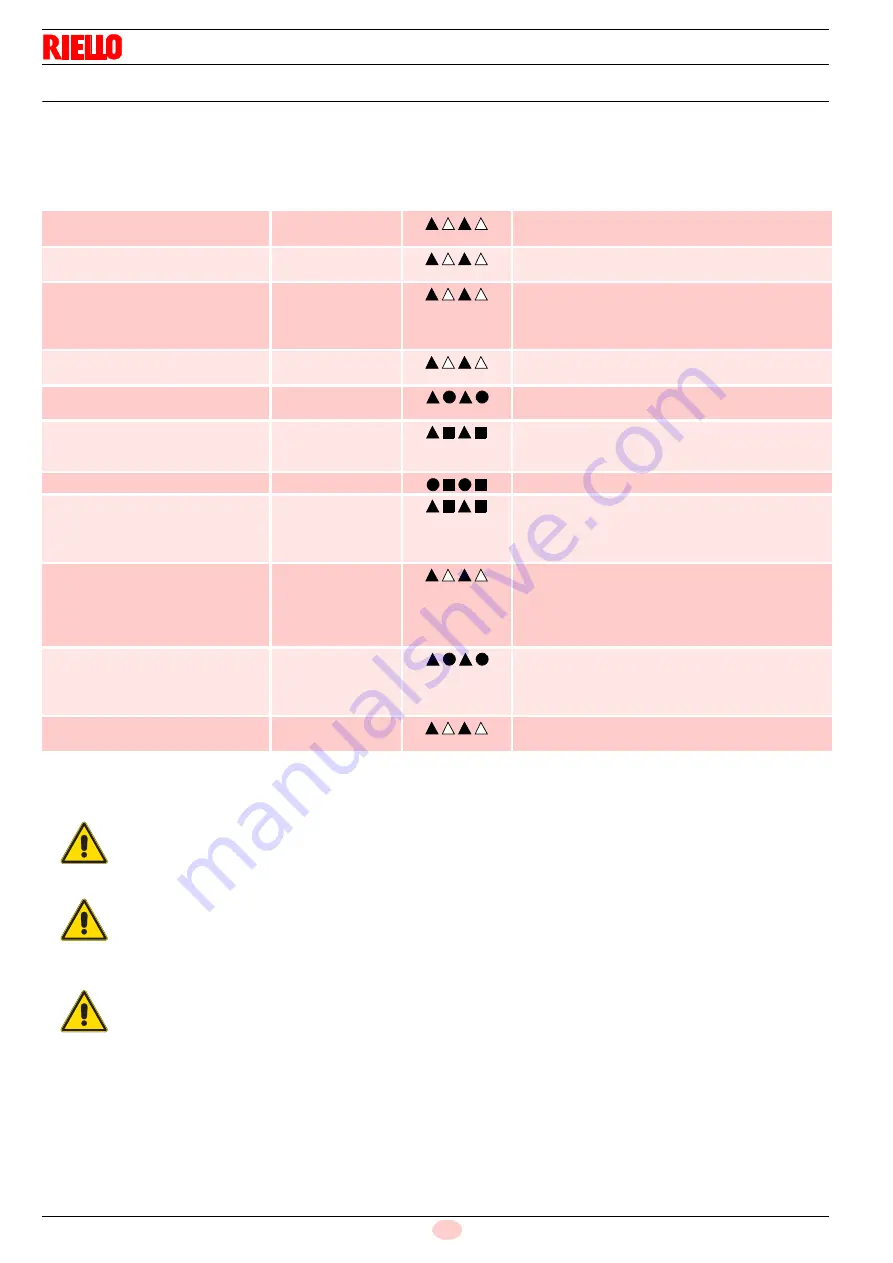

5.15 Lockout types

Whenever a lockout occurs, the control box shows the reasons

for the fault (and the reasons can be identified by the reset button

colour).

The sequence of pulses issued by the control box of the LED in

the reset button identifies the possible types of fault, which are

listed in the table below:

Tab. N

Blink frequency of the reset button for status indication (see par-

agraph

“Fault diagnostics - lockouts”

Lockout description

Lockout time

Led colour

Possible cause

Presence of parasite flame during

stand-by

After 25 seconds

-

presence of a false flame after heat request or

during post-purging

Detection of parasite flame during

pre-purging

After 1 second

-

presence of false flame signal during pre-purging

The flame is not detected after the

safety time

3 seconds after the

activation of the gas

valve

-

ionisation probe faulty or not connected

-

gas valve

-

faulty ignition transformer

-

badly regulated burner

Flame failure during operation

After 3 recycles

-

burner not calibrated correctly

-

ionisation probe faulty

Fan motor error

Immediate

-

faulty fan motor

-

fan motor not connected

Fault with the internal control of the

1st stage gas valve

Immediate

-

gas valve

-

internal control circuit of the 1st stage gas valve

faulty

Eeprom error

Immediate

-

faulty internal memory

Lockout due to air pressure switch

not closing after a heat request or af-

ter a recycle due to flame loss during

operation

After 15 seconds

-

the air pressure is too low, (the head has been

poorly adjusted)

-

The air pressure switch is defective: change it

Lockout for loss of air pressure or af-

ter repetition of the pre-purging due

to loss of air, or 10 sec before the end

of the pre-purging, or during the safe-

ty time, or during normal operation

After 1 second

-

the air pressure is too low, (the head has been

poorly adjusted)

-

the air pressure switch is defective: change it

Lockout due to air pressure switch al-

ready switched to closing of the heat

request thermostat or after a recycle

due to flame loss during operation

After 120 seconds

-

the air pressure switch is changed over to the op-

erational position, change the pressure switch

-

the fan motor continues to be powered, check

the lockout of the flame control

Fault with the internal control circuit

of the 2nd stage gas valve

Immediate

-

internal control circuit of the 2nd stage gas valve

faulty

WARNING

To reset the control box after visual diagnostics

have been displayed, you must press the reset

button.

WARNING

In the event the burner stops, in order to prevent

any damage to the installation, do not unblock the

burner more than twice in a row. If the burner

locks out for a third time, contact the customer

service.

DANGER

In the event there are further lockouts or faults

with the burner, the maintenance interventions

must only be carried out by qualified, authorised

personnel, in accordance with the contents of this

manual and in compliance with the standards and

regulations of current laws.

Summary of Contents for 40 FS5D

Page 2: ...Translation of the original instructions...

Page 41: ......

Page 42: ......

Page 43: ......