17

20063754

GB

Installation

5.10

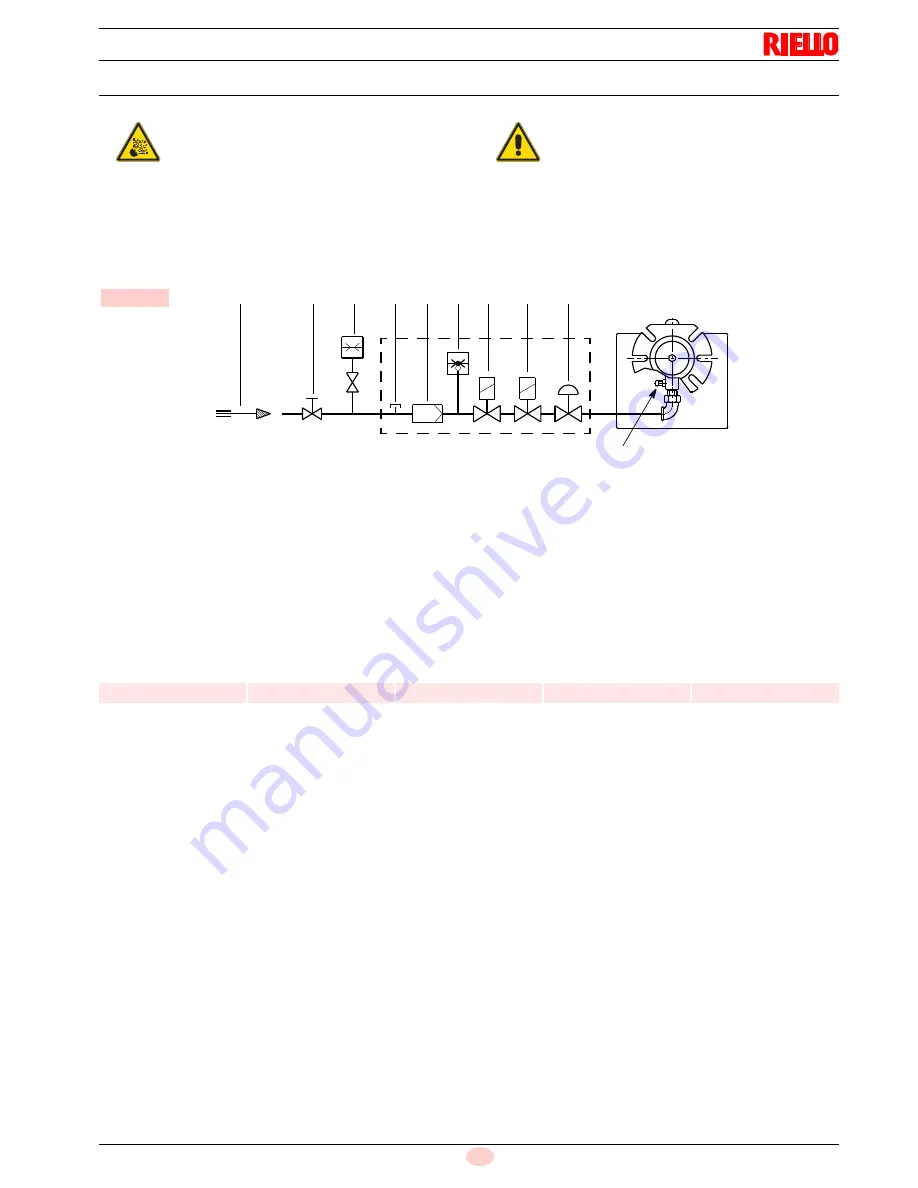

Gas feeding

5.10.1 Gas feeding line

Key (Fig. 14)

1

Gas input pipe

2

Manual gate (the responsibility of the installer)

3

Gas pressure gauge (the responsibility of the installer)

4

Filter

5

Gas pressure switch

6

Safety valve

7

Pressure stabiliser

8

Adjustment valve

M1 Gas-supply pressure test point on the gas pressure switch

M2 Pressure coupling test point

5.10.2 Gas train

Approved according to standard EN 676 and provided separately

from the burner. Supplied separately for its adjustment, see the

enclosed instructions.

The train-burner combination is indicated in Tab. C.

Tab. C

Explosion danger due to fuel leaks in the pres-

ence of a flammable source.

Precautions: avoid knocking, attrition, sparks and

heat.

Make sure the fuel interception tap is closed be-

fore performing any operation on the burner.

WARNING

The fuel supply line must be installed by qualified

personnel, in compliance with current standards

and laws.

Fig. 14

1

D7733

M2

2

3

M1

4

5

6

8

7

MBC 65/1

Code

Model

Connections

Use

Gas train

Burner

3970569

MBC 65/1 - RSD 20

Rp 1/2

Rp 1/2

Natural gas and LPG