5

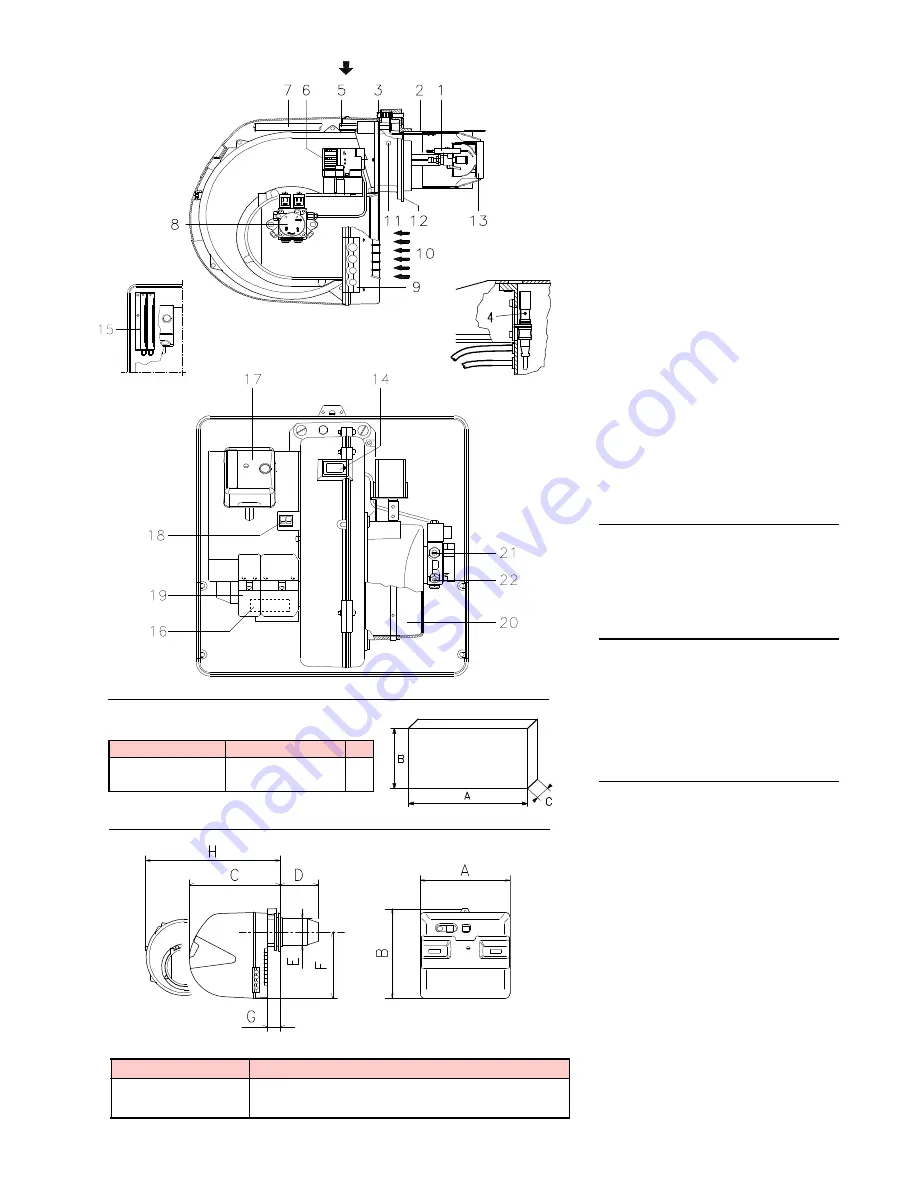

BURNER DESCRIPTION (A)

1 Ignition electrodes

2 Combustion head

3 Screw for combustion head adjustment

4 UV Sensor for flame presence control

5 Screw for fixing fan to flange

6 Servomotor

7 Slide bars for opening the burner and inspect-

ing the combustion head

8 Pressure stage pump

9 Plate prearranged to drill 4 holes for the pas-

sage of hoses and electrical cables.

10 Air inlet to fan

11 Fan pressure test point

12 Boiler mounting flange

13 Flameholder

14 Flame inspection window

15 Extensions for slide bars 7)

16 Motor capacitor

17 Control box with lock-out pilot light and lock-

out reset button

18 Two switches:

- one "burner off - on"

- one for "1st - 2nd stage operation"

19 Plugs for electrical connections

20 Air gate valve

21 Pump adjustment (low pressure)

22 Pump adjustment (high pressure)

NOTE

If the control box 17)(A) pushbutton lights up, it

indicates that the burner is in lock-out.

To reset, press the pushbutton, no sooner than

10 s after the lock-out.

PACKAGING - WEIGHT (B)

Approximate measurements

• The burners are shipped in cardboard boxes

with the maximum dimensions shown in table

(B).

• The weight of the burner complete with pack-

aging is indicated in table (B).

MAX. DIMENSIONS (C)

Approximate measurements

The maximum dimensions of the burner are giv-

en in (C).

Bear in mind that inspection of the combustion

head requires the burner to be opened and the

rear part withdrawn on the slide bars.

The maximum dimension of the burner, without

casing, when open is give by measurement H.

STANDARD EQUIPMENT

2 - Flexible hoses (L = 1530 mm)

2 - Gaskets for flexible hoses

2 - Nipples for flexible hoses

1 - Thermal insulation screen

4 - Screws to secure the burner flange to the

boiler: M8 x 25

3 - Fairleads for electrical connections

1 - Instruction booklet

1 - Spare parts list

(B)

mm

A

B

C

Kg

RL 22 BLU

850

550

540

40

RL 32 BLU

850

550

540

41

mm

A

B

C

D

E

F

G

H

RL 22 BLU

476

474

468

276

140

352

52

604

RL 32 BLU

476

474

468

293

140

352

52

604

(C)

(A)

D1861

D10321

D88

D1862

D1866

Partial view from

H

H

D10320