20023724

7

GB

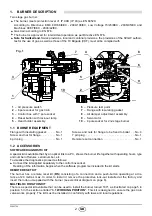

3.4

GAS TRAIN,

(as EN 676)

The gas train is supplied separately, for its adjustment see the enclosed instructions.

3.5

GAS TRAIN ELECTRICITY SUPPLY

The gas train’s power cables can be fed to the right or

left of the burner, as illustrated in figure 6.

Depending on the entry point, the cable clamp with

pressure test point (1) and simple cable clamp (2) may

need swapping over.

Consequently, you must make sure:

cable clamp (1) is positioned correctly;

the tube is positioned correctly so that there are no

restrictions likely to impede air flowing to the pres-

sure switch.

WARNING

If necessary, cut the tube to the right size.

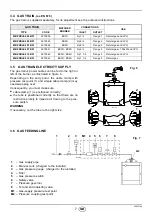

3.6

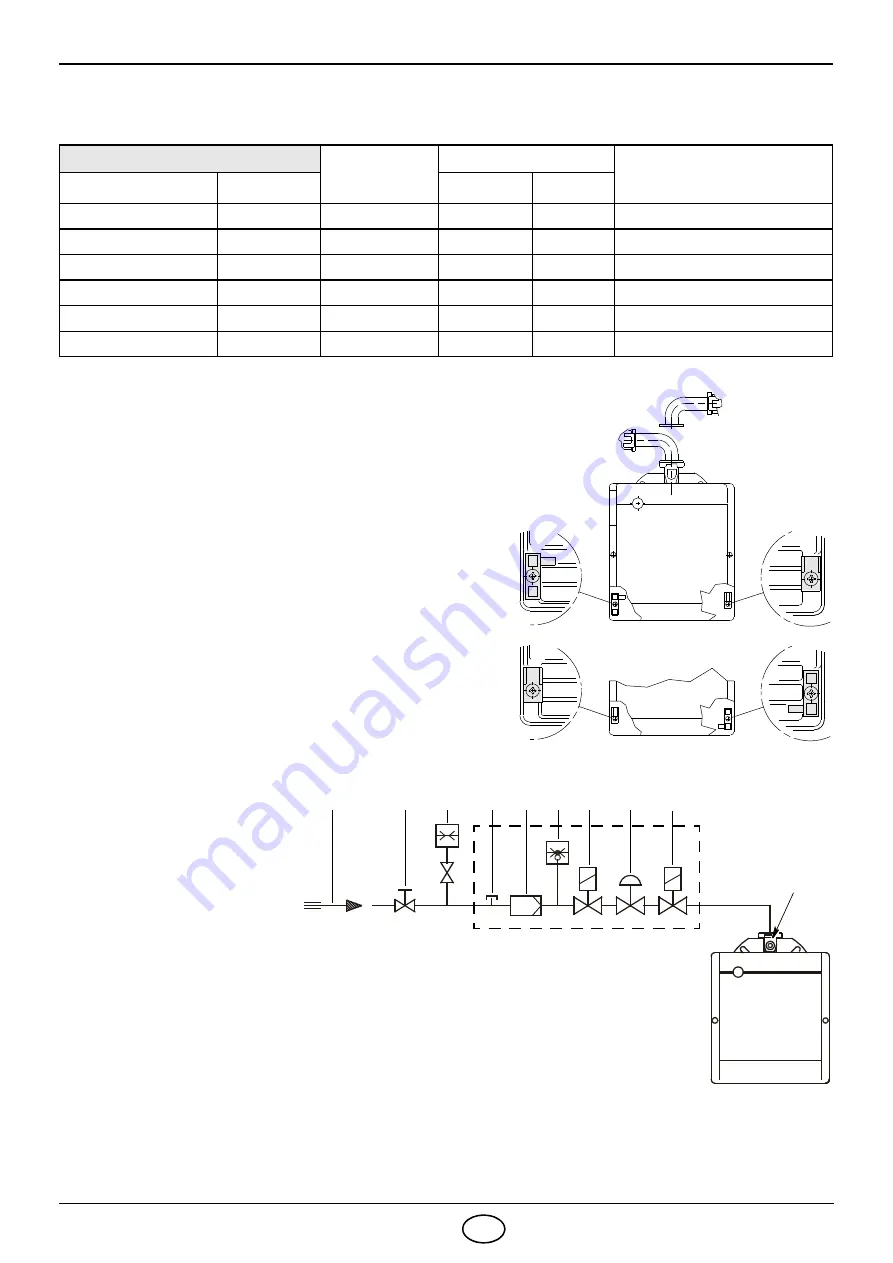

GAS FEEDING LINE

GAS TRAIN

MATCHED

BURNER

CONNECTIONS

USE

TYPE

CODE

INLET

OUTLET

MB ZRDLE 405 B01

3970539

BS1D

Rp 1/2

Flange 1

Natural gas and LPG

MB ZRDLE 405 B01

3970540

BS2D

Rp 3/4

Flange 2

Natural gas and LPG

MB ZRDLE 407 B01

3970538

BS2D

Rp 3/4

Flange 2

Natural gas and LPG

MB ZRDLE 407 B01

3970541

BS3D - BS4D

Rp 3/4

Flange 3

Natural gas

150kW and LPG

MB ZRDLE 410 B01

3970542

BS3D - BS4D

Rp 1 1/4

Flange 3

Natural gas and LPG

MB ZRDLE 412 B01

3970543

BS3D - BS4D

Rp 1 1/4

Flange 3

Natural gas

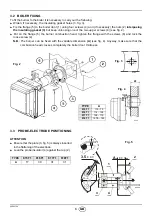

2

1

2

1

Fig. 6

D7113

1

– Gas supply pipe

2

– Manual cock (charged to the installer)

3

– Gas pressure gauge (charged to the installer)

4

– Filter

5

– Gas pressure switch

6

– Safety

valve

7

– Pressure

governor

8

– 1st and 2nd adjusting valve

M1

– Gas-supply pressure test point

M2

– Pressure coupling test point

M2

Fig. 7

D5209

1

2

3

M1

5

6

7

4

8

Summary of Contents for BS1D

Page 2: ......

Page 31: ...20023724 13 6 4 1 2 6 1 4 6 7 7 L1 N 1 2 1 2 1 2 1 2 1 1 1 3 4 4...

Page 32: ...20023724 14 CN 3 2 2 2 13 9 9 9 4 2...

Page 33: ...20023724 15 CN 6 2 4...

Page 34: ...20023724 16 CN 7 7 1 7 2...

Page 35: ......