Installation

23

20102152

GB

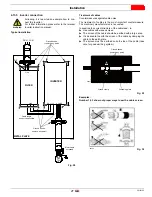

4.12.3 Gas pressure

The diagram (Fig. 22) show minimum load losses at combustion

head depending on the maximum burner output operation with nat-

ural gas (G 20).

Gas pressure is measured at the test point 1)(Fig. 23), with:

•

Combustion chamber at 0 mbar

•

Burner working at maximum output

•

Ring nut 2) (Fig. 17) adjusted as in the diagram of Fig. 16

NOTE

To know the approximate output at which the burner is operating at

its maximum:

–

subtract the combustion chamber pressure from the gas pres-

sure measured at test point 1)(Fig. 23);

–

find, in the diagram (Fig. 22) the pressure value closest to the

result you want;

–

read the corresponding output on the left.

Example

• Maximum output operation

• Natural gas

• Gas ring 2)(Fig. 16 at page 20) adjust as indicated in diagram

•

Gas pressure at test point 1)(Fig. 23)

= 5.11 “WC

•

Pressure in combustion chamber

= 1.18 “WC

5.11 - 1.18

= 3.93 “WC

A maximum output of 3030 MBtu/hr shown diagrams corresponds

to 3.93 “WC pressure.

This value serves as a rough guide, the effective delivery must be

measured at the gas meter.

NOTE

To know the required gas pressure at test point 1) (Fig. 23), set the

maximum output required from the burner operation, then:

–

find the nearest output value in the table for the burner in ques-

tion.

–

read, on the diagram (Fig. 22), the pressure test point 1)

(Fig. 23);

–

add this value to the estimated pressure in the combustion

chamber.

Example

•

Maximum output required: 3750 MBtu/hr

•

Ring nut 2) (Fig. 17) adjusted as in the diagram of Fig. 16

•

Gas pressure at output of 2815 MBtu/hr

=

6 “WC

•

Pressure in combustion chamber

= 1.18 “WC

6 + 1.18

= 7.15 “WC

pressure required at pressure test point 1) (Fig. 23).

p “wc gas butterfly 2)(Fig. 23)

Tab. I

MBtu/hr

kW

p “WC

2047

600

0.1

2218

650

0.1

2440

715

0.2

2593

760

0.2

2815

825

0.2

3037

890

0.2

3258

955

0.2

3480

1020

0.3

3719

1090

0.3

3992

1170

0.3

4265

1250

0.4

4335

1300

0.5

4606

1350

0.5

4777

1400

0.5

Fig. 22

Burner output operation

D3182

p (“W

C

)

Fig. 23

1

2

D2441