20102152

22

GB

Installation

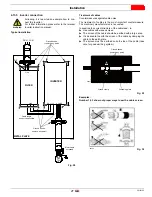

4.12 Gas feeding

4.12.1 Gas feeding line

It must be type-approved according to required standards and is

supplied separately from the burner.

Key (Fig. 20)

1

Gas input pipe

2

Manual valve

3

Pressure regulator

4

Minimum gas pressure switch

5

1st safety shut off valve

6

2nd safety shut off valve

7

Standard issue burner with flange gasket

8

Gas adjustment butterfly valve (*)

9

Burner

10 Maximum gas pressure switch (*)

(*) On the burner

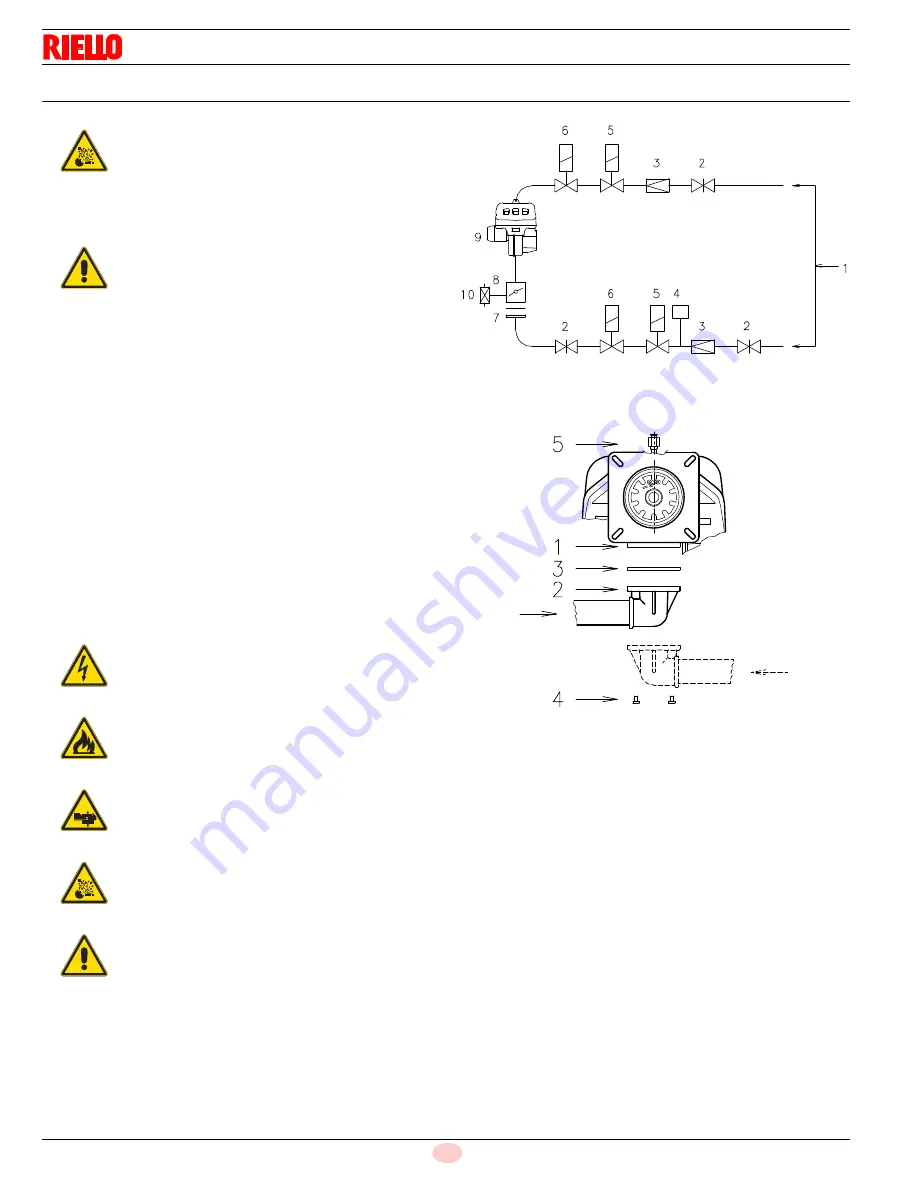

4.12.2 Gas train

The gas train can enter the burner from the right or left side, de-

pending on which is the most convenient, see Fig. 21.

The gas train must be connected to the gas attachment 1)(Fig. 21)

with the flange 2), the gasket 3) and the screws 4) supplied with the

burner.

The gas solenoids must be as close as possible to the burner, to

ensure that the gas reaches the combustion head within the safety

time of 3s.

Ensure that the maximum pressure necessary for the burner is in-

cluded in the calibration field of the pressure regulator (colour of the

spring).

The pilot gas train must be connected to the gas attachment

5)(Fig. 21) and can enter the burner from the right or left side.

Explosion danger due to fuel leaks in the presence

of a flammable source.

Precautions: avoid knocking, attrition, sparks and

heat.

Make sure that the fuel interception tap is closed

before performing any operation on the burner.

WARNING

The fuel supply line must be installed by qualified

personnel, in compliance with current standards

and laws.

DANGER

Disconnect the electrical power using the main sys-

tem switch.

Check that there are no gas leaks.

Beware of train movements: danger of crushing of

limbs.

Make sure that the gas train is properly installed by

checking for any fuel leaks.

WARNING

See the accompanying instructions for the adjust-

ment of the gas train.

Fig. 20

D2438

GAS PILOT LINE

MAIN GAS LINE

Fig. 21

D2393