2916050

14

GB

Installation

4.4

Operating position

4.5

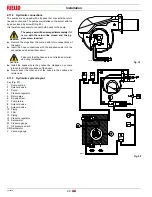

Preparing the boiler

4.5.1

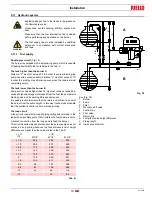

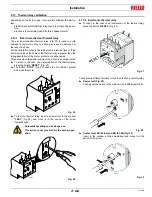

Boring the boiler plate

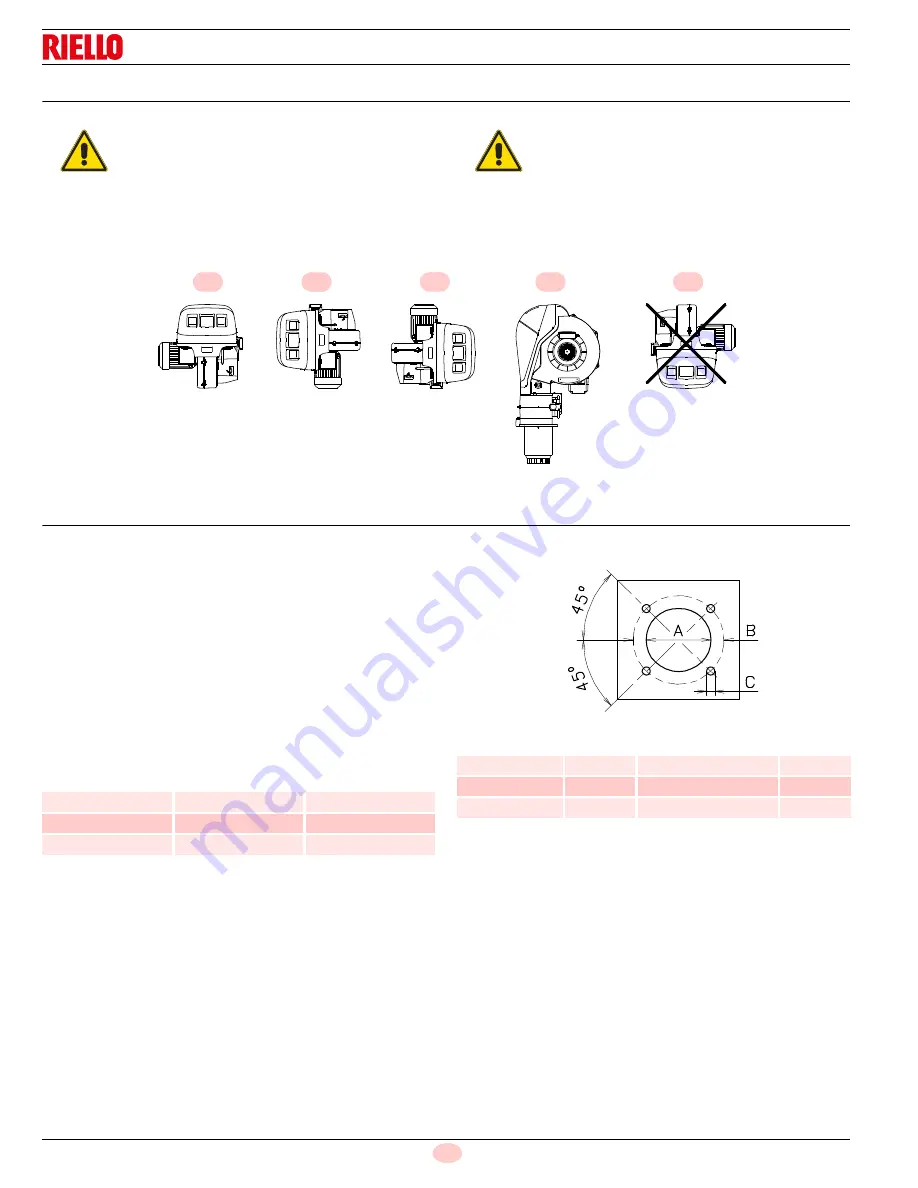

Drill the combustion chamber mounting plate as shown in Fig. 7.

The position of the threaded holes can be marked using the head

gasket supplied with the burner.

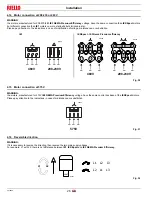

4.5.2

Length of the blast tube

The length of the blast tube must be selected according to the indi-

cations provided by the manufacturer of the boiler, and it must be

greater than the thickness of the boiler door complete with its insu-

lation.

The range of lengths available, L (inch), is as in the Tab. I:

Tab. I

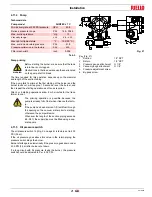

For boilers with front flue passes 12)(Fig. 8) or flame inversion

chambers, protective insulation material 10) must be inserted be-

tween the boiler refractory 11) and the blast tube 9).

This protective insulation must not compromise the extraction of

the blast tube.

For boilers having a water-cooled front the insulation 10)-11)(B) is

not required unless it is required by the boiler manufacturer.

Tab. J

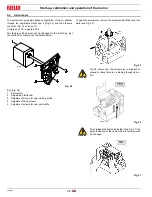

WARNING

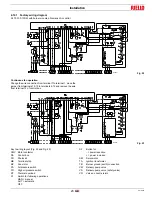

The burner is designed to operate only in posi-

tions

1

,

2

,

3

and

4

(Fig. 6).

Installation

1

is preferable, as it is the only one

that allows the maintenance operations as

described in this manual.

Installations

2

,

3

and

4

permit operation but

make maintenance and inspection of the com-

bustion head more difficult.

DANGER

Any other position could compromise the cor-

rect operation of the appliance.

Installation

5

is prohibited for safety reasons.

Fig. 6

2

3

4

5

1

D7739

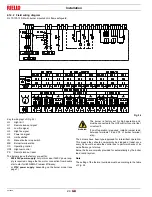

Model

Short blast tube

Long blast tube

(with kit)

RL 70/M

10 23/32”

15 5/32”

RL 100/M

10 23/32”

15 5/32”

RL 130/M

10 23/32”

15 5/32”

inch

A

B

C

RL 70/M

7 9/32”

10 27/32” - 12 13/16”

1/2 W

RL 100/M

7 9/32”

10 27/32” - 12 13/16”

1/2 W

RL 130/M

7 21/32”

10 27/32” - 12 13/16”

1/2 W

Fig. 7

D455