Start-up, calibration and operation of the burner

27

2916050

GB

5.1

Notes on safety for the first start-up

5.2

Burner calibration

The optimum calibration of the burner requires an analysis of the

flue gases at the boiler outlet.

The following settings that have already been made do not require

modification under normal circumstances:

5.2.1

Combustion head setting

5.2.2

Nozzle adjustment

5.2.3

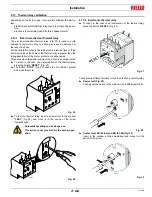

Electrode position

Refer to Fig. 15.

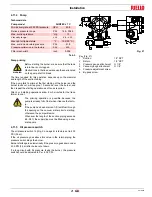

5.2.4

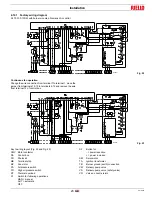

Servomotor, cams I - II - III

Refer to page 28.

5.3

Burner starting

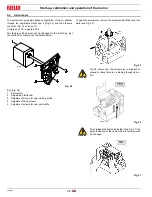

Close the control circuit, with the switches in Fig. 38 and Fig. 33 in

the “

AUTO

” position.

On firing turn the switch (Fig. 38) to “

MAN

”.

5.3.1

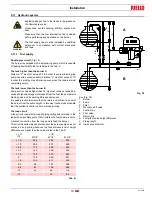

Maximum output

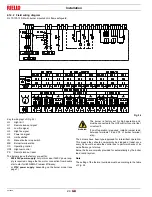

Using button B)(Fig. 38), “increase output” until it stops at app.

130° (cam 1).

Place the slide switch on MAX and set the relative MAX trim poten-

tiometer (setting must be very near to 130°) to exploit as far as pos-

sible the variable profile cam 2)(Fig. 34).

The setting of the oil delivery must be made on the variable eccen-

tric 6)(Fig. 14 on page 17) by turning the screw 5)(Fig. 14 on

page 17).

The air setting must be made on the variable profile cam 2)(Fig. 34)

after loosening the screws 4)(Fig. 34) by turning the screws 3).

5.3.2

Minimum output

With the slide switch on the “

OPE

” position, use button B)(Fig. 38)

“decrease output” until it stops at app. 20° (cam 3).

Put the slide switch in the MIN position and set the modulation min-

imum using the relative MIN trim potentiometer.

The setting of the oil delivery must be made on the nut and lock-nut

4)(Fig. 14 on page 17) and, if necessary, on the variable eccentric

6)(Fig. 14 on page 17).

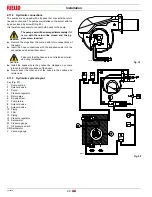

5.3.3

Intermediate outputs

With the switch C)(Fig. 38) in the “

AUTO

” position, the slide switch

in the “

OPE

” position and the switch 1)(Fig. 33) in the “

MAN

” posi-

tion, move the button 2)(Fig. 33) in various intermediate levels be-

tween maximum and minimum and set the variable profile cam

2)(Fig. 34) to achieve optimum combustion, by turning the

screws 3)(Fig. 34).

If possible, do not change the previously set maximum and mini-

mum levels.

When the setting is complete, lock the cam profile using screws

4)(Fig. 34).

5

Start-up, calibration and operation of the burner

WARNING

The first start-up of the burner must be carried out

by qualified personnel, as indicated in this manual

and in compliance with the standards and regula-

tions of the laws in force.

WARNING

Check the correct working of the adjustment, com-

mand and safety devices.

WARNING

When the eccentricity is modified, it is necessary to

bring back to MAX and check the setting again.

The setting must be made on the adjustable profile

cam 2)(Fig. 34).

WARNING

Do not change the eccentric, already adjusted for

MAX and MIN.

Check the various setting levels with a combustion

analysis.

Make a progressive setting of the profile, without

sharp changes.

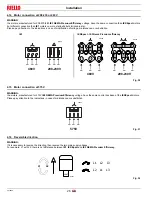

Fig. 33

1

2

D791