2916050

16

GB

Installation

4.7

Nozzle

The burner complies with the emission requirements of the UL 296

Standard.

In order to guarantee that emissions do not vary, recommended

and/or alternative nozzles specified by the manufacturer in the In-

struction and warning booklet should be used.

4.7.1

Recommended nozzles

Type A4 return flow nozzles - 45° angle

4.7.2

Nozzle assembly

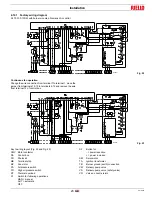

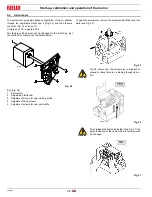

At this stage of installation the burner is still disassembled from the

blast tube; it is therefore possible to fit the nozzle with the box

wrench 1)(Fig. 10), inserting the wrench through the central hole in

the flame stability disk.

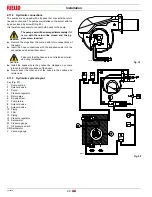

Finally remount the burner 3)(Fig. 11) on the slide bars 2) and slide

it up to the flange 5), keeping it slightly raised to prevent the flame

stability disk from pressing against the blast tube.

Tighten the screws 1) on the slide bars 2) and screws 4) fixing the

burner to the flange.

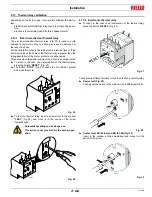

If it proves necessary to change a nozzle with the burner already

fitted to the boiler, proceed as outlined below:

pull back the burner on its slide bars as shown in Fig. 8;

remove the nuts 1)(Fig. 12) and the disk 2);

use wrench 3)(Fig. 12) to change the nozzles.

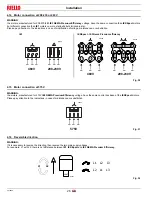

4.7.3

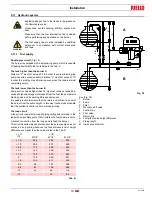

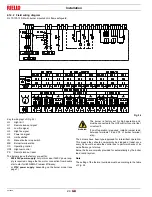

Choice of nozzle

In case an intermediate delivery between the two values indicated

in the diagram (Fig. 13) is required, a nozzle with higher delivery

must be chosen.

NOTE:

the values indicated in the right side of the diagram (Fig. 13),

refer to the data printed on the nozzle.

Delivery reduction will be obtained by means of the pressure regu-

lator.

WARNING

It is advisable to replace nozzles every year during

regular maintenance operations.

CAUTION

The use of nozzles other than those specified by the

manufacturer and inadequate regular maintenance

may result into emission limits non-conforming to

the values set forth by the regulations in force, and

in extremely serious cases, into potential hazards to

people and objects.

The manufacturing company shall not be liable for

any such damage arising from nonobservance of

the requirements contained in this manual.

WARNING

Do not use any sealing products such as gas-

kets, sealing compound, or tape.

Be careful to avoid damaging the nozzle seal-

ing seat.

Fig. 10

D1220

D1221

Fig. 11

D1222

Fig. 12

D2355

Fig. 13

N

ozzl

e fl

ow

rat

e

-

GPH

Return pressure -

PSI