Installation

21

20026767

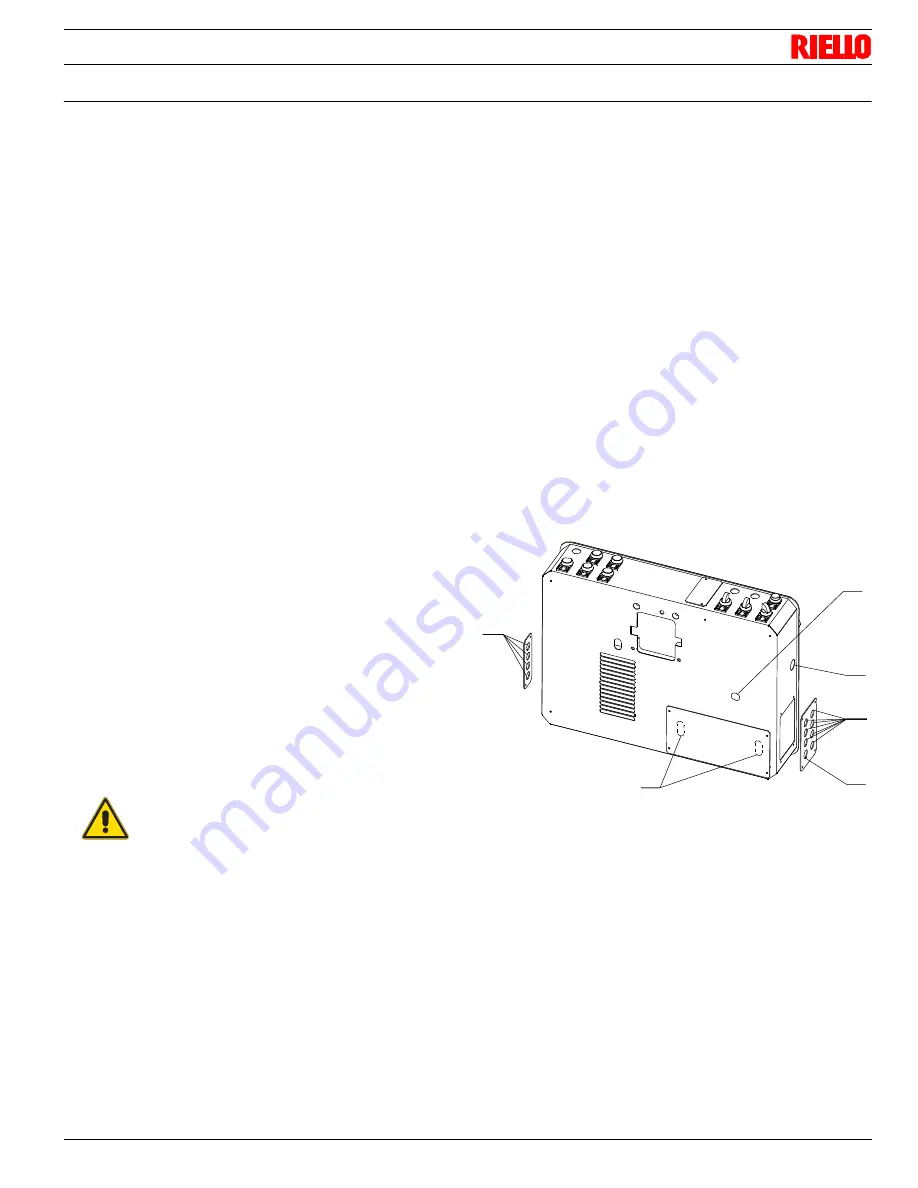

4.12 Electrical wiring

Notes on safety for the electrical wiring

If the hood is still present, remove it and proceed with the elec-

trical wiring.

All the cables to be connected to the burner are fed through the

grommets.

The use of the cable grommets can take various forms.

By the way of example we indicate the following mode (Fig. 20)

(according to

UL795

):

1

Three phase power supply with

1

/

2

”

cable grommet (no single

phase);

2

Single phase power supply with

1

/

2

”

cable grommet.

Available:

Consents/safety, minimum gas pressure switch, gas valves

and other devices with

3

/

8

”

cable grommet.

3

Available: maximum gas pressure switch (kit) and other

4

Horn

5

Available: step down transformer

The electrical wiring must be carried out with the electrical supply disconnected.

Electrical wiring must be carried out by qualified personnel and in compliance with the regulations currently in force in

the country of destination. Refer to the electrical layouts.

The manufacturer declines all responsibility for modifications or connections different from those shown in the electri-

cal layouts.

Check that the electrical supply of the burner corresponds to that shown on the identification label and in this

manual.

Do not invert the neutral with the phase in the electrical supply line.

Any inversion would cause a lockout due to firing failure.

The electrical safety of the device is obtained only when it is correctly connected to an efficient earthing system,

made according to current standards.

It is necessary to check this fundamental safety requirement. In the event of doubt, have the electrical system

checked by qualified personnel.

Do not use the gas tubes as an earthing system for electrical devices.

The electrical system must be suitable for the maximum input power of the device,as indicated on the label and in the

manual, checking in particular that the section of the cables is suitable for the input power of the device.

For the main power supply of the device from the electricity mains:

- do not use adapters, multiple sockets or extensions;

- use an omnipolar switch with an opening of at least

1

/

8

” (overvoltage category) between the contacts, as indicated

by the current safety standards.

Do not touch the device with wet or damp body parts and/or in bare feet.

Do not pull the electric cables.

WARNING

The control panel is in compliance with UL508A.

Fig. 20

1

2

5

2

4

3

D10369

Summary of Contents for C9541400

Page 2: ......

Page 30: ...20026767 28 Appendix Spare parts A Appendix Spare parts...

Page 35: ......