29

CHAPTER

8

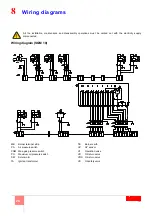

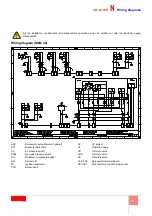

Wiring diagrams

Wiring diagram (SQM 40)

All the installation, maintenance and disassembly operations must be carried out with the electricity supply

disconnected.

!

"

!

"

#"$%$&"

"%$&&'

$(%$ #"

#"$ %$$"&

)

)

$

$

)

**#+

,

"

"

"

)

$

)

-

)

$

"

)

.

*

"

*

*

!

)

-

*

"

/*

)

"

$

$

$

*

)

$

$

"

"

0

)

$

"

"

"

"

"

*

1

'*

2

)

3&4&"4&"4&

(3$"4& (4$%4 #

'"3%&&4'"&& 45$"4"&

$3"!"4""$4"46$

!34"!4"4

#3%$ 4 #%"4&$ 4 "%

3$ %4$"4$"4$"

3%&"4%&"4%&"4%&"

'3%%4"'4%4

(34%$(4"4

!34&!44&!

/3 #""4/%"4/%"4(%&

3"$4%&"4"$4%&"

$'"3%&&4"!"4'"&& 4""$45$"4"4"&4$

$3$"4 $4$4$

ASZ

Servomotor potentiometer (optional)

XT1

Burner terminal strip

PA

Air pressure switch

PGM

Max. gas pressure switch

PO

Maximum oil pressure switch

SM

Servomotor

TA

Ignition transformer

XTB

Burner earth

UV

UV sensor

VF

Operation valve

VR

Oil return valve

VRS

Oil return valve

VS

Oil safety valve

X1-X2-X3

Servomotor terminal board

XS1-XP1

Servomotor connection plug-socket

Summary of Contents for DB 4 LSM C13

Page 2: ......

Page 61: ...1...

Page 69: ...9 3 3 1 1 2 3 M12 X 25 1 2 1 2 3 3 D12015 10 7 3 4 1 1 6 5 6 2 4 3 3 20110636...

Page 71: ...11 3 3 3 12 A A 8 10mm 4 4 5mm 12 D8665...

Page 72: ...12 4 4 1 1 2 3 3 3 4 1 6 13 1 3 4 5 D8416 2 6...

Page 73: ...13 4 4 2 D7543 C GF HPG LPG MM PA PGM PGm RG SRV VE VPS VR VS 0 5 4 bar 500 mbar 14...

Page 75: ...15 5 5 2 SQM 10 1 4 2 3 5 6 7 1 2 0 20 3 20 4 5 20 130 1 4 17 D1500...

Page 78: ...18 5 5 5 19 20 21 D2213 D2215 19 20 21 D2214...

Page 79: ...19 5 5 6 EN 267 20 A B D3509 22 2...

Page 83: ...23 7 7 1 UV 70 A 187 V 100 A c c 100 F 1V c c 7 2 1 2 3 4 5 1 2 3 4 5 6 D1143 31...

Page 86: ...26 7 VR VR VS VR...

Page 87: ...27 8 SQM 10 MB PA PGM PO SM TA TB UV UV VF VR VRS VS 3 5 6 7 6 3 2 8 5...

Page 89: ......

Page 90: ......

Page 91: ......