12

5

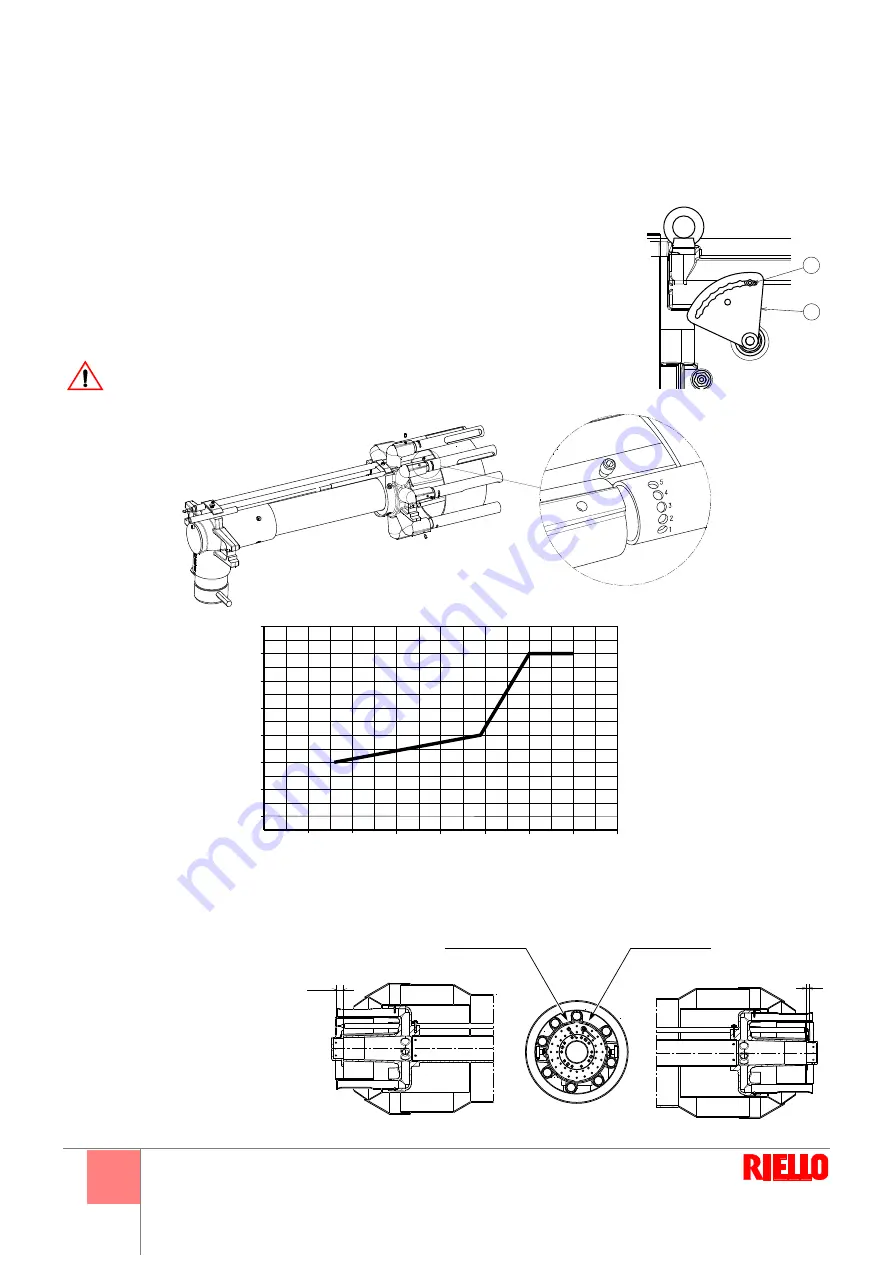

Preparation for start up

5.1

Combustion head setting

Loosen the screw 1) and turn the graduated sector 2) according diagrams Fig. 16. The system

allows an optimal setting even at a minimum firing rate. Combustion head opening can be var-

ied by moving the lever onto holes from 0 to 6, Fig. 14.

The choice of the hole (0 - 6) to be used is decided on the basis of diagram (Fig. 16) against the

required maximum output. Setting is pre-arranged in the plant for the maximum power (hole 6).

When dealing with boilers featuring a strong back pressure, if air delivery is insufficient even

with the damper fully open, you can use a different setting to that illustrated in diagram (Fig. 16)

- do this by moving the lever onto the next highest hole numerically speaking, thus increasing

the combustion head’s opening and hence air delivery.

For operation on flame-reversal boilers, gas pipes must be adjusted to hole

position 4, see Fig. 15.

5.2

Position of electrodes (Fig. 17)

Make sure that the electrode and

the probe are positioned as shown

in Fig. 17.

1

2

0

1

2

3

4

5

6

D8299

Fig. 14

Fig. 15

D3418

6

5

4

3

2

1

0

1000

0

1

2

3

4

5

6

1500

2000

2500

3000

3500

4000

4500

5000 k W

7

D8307

Fig. 16

7

18,5

Fig. 17

D3583

Electrode

Probe

Summary of Contents for DB 4 SM BLU

Page 2: ......

Page 39: ...1...

Page 48: ...10 4 4 1 D7543 C GF HPG LPG MM PA PGM PGm RG SRV VE VPS VR VS 0 5 4 bar 500 mbar 12...

Page 49: ...11 4 4 2 DANGER WARNING MB PA PGM SM SO TA TB D7904 13...

Page 51: ...13 5 5 3 1 4 2 3 5 6 7 1 2 0 3 20 4 5 20 130 1 4 5 4 130 19 18 D1500 3 2 4 1 19 1 2 3 4 D1499...

Page 52: ...14 5 MAN 3 1 130 90 2 19 2 19 20 2 2...

Page 54: ...16 5 5 7 6 A 100 A 5 8 1 2 3 4 5 1 2 3 4 5 6 D3097 23 A...

Page 55: ...17 6 6 1 1 2 3 VR VR VS VR WARNING DANGER...

Page 56: ...18 6...

Page 57: ......

Page 58: ......

Page 59: ......