20013749

6

GB

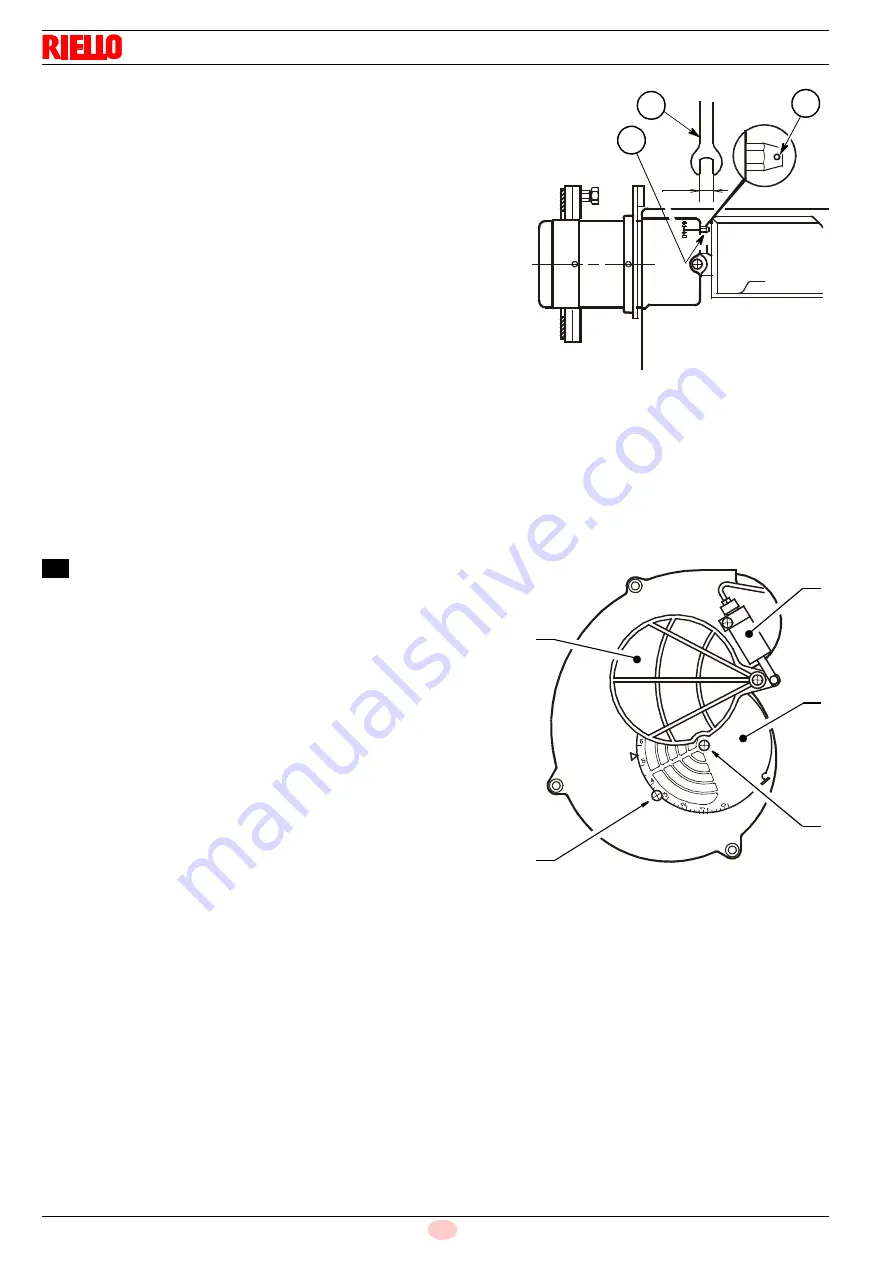

Combustion head settings indicated in the table are valid

for most cases.

The setting of the fan output according to the installation

should normally be done only through the air damper.

Should one subsequently want to retouch also the set-

ting of the combustion head, with the burner running,

operate on the rod (1, fig. 6) with a 6 mm spanner (2, fig.

6) as follows:

Turn to the right: (sign

+

), in order to increase the vol-

ume of air entering the combustion chamber and thus

diminishing its pressure.

There is a reduction of CO

2

and the adhesion of the

flame to the air diffuser disc improves.

(Setting advisable for ignitions at low temperatures).

Turn to the left: (sign

–

), in order to reduce the volume

of air entering the combustion chamber and thus increasing its pressure. The CO

2

improves and

the adhesion of the flame to the diffuser tends to reduce. (This setting is not advisable for ignitions

at low temperatures).

In any case do not bring the combustion head setting more than one point away from that indicated

in the schedule. One set-point corresponds to 3 turns of the rod; a hole (3, fig. 6) at its end facili-

tates counting the number of turns.

AIR DAMPER ADJUSTMENT

, (see fig. 7)

The mobile air damper (A) operated by the jack (B) as-

sures the complete opening of the air intake.

The regulation of the air-rate is made by adjusting the

fixed air damper (C), after loosing the screws (D).

When the optimal regulation is reached, screw tight the

screws (D) to assure a free movement of the mobile air

damper (A).

The settings indicated in the schedule refer to the burner

with its metal cover fitted and the combustion chamber

with “zero” depression.

These regulations are purely indicative.

Each installation however, has its own unpredictable

working conditions: actual nozzle output; positive or neg-

ative pressure in the combustion-chamber, the need of

excess air, etc.

All these conditions may require a different air-damper

setting.

It is important to take account of the fact that the air output of the fan differs according to

whether the burner has its metal cover fitted or not.

Therefore we recommended to proceed as follows:

– adjust the air damper as indicated in the table;

– mount the cover, simply by means of the upper screw;

– check smoke number;

– should it become necessary to modify the air output, remove the cover by loosening the screw,

adjust the air damper, remount the cover and finally recheck the smoke number.

1

2

3

6

D5323

Fig. 6

D

C

D5786

D

A

B

Fig. 7

4