1

20013744

GB

TECHNICAL DATA

BURNER DESCRIPTION

BURNER EQUIPMENT

Flexible pipes with nipples. . . . . . . . . . . N. 2

Screws and nuts for flange. . . . . . . . . . . . . . N. 4

Screw with two nuts for flange. . . . . . . . N. 1

Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N. 1

Insulating gasket . . . . . . . . . . . . . . . . . . N. 3

TYPE

447T2

Thermal power – output

26 / 35.5 ÷ 66.4 kW

–

2.2 / 3 ÷ 5.6 kg/h

Fuel

Gas oil, max. viscosity at 20 °C: 6 mm2/s (1.5° E)

Electrical supply

Single phase, 230 V ± 10% ~ 50Hz

Motor

Run current 0.75 A

–

2850 rpm – 298 rad/s

Capacitor

4

F

Ignition transformer

Secondary 8 kV

–

16 mA

Pump

Pressure: 7 ÷ 15 bar

Absorbed electrical power

0.185 kW

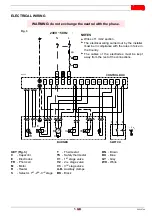

D8390

3

4

6

8

1

2

7

5

1

2

3

9

10

Fig. 1

1

– Return line

2

– Suction line

3

– Gauge connection

4

– Pressure regulator, 2

nd

- 3

rd

stage

5

– Vacuum gauge connection

6

– Hydraulic jacks with air-damper

7

– Combustion head adjustment screw

8

– Lock-out lamp and reset button

9

– Regulation pressure, 1

st

stage

10

– Selector, 1

st

- 2

nd

- 3

rd

stage