9

2915907

GB

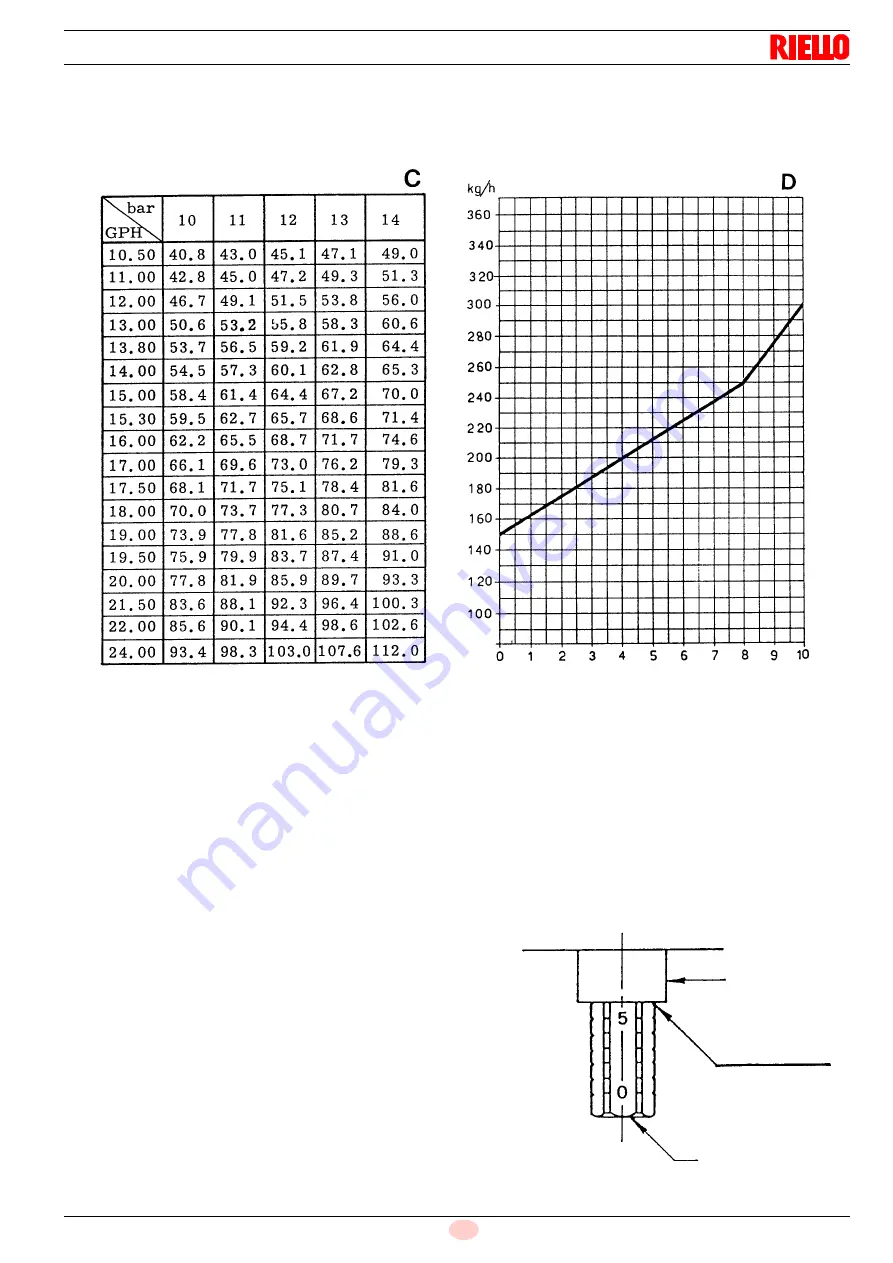

Rated nozzles delivery are shown in the table.

The real nozzle delivery may vary from the rated one up to ± 5%, its detection is made by weighing the oil sprayed out

from the nozzle inserted in a tube.

The pump leaves the factory rated at 12 bar.

Pay attention to not overcome the pump pressure values of 10 and 14 bar.

•

At the end, on the base of the maximum output, you obtain the combustion head adjustment from the diagram D.

The adjustment should be made by turning the screws A till the

set-point (see diagram) is on the line with the washer B.

Nozzles delivery

Pump pressure

Combustion head adjustment

Maximum output

Combustion head adjustment

(set-point)

B

A

Set-point 6

Summary of Contents for P 300 T/G

Page 2: ......