6195

1

GB

INDEX

1.

BURNER DESCRIPTION

Two stage heavy oil burner.

1.1

EQUIPMENT

Flexible tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 2

Nipples . . . . . . . . . . . . . . . . . . . . . . . No. 2

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .No. 2

Screws . . . . . . . . . . . . . . . . . . . . . . . . . No. 4

Flange shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .No. 1

Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . No. 2

Guide extensions (for the lengthened head version).No. 2

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . No. 1

Fitting for operation with emulsified

fuel oil (see page 10) . . . . . . . . . . . . . . . . . . . . . . . No. 1

1.

BURNER DESCRIPTION . . . . . . . . . . . . . . 1

1.1

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.

TECHNICAL DATA . . . . . . . . . . . . . . . . . . 2

2.1

Electrical data . . . . . . . . . . . . . . . . . . . . . . 2

2.2

Dimensions . . . . . . . . . . . . . . . . . . . . . . . 3

2.3

Field of operation . . . . . . . . . . . . . . . . . . . . 3

3.

INSTALLATION . . . . . . . . . . . . . . . . . . . . . 4

3.1

Fuel oil supply systems . . . . . . . . . . . . . . . . 4

3.2

Electrical system . . . . . . . . . . . . . . . . . . . . 5

3.3

Electrical connections . . . . . . . . . . . . . . . . 6

4.

OPERATION . . . . . . . . . . . . . . . . . . . . . . . 7

4.1

Choice of nozzles . . . . . . . . . . . . . . . . . . . 7

4.2

Pump pressure . . . . . . . . . . . . . . . . . . . . . 7

4.3

Combustion head setting . . . . . . . . . . . . . . . 7

4.4

Adjustment of the air damper motor . . . . . . . 7

4.5

Air pressure switch . . . . . . . . . . . . . . . . . . . . 8

4.6

Atomisation temperature adjustment . . . . . . . 8

4.7

Start-up programme . . . . . . . . . . . . . . . . . . . 9

4.8

Ecological oil burners . . . . . . . . . . . . . . . . . 10

4.9

Emulsified fuel oil functioning . . . . . . . . . . . 10

4.10 Start-up programme diagnostics . . . . . . . . . 10

4.11 Operating fault diagnostics . . . . . . . . . . . . . 11

2895

O

The burner meets protection level IP 40, EN 60529.

O

Burner with CE marking in conformity with EEC directives: EMC 2004/108/EEC, Low Voltage

2006/95EEC and Machines 2006/42/EEC.

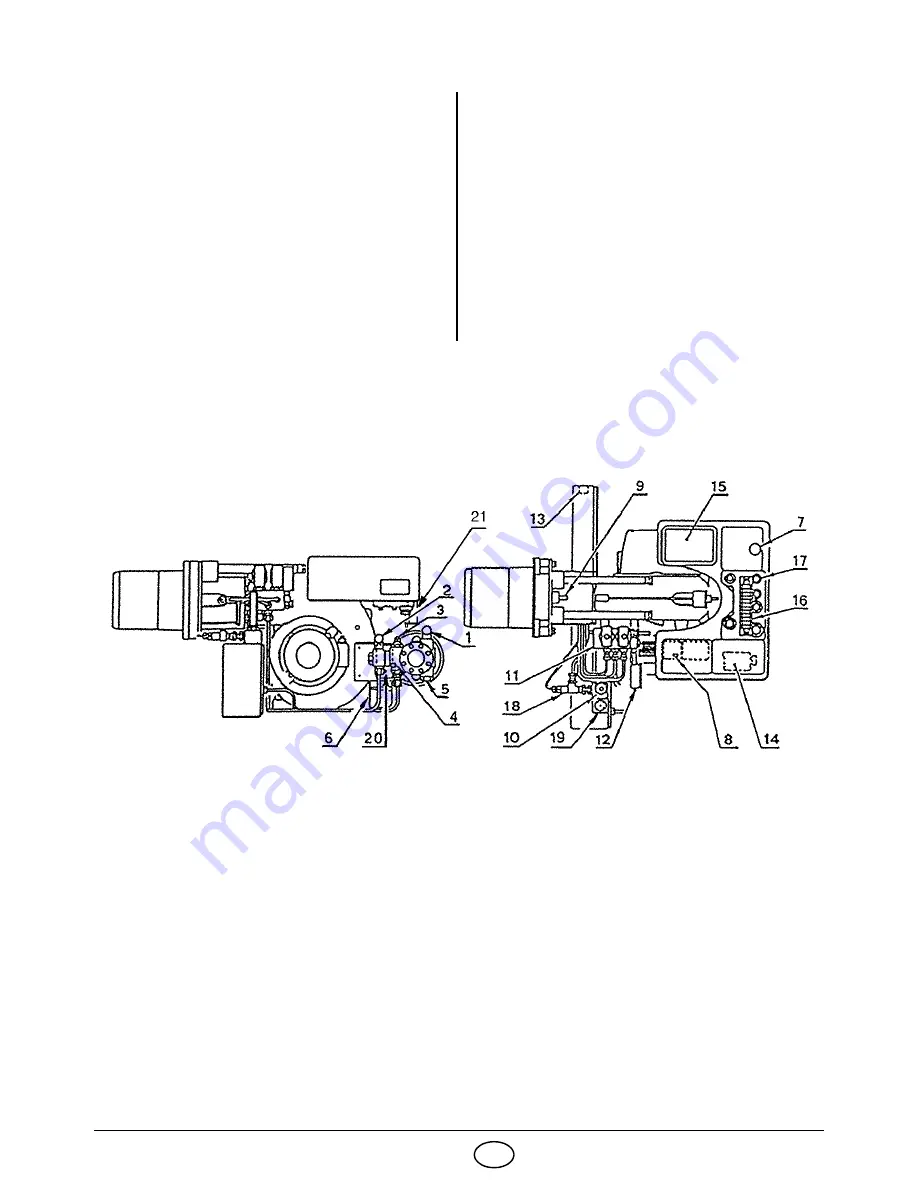

1

- Suction line

2

- Return fitting

3

- Pump pressure adjustment

4

- Manometer fitting (G1/8)

5

- Vacuometer fitting (G1/2)

6

- Air damper opening motor

7

- Control box reset push-button and

lock-out indicator

8

- Fan overload cutout reset

9

- Regulating screw for combustion head

10

- Double filter

11

- Valve assembly

12

- Manometer with protection valve

13

- Adjustment thermostat

14

- Preheater contact maker

15

- Transformer

16

- Terminal strip

17

- Cable glams

18

- Antigas valve

19

- Thermometer

20

- Pump motor starter with reset

21

- Air pressure switch

Fig. 1