6192

1

GB

INDEX

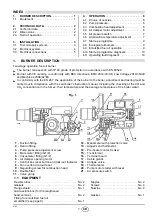

1.

BURNER DESCRIPTION

Two-stage operation fuel-oil burner.

1.

BURNER DESCRIPTION . . . . . . . . . . . . . . 1

1.1

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.

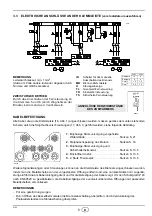

TECHNICAL DATA . . . . . . . . . . . . . . . . . . 2

2.1

Technical data . . . . . . . . . . . . . . . . . . . . . . 2

2.2

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3

Field of operation . . . . . . . . . . . . . . . . . . . . 2

3.

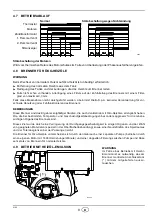

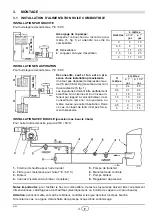

INSTALLATION . . . . . . . . . . . . . . . . . . . . . 3

3.1

Fuel oil supply systems . . . . . . . . . . . . . . . . 3

3.2

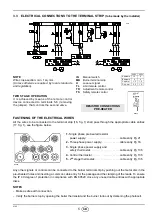

Electrical system . . . . . . . . . . . . . . . . . . . . 4

3.3

Electrical connections . . . . . . . . . . . . . . . . 5

4.

OPERATION . . . . . . . . . . . . . . . . . . . . . . . 6

4.1

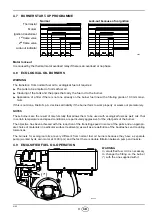

Choice of nozzles . . . . . . . . . . . . . . . . . . . 6

4.2

Pump pressure . . . . . . . . . . . . . . . . . . . . . 6

4.3

Combustion head adjustment . . . . . . . . . . . . 6

4.4

Air damper motor adjustment . . . . . . . . . . . . 6

4.5

Air pressure switch . . . . . . . . . . . . . . . . . . . . . .7

4.6

Atomisation temperature adjustment . . . . . . . 7

4.7

Start-up programme. . . . . . . . . . . . . . . . . . . . 9

4.8

Ecological oil burners . . . . . . . . . . . . . . . . . . 9

4.9

Emulsified fuel oil operation . . . . . . . . . . . . . 9

4.10 Start-up programme diagnostic . . . . . . . . . . 10

4.11 Operating fault diagnostic . . . . . . . . . . . . . . 10

2893

The burner corresponds with IP 40 grade of protection in accordance with EN 60529.

Burner with CE marking in conformity with EEC directives: EMC 2014/30/UE, Low Voltage 2014/35/UE

and Machines 2006/42/EC.

In conformity with the EN 267, the application of the burner to the boiler, adjustment and testing must be

carried out in compliance with the said boiler's instruction manual, including the checking of the CO and

CO

2

concentration in the fumes, their temperature and the average temperature of the boiler water.

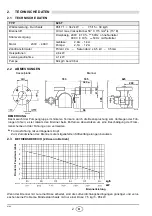

1

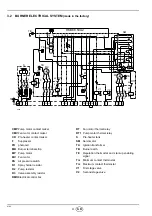

- Suction fitting

2

- Return fitting

3

- Pump pressure adjustment screw

4

- Manometer fitting (G1/8)

5

- Vacuometer fitting (G1/2)

6

- Air damper opening motor

7

- Control box reset button and lock-out indicator

8

- Fan overload cutout reset

9

- Regulating screw for combustion head

10

- Double filter

11

- Valve group

12

- Manometer with protection valve

13

- Adjustment thermostat

14

- Pre-heater contact maker

15

- Transformer

16

- Terminal board

17

- Cable glands

18

- Antigas valve

19

- Thermometer

20

- Pump motor starter with reset

21

- Air pressure switch

Fig. 1

1.1

EQUIPMENT

Flexible tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 2

Nipples . . . . . . . . . . . . . . . . . . . . . . . No. 2

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 2

Screws. . . . . . . . . . . . . . . . . . . . . . . . . . No. 4

Flange shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 1

Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . No. 2

Guide extensions (for the lengthened

head version). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . No. 2

Gasket. . . . . . . . . . . . . . . . . . . . . . . . . . No. 1

Fitting for emulsified fuel oil

emulsified (see page 9) . . . . . . . . . . . . . . . . . . . . . No. 1