6192

3

GB

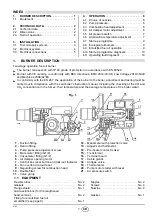

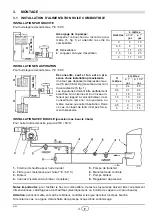

3.

INSTALLATION

3.1

FUEL OIL SUPPLY SYSTEMS

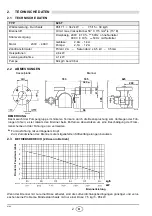

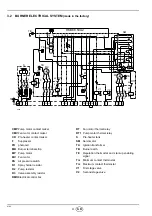

GRAVITY SYSTEM

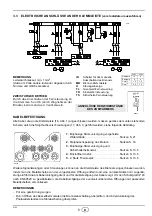

SUCTION SYSTEM

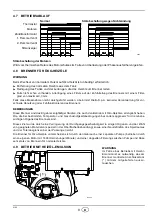

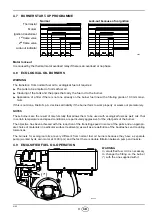

LOOP SYSTEM

(max loop system pressure 3 bar)

H

metres

L metres

Diam.

3/4”

Diam.

1” gas

0

5

10

0.5

8

15

1

11

20

1.5

14

25

2

17

30

Pump priming:

loosen the tap from the vacuometer fitting

(5, fig. 1) and wait for the fuel to flow out.

H

: Difference in height

L

: Length of the suction tube

For light oil with max. viscosity 7°E at 50°C.

D2720

max. 30m

H

H

metres

L metres

diam.

1” gas

diam. 1

1/4”

0

24

45

0.5

21

40

1

18

35

1.5

15

30

2

12

25

2.5

9

20

3

6

15

Not advised. To be used only in case of

previously existing system

.

Never exceed the max. vaccum of 0.5 bar

(38 cm Hg) measured at the vacuometer

fitting (5, fig. 1).

The pipes should be perfectly airtight.

When the tank is placed below of the burn-

er level, the return pipe should arrive at the

same level as the suction pipe.

In this case the foot valve is not required.

For light oil with max viscosity 7°E at 50°C.

D2721

max. 30m

H

H

1

- Tank (heated for heavy oil)

5

- Transfer pump

2

- Filter (with resistor for oil > 7°E / 50°C)

6

- Control manometer

3

- Burner

7

- Burner pump

4

- Burner cut-out gate valves (coupled)

8

- Pressure adjuster

For heavy oil with viscosity up to 20°E / 50°C.

Important note

: to allow the fuel to flow properly, all the pipes have to be properly sized, insulated and heat-

ed (electrically or by means of steam or hot water).

Warning

: before using the burner, make sure that there is no obstruction in the return pipe,

any obstruction may damage the sealing of the pump.

D2631