6192

6

GB

4.

OPERATION

4.1

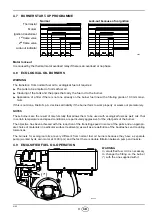

CHOICE OF NOZZLES

Recommended nozzles:

- Monarch F 80 H0.

4.2

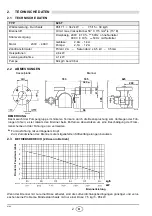

PUMP PRESSURE

Recommended pressure:

- Fluid oil: 20 bar

- Heavy oil: 25 bar

Rated deliveries of the nozzles are indicated on the above

list and refer to a light oil (viscosity from 3 to 5°E at 50° C pre-

heated at 100°C). The actual flow rate may vary by ± 5%

compared with the rated flow rate.

In values in between those indicated in the tables are

required, the pump pressure could be changed or the

composition of the nozzles varied.

The pump leaves the factory set at 20 bar.

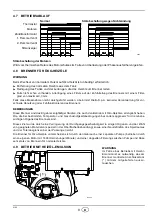

4.3

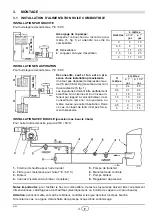

COMBUSTION HEAD ADJUSTMENT

Turn the screw

A,

fig. 2

till the set-point, detected from the dia-

gram, is in the line with the washer

B,

fig. 2.

4.4

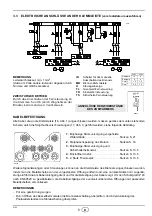

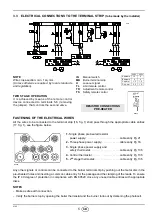

ADJUSTMENT OF THE AIR DAMPER MOTOR

STOP - Blue lever

This lever leaves the factory vertically positioned and corre-

sponds to the air damper fully closed.

A partial opening of the air damper might be obtained by

moving this lever leftwards (

+

on the plate).

The new position of the air damper is detectable when the

burner stops.

Do not exceed the position of the orange lever for the

1

st

stage.

1

st

STAGE - Orange lever

The orange lever controls the air damper position for the first

flame, it is adjustable both for opening and closing.

2

nd

STAGE - Red and black levers

The red lever controls the air damper position for the second

flame, it is adjustable both on closing and opening.

The black lever controls the opening of the second oil valve

and it must always be slightly before the red lever, but never

the first stage orange one.

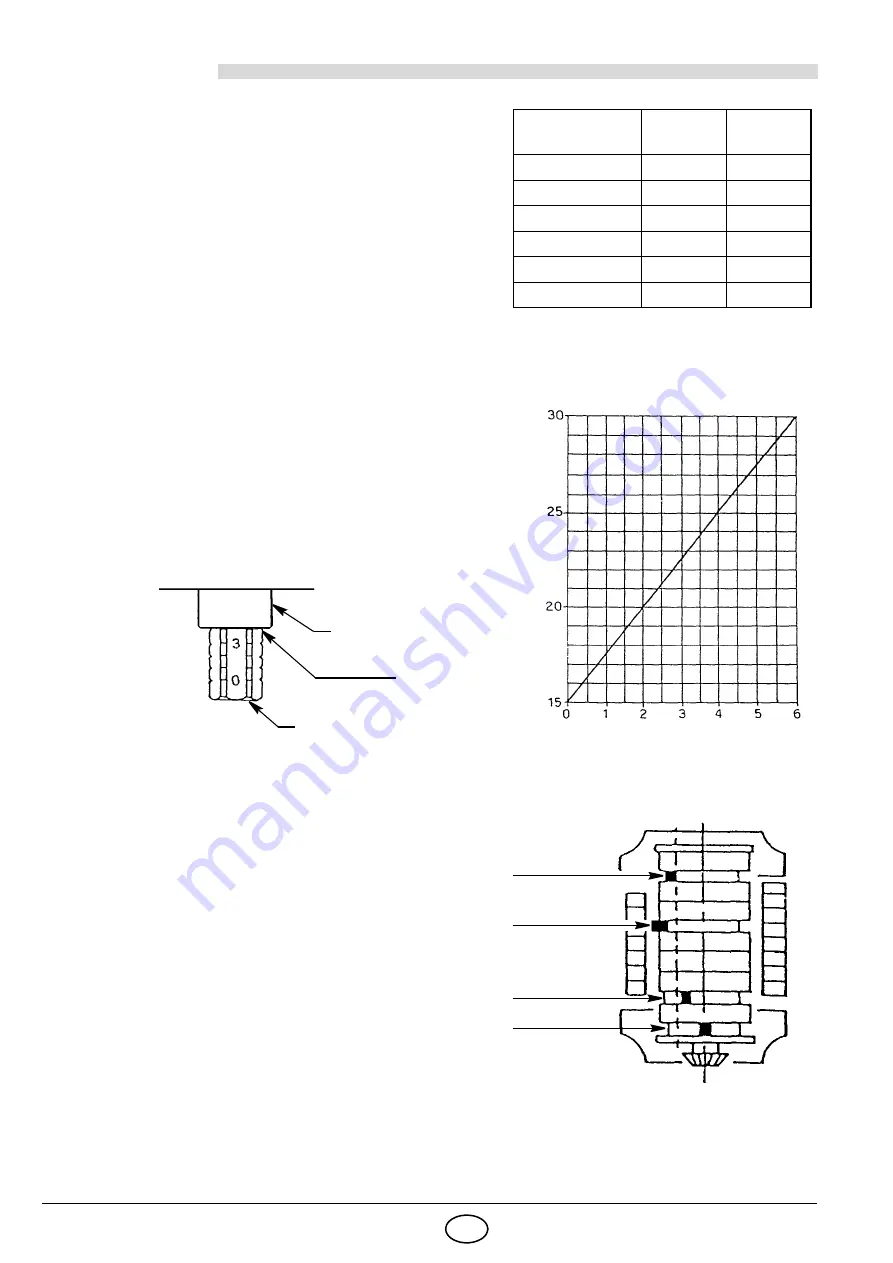

Nozzle

GPH (45° - 60°)

20 bar

kg/h

25 bar

kg/h

1.25 + 1.25

15.00

17.00

1.50 + 1.50

18.00

20.30

1.75 + 1.75

21.00

23.80

2.00 + 2.00

24.00

27.10

2.25 + 2.25

27.00

30.50

2.50 + 2.50

30.00

–

D2638

Black lever

Red lever

Orange lever

Blue lever

Opening

+

–

Closing

kg/h

Set-points

D2636

D2637

B

Set-point 4

A

Fig. 2