6192

10

GB

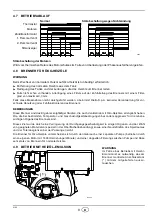

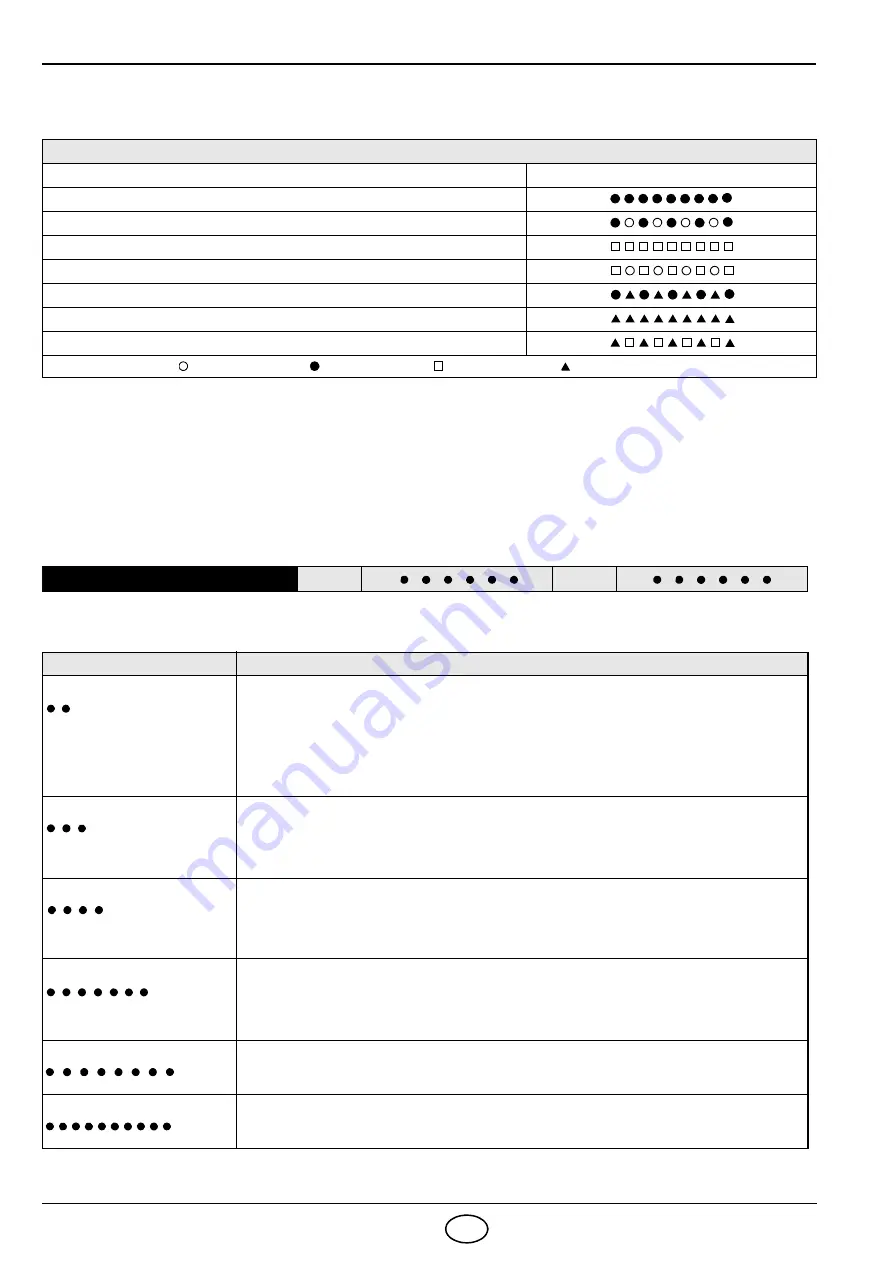

4.10 START-UP PROGRAMME DIAGNOSTIC

During the start-up programme, the indications are shown in the following table:

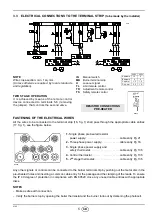

4.11 OPERATING FAULT DIAGNOSTIC

The control box has a self-diagnostic system by which it it is possible to simply identify the possible causes

of malfunctioning (signal

RED LED

).

To use this function, wait at least ten seconds from the moment the control box is placed in safety mode,

and then press the reset button for a minimum of 3 seconds.

After releasing the button, the RED LED starts flashing as shown in the diagram below.

The pulses of the LED constitute a signalwith intervals of approximately three seconds.

The number of pulses will provide the information on the possible faults, as per the table below:

COLOUR CODE TABLE

Sequences

Colour code

Preventilation

Ignition phase

Operation with flame ok

Operation with weak flame

Electrical supply lower than

~

170V

Lock-out

Extraneous light

Key:

Off

Yellow

Green

Red

SIGNAL

PROBABLE CAUSE

2 blinks

No stable flame is detected in the safety time:

– photocell fault;

– oil valve fault;

– neutral/phase reversal;

– faulty ignition transformer

– poor burner regulation (insufficient fuel oil).

3 blinks

Min. air pressure switch (if installed) does not close:

– air pressure switch faulty;

– air pressure switch not regulated;

– max. air pressure switch triggered (if installed).

4 blinks

Min. air pressure switch (if installed) does not open or light in the chamber before

ignition:

– air pressure switch faulty;

– air pressure switch not regulated.

7 blinks

Loss of flame during operation:

– burner not regulated (insufficient fuel oil);

– oil valve fault;

– short circuit between photocell and earth.

8 blinks

– Faulty thermostat for oil permissive signal;

– Heating resistances blown.

10 blinks

– Wiring error or internal fault.

RED LED on

wait at least 10 s

press the button

for > 3 secs.

signal

signal

Interval

3 secs