17

20184179

GB

Installation

6.10

Nozzle installation

The burner complies with the emission requirements of the EN

267 standard. In order to guarantee that emissions do not vary,

recommended and/or alternative nozzles specified by Riello in

the Instruction and warning booklet should be used.

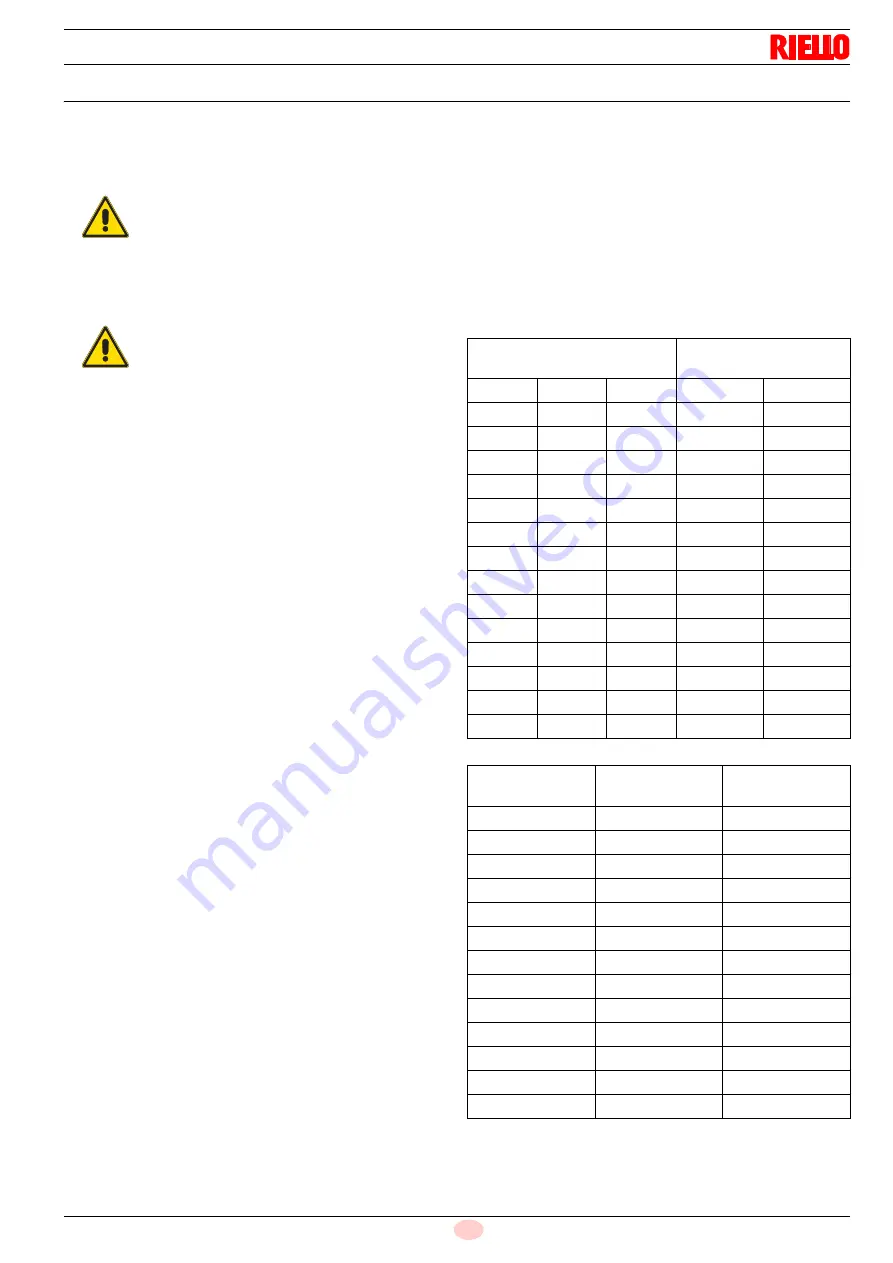

6.10.1 Nozzle selection

First of all state the maximum output required with all three

nozzles in operation.

On the base of the maximum output choose, from Tab. G, three

related nozzles.

Nozzles: 60° - Pump pressure: 25 bar

The references of Tab. H should be followed in case of need of:

–

modification of the pump pressure in order to vary the output,

–

different composition of the 3 nozzles group,

–

knowledge of the output in 1st and 2nd stage.

AVAILABLE NOZZLES

Tab. G

Tab. H

ATTENTION

It is advisable to replace the nozzle once a year

during periodical maintenance.

CAUTION

The use of nozzles other than those specified by

Riello S.p.A. and inadequate regular maintenance

may result into emission limits non-conforming to

the values set forth by the regulations in force, and

in extremely serious cases, into potential hazards

to people and objects.

The manufacturing Company shall not be liable

for any such damage arising from non-

observance of the requirements contained in this

manual.

Nozzle

GPH 60°

Total Output

kg/h 1°+2°+3°

1°

2°

3°

25 bar

28 bar

11,00

11,00

11,00

207

291

12,00

12,00

12,00

228

240

13,00

13,00

13,00

246

261

13,80

13,80

13,80

258

279

14,00

14,00

14,00

264

282

15,00

15,00

15,00

285

300

15,30

15,30

15,30

291

306

16,00

16,00

16,00

300

321

17,00

17,00

17,00

321

342

18,00

18,00

18,00

339

363

19,00

19,00

19,00

357

384

20,00

20,00

20,00

378

405

21,50

21,50

21,50

405

432

24,00

24,00

24,00

453

–

GPH

25 bar

kg/h

28 bar

kg/h

12,00

76

80

13,00

82

87

13,80

86

93

14,00

88

94

15,00

95

100

15,30

97

102

16,00

100

107

17,00

107

114

18,00

113

121

19,00

119

128

20,00

126

135

21,50

135

144

24,00

151

–

Summary of Contents for PRESS 450 T/N

Page 2: ...Translation of the original instructions ...

Page 35: ...33 20170392 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 36: ...20170392 34 GB Appendix Electrical panel layout ...

Page 37: ...35 20170392 GB Appendix Electrical panel layout 0 1 0 2 3 2 3 ...

Page 38: ...20170392 36 GB Appendix Electrical panel layout 0 0 ...

Page 41: ......

Page 42: ......

Page 43: ......