20184179

18

GB

Installation

6.11

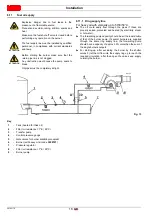

Fuel oil supply

6.11.1 Ring supply line

For heavy oil with viscosity up to 50°E/50°C.

The oil could easily flow through the pipes if those are

properly seized, protected and heated (by electricity, steam

or hot water).

The forwarding pump capacity should be all the least double

of that of the burner pump. If several burners are supplied

through the same ring supply line, the forwarding pump

should have a capacity of approx. 30% more than the sum of

the single burners outputs.

For starting-up: after excluding the burner by the shutter

valves 5) let the oil flow into the supply ring up to reach the

required circulation; after than open the valves and supply

normally the burner.

Key

Explosion danger due to fuel leaks in the

presence of a flammable source.

Precautions: avoid knocking, attrition, sparks and

heat.

Make sure the fuel shut-off valve is closed before

performing any operation on the burner.

ATTENTION

The fuel supply line must be installed by qualified

personnel, in compliance with current standards

and laws.

ATTENTION

Before starting the burner make sure that the

return pipe line is not clogged.

Any obstruction would cause the pump seals to

break.

Oil pipes must be completely airtight.

Fig. 13

D2734

1

-

Tank (heated for thick oil)

2

-

Filter (oil resistance > 7°E / 50°C)

3

-

Transfer pump

4

-

Control pressure gauge

5

-

Gate valves for burner disabling (coupled)

6

-

Burner (with heavy oil kit code

3000721

)

7

-

Pressure regulator

8

-

Filter (oil resistance > 7°E / 50°C)

9

-

Burner pump

Summary of Contents for PRESS 450 T/N

Page 2: ...Translation of the original instructions ...

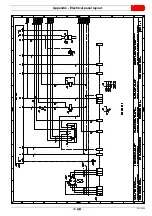

Page 35: ...33 20170392 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 36: ...20170392 34 GB Appendix Electrical panel layout ...

Page 37: ...35 20170392 GB Appendix Electrical panel layout 0 1 0 2 3 2 3 ...

Page 38: ...20170392 36 GB Appendix Electrical panel layout 0 0 ...

Page 41: ......

Page 42: ......

Page 43: ......