27

20063165

GB

Maintenance

7.1

Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking oper-

ations:

7.2

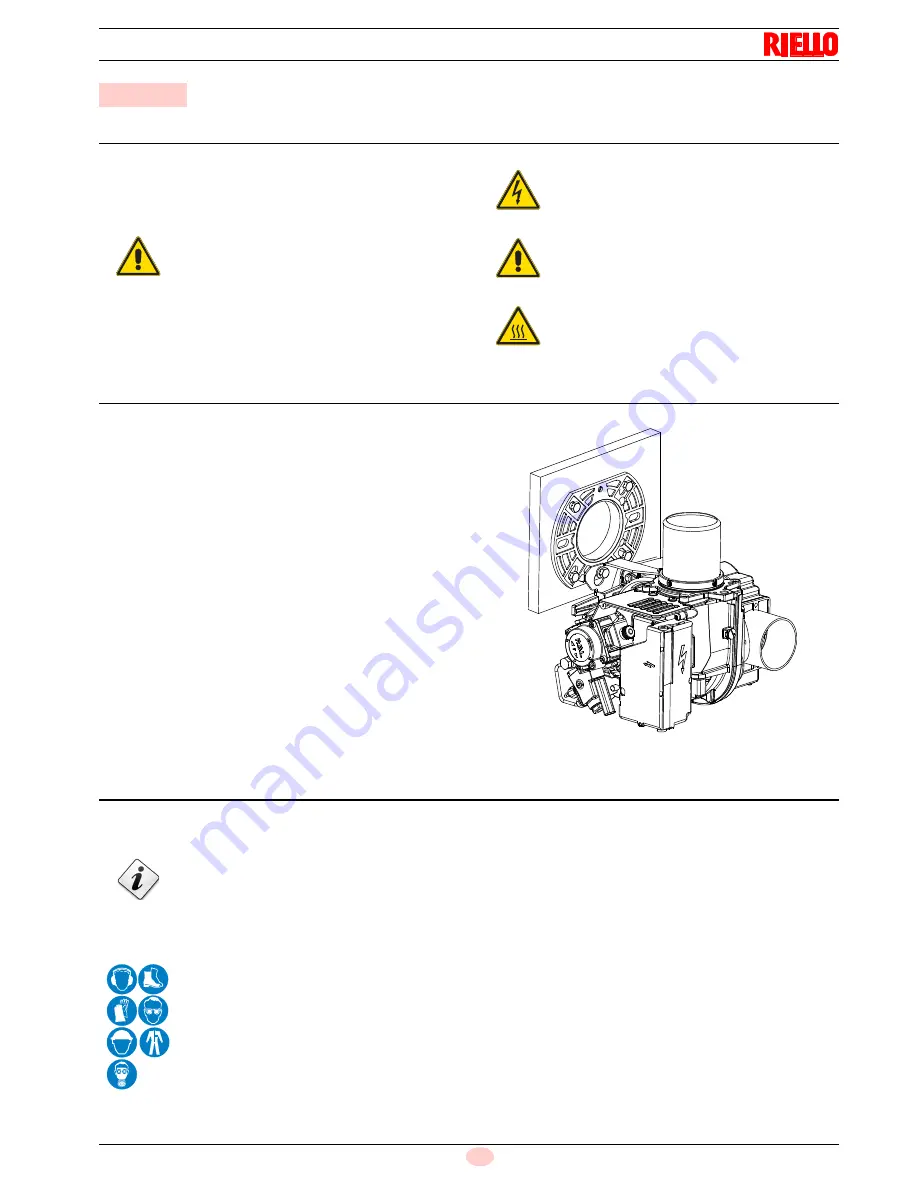

Burner maintenance position

To facilitate maintenance, position the burner as shown in

Fig. 25.

7.3

Maintenance programme

7.3.1

Maintenance frequency

7.3.2

Checking and cleaning

Burner

Clean the outside of the burner.

Combustion

Perform an analysis of combustion gases.

Significant differences compared to the previous test indicate the

points where the maintenance operation will need to be more

thorough.

Boiler

Clean the boiler according to the instruction booklet, so as to be

able to find the original combustion data, in particular; pressure in

the combustion chamber and flue gas temperatures.

7

Maintenance

DANGER

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the con-

tents of this manual and in compliance with the

standards and regulations of current laws.

DANGER

Disconnect the electrical supply from the burner

by means of the main system switch.

DANGER

Close the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

Fig. 25

20066296

The gas combustion system should be checked at

least once a year by a representative of the man-

ufacturer or another specialised technician.

The operator must use the required equipment

during maintenance.