6

OIL PUMP

If the burner goes to a lockout state due to a lack of oil pressure, the pump may require priming. Remove

the pressure gauge bleed port plug until oil is seen to be present and replace the plug.

Single-pipe systems

Where the lowermost part of the tank is above the level of the oil pump, a single-pipe gravity system can

be used. The supply pipe should be connected to the suction port on the burner pump via the flexible hose

(supplied). The pump is pre-set to run on single-pipe oil supplies the bypass screw (

3

) must not be present

in the return line (see

fig 4

).

Two-pipe systems

Where the lowermost part of the tank is below the level of the burner, a two-pipe suction lift is necessary. A

second flexible hose will be required, and the oil pump must first be converted for use. Remove the return

line plug (

2

), insert the bypass screw (

3

) and connect a second flexible oil line (not supplied).

Single pipe oil supplies with a de-aerator

Where a two-pipe suction lift is required, but it is not feasible to fit a return pipe, an oil de-aerator can be

used. The burner should be piped and the pump converted as for a two-pipe system, up to the de-aerator,

at which point a single pipe can be taken to the storage tank. The de-aerator should be fitted as close to

the boiler as possible though externally to the premises at a height no lower than the oil pump.

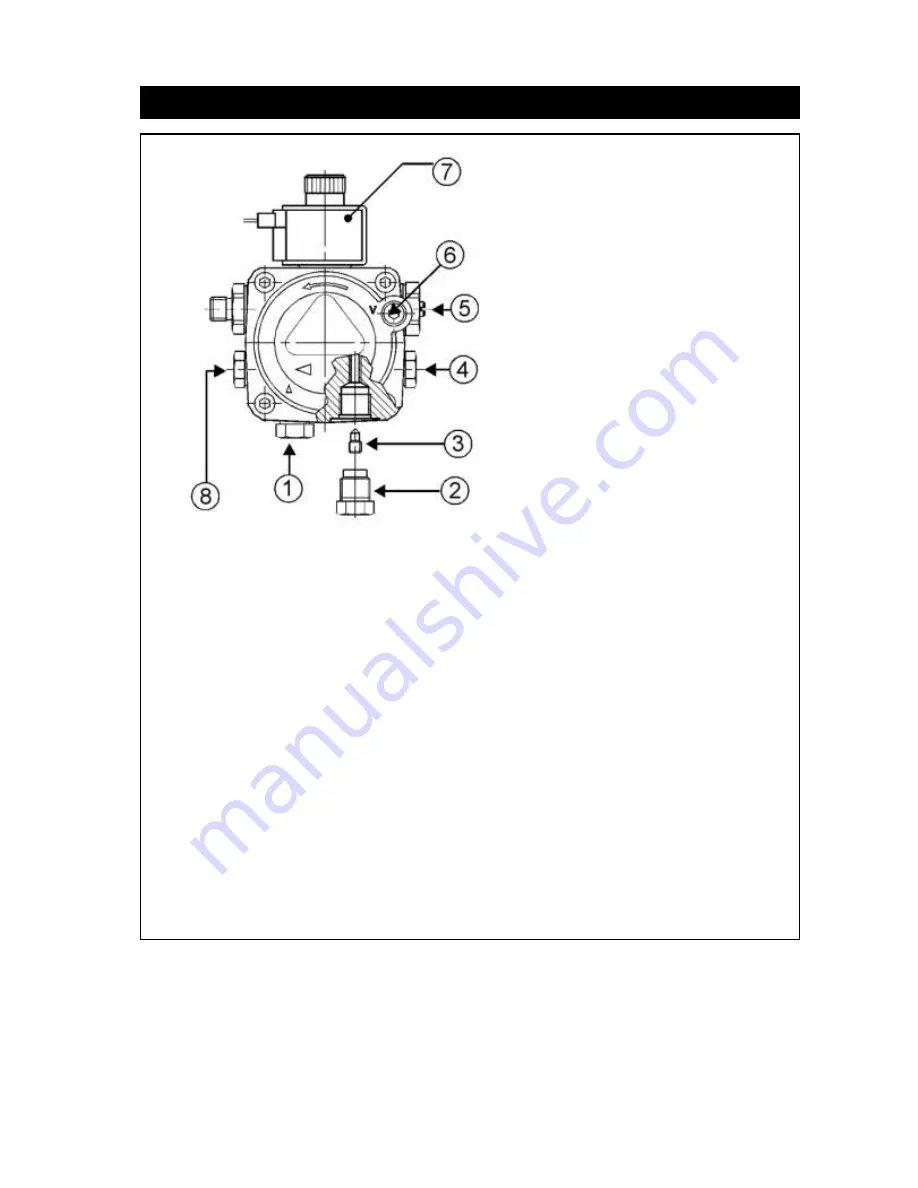

Fig 4

1

– Suction line

2

– Return line

3

– Bypass screw

4

– Pressure gauge connection /

air bleed point

5

– Pressure adjustment

6

– Suction gauge connection

7

– Solenoid valve

8

– Auxiliary pressure test point

Summary of Contents for RDB3

Page 11: ...11 Fig 11 Burner Fault finding Logic Chart ...

Page 13: ...13 Fig 12 ...