2862

1

GB

INDEX

1.

BURNER DESCRIPTION

One stage light oil burner.

1.1

BURNER EQUIPMENT

Flange with insulating gasket . . . .No. 1

Screw and nuts for flange to be fixed to the heat generator . No. 4

Screw and nuts for flange . . . . . .No. 1

Flexible oil pipes with nipples . . . . . . . . . . . . . . . . . . . . No. 2

7 pin plug . . . . . . . . . . . . . . . . . . .No. 1

1.

BURNER DESCRIPTION . . . . . . . . . . . .

1

1.1 Burner equipment . . . . . . . . . . . . . . . . .

1

2.

TECHNICAL DATA . . . . . . . . . . . . . . . . . 2

2.1 Technical data . . . . . . . . . . . . . . . . . . . .

2

2.2 Accessories . . . . . . . . . . . . . . . . . . . . . .

2

2.3 Overall dimensions . . . . . . . . . . . . . . . .

3

2.4 Firing rate . . . . . . . . . . . . . . . . . . . . . . . .

3

3.

INSTALLATION . . . . . . . . . . . . . . . . . . . . 4

3.1 Heat generator fixing . . . . . . . . . . . . . . .

4

3.2 Working position . . . . . . . . . . . . . . . . . .

4

3.3 Fuel supply . . . . . . . . . . . . . . . . . . . . . .

5

3.4 Hydraulic systems . . . . . . . . . . . . . . . . .

5

3.5 Electrical wiring . . . . . . . . . . . . . . . . . . .

7

4.

WORKING . . . . . . . . . . . . . . . . . . . . . . .

8

4.1 Combustion adjustment. . . . . . . . . . . . . .

8

4.2 Recommended nozzles . . . . . . . . . . . . . .

8

4.3 Electrodes adjustment. . . . . . . . . . . . . . .

9

4.4 Pump pressure . . . . . . . . . . . . . . . . . . . .

9

4.5 Combustion head setting. . . . . . . . . . . . .

9

4.6 Air damper adjustment . . . . . . . . . . . . . .

9

4.7 Burner start-up cycle . . . . . . . . . . . . . . . . 10

5.

MAINTENANCE . . . . . . . . . . . . . . . . . . . 10

6.

FAULTS / SOLUTIONS . . . . . . . . . . . . . 11

If the burner is to be combined with a hot air generator in Germany (WLE according to DIN 4794), the con-

trol box must be replaced with a Riello 550 SMD control box (remove the bridge), and the flame sensor

must be replaced with the amplified type (both fully interchangeable). This control box, combined with the

“remote reset kit” (which can be ordered separately), means that the burner can be reset by remote control.

ATTENTION

1

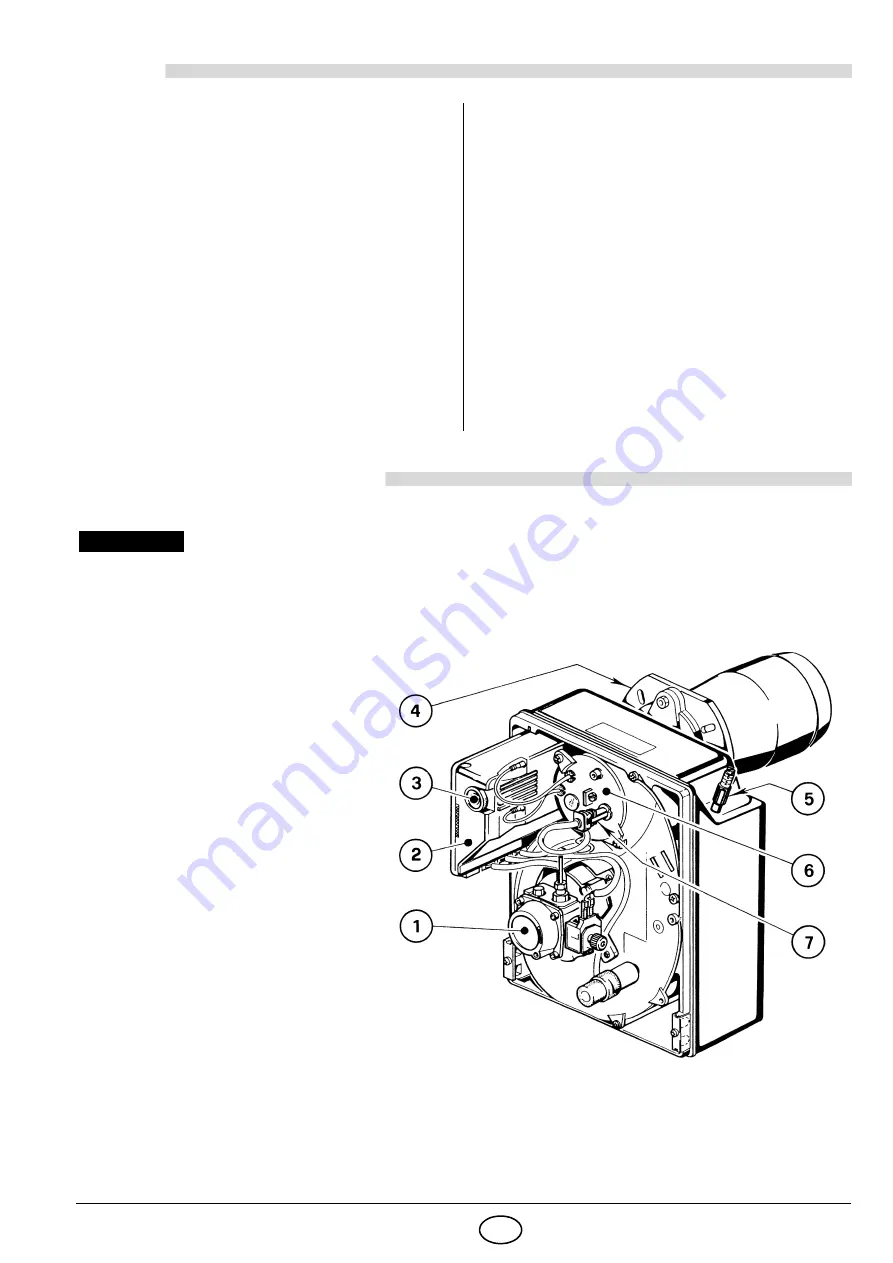

– Pompa olio

2

– Apparecchiatura di

comando e controllo

3

– Pulsante di sblocco con

segnalazione di blocco

4

– Flangia con schermo isolante

5

– Gruppo regolazione

serranda aria

6

– Gruppo portaugello

7

– Fotoresistenza

Fig. 1

S7179