10

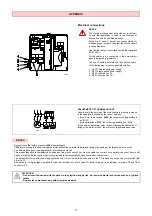

BURNER OPERATION

BURNER STARTING

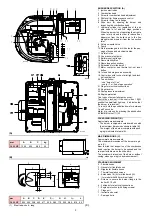

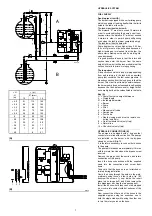

(A) - (B)

Starting phases with progressive time intervals

shown in seconds:

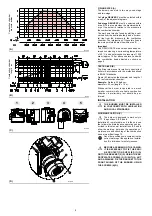

• Control device TL closes.

After about 3s:

•

0 s :

The control box starting cycle begins.

•

2 s :

The fan motor starts.

•

3 s :

The ignition transformer is connected.

The pump 3) sucks the fuel from the tank

through the piping 1) and the filter 2) and

pumps it under pressure to delivery. The pis-

ton 4) rises and the fuel returns to the tank

through the piping 5) - 7). The screw 6) closes

the by-pass heading towards suction and the

solenoid valves 8) - 11) - 16), de-energized,

close the passage to the nozzles.

The hydraulic cylinder 15), piston A, opens the

air gate valve: pre-purging begins with the 1st

stage air delivery.

•

22 s :

Solenoid valves 8) and 16) open and the

fuel passes through the piping 9) and filter 10)

and is then sprayed out through the nozzle,

igniting when it comes into contact with the

spark. This is the 1st stage flame.

•

29 s:

The ignition transformer switches off.

•

36 s:

If the control device TR is closed or has

been replaced by a jumper wire, the 2nd stage

solenoid valve 11) is opened and the fuel

enters the valve 12) and raises the piston

which opens two passages: one to piping 13),

filter 14), and the 2nd stage nozzle, and the

other to the cylinder 15), piston B, that opens

the fan air gate valve in the 2nd stage.

The starting cycle comes to an end.

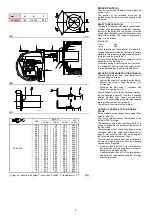

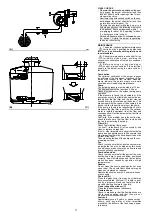

STEADY STATE OPERATION

System equipped with one control device TR

Once the starting cycle has come to an end, the

command of the 2nd stage solenoid valve pass-

es on to the control device TR that controls boiler

temperature or pressure.

• When the temperature or the pressure increas-

es until the control device TR opens, solenoid

valve 11) closes, and the burner passes from

the 2nd to the 1st stage of operation.

• When the temperature or pressure decreases

until the control device TR closes, solenoid

valve 11) opens, and the burner passes from

the 1st to the 2nd stage of operation, and so on.

• The burner stops when the demand for heat is

less than the amount of heat delivered by the

burner in the 1st stage. In this case, the control

device TL opens, and solenoid valves 8)-16)

close, the flame immediately goes out. The

fan's air gate valve closes completely.

Systems not equipped with control device

TR (jumper wire installed)

The burner is fired as described in the case

above. If the temperature or pressure increase

until control device TL opens, the burner shuts

down (Section A-A in the diagram).

When the solenoid valve 11) de-energizes, the

piston 12) closes the passage to the 2nd stage

nozzle and the fuel contained in the cylinder 15),

piston B, is discharged into the return piping 7).

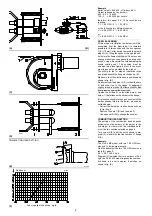

FIRING FAILURE

If the burner does not fire, it goes into lock-out with-

in 5 s of the opening of the 1st nozzle valve and 30

s after the closing of control device TL.

The control box red pilot light will light up.

UNDESIRED SHUTDOWN DURING OPERA-

TION

If the flame goes out during operation, the burner

shuts down automatically within 1 second and

automatically attempts to start again by repeat-

ing the starting cycle.

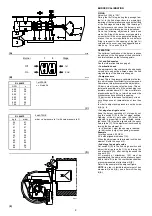

(A)

TL

TR

0

1°

2°

A

A

TL

Off

Yellow

Green

Red

For further details see page 13.

*

D3280

D3281

LED

RMO

*

LED

RMO

*

(B)

D7464