5

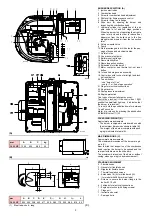

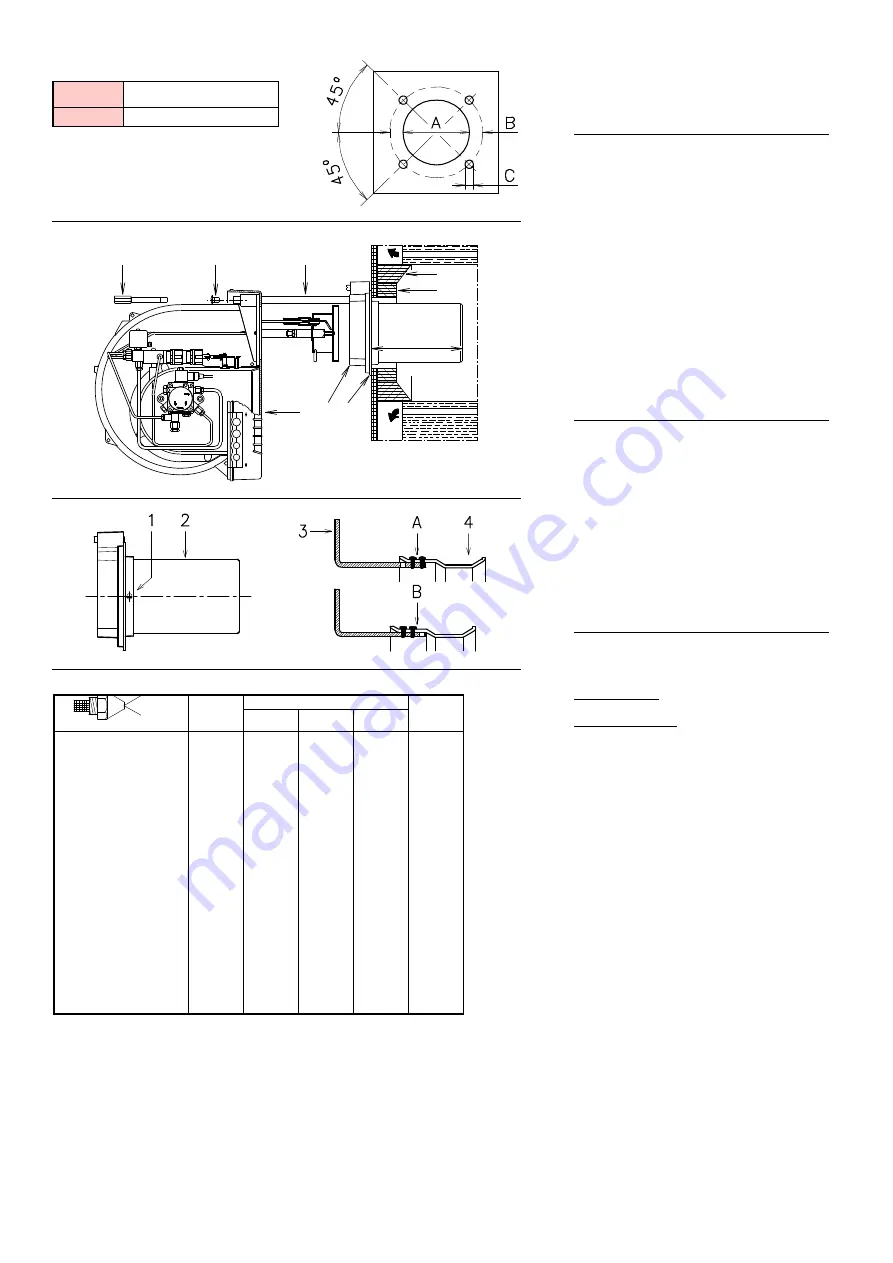

BOILER PLATE (A)

Drill the combustion chamber locking plate as

shown in (A).

The position of the threaded holes can be

marked using the thermal screen supplied with

the burner.

BLAST TUBE LENGTH (B)

The length of the blast tube must be selected ac-

cording to the indications provided by the manu-

facturer of the boiler, and in any case it must be

greater than the thickness of the boiler door com-

plete with its fettling. The range of lengths avail-

able, L, is as follows:

Blast tube 7):

• short

250

• long

385

For boilers with front flue passes 10) or flame in-

version chambers, protective fettling in refractory

material 8) must be inserted between the boiler's

fettling 9) and the blast tube 7).

This protective fettling must not compromise the

extraction of the blast tube.

For boilers having a water-cooled front the refrac-

tory fettling 8)-9)(B) is not required unless it is ex-

pressly requested by the boiler manufacturer.

SECURING THE BURNER TO THE BOILER (B)

Disassemble the blast tube 7) from the burner 4)

by proceeding as follows:

- Remove the screws 2) from the two slide bars 3).

- Remove the screw 1) fixing the burner 4) to

the flange 5).

- Withdraw the blast tube 7) complete with

flange 5) and slide bars 3).

Secure flange 5)(B) to the boiler plate interpos-

ing the supplied gasket 6). Use the 4 supplied

screws provided after having protected the

thread with antiscruffing products (high-temper-

ature grease, compounds, graphite).

The burner-boiler seal must be airtight.

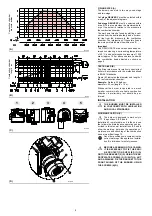

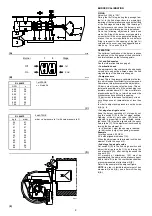

CHOICE OF NOZZLES FOR 1st AND 2nd

STAGE

Both nozzles must be chosen from among those

listed in table (D).

The first nozzle determines the delivery of the

burner in the 1st stage.

The second nozzle works together with the 1st

nozzle to determine the delivery of the burner in

the 2nd stage.

The deliveries of the 1st and 2nd stages must be

contained within the value range indicated on

page 2. Use nozzles with a 60° spray angle at

the recommended pressure of 12 bar

The two nozzles usually have equal deliveries,

but the 1st stage nozzle may have the following

specifications if required:

• a delivery less than 50% of the total delivery

whenever the back-pressure peak must be re-

duced at the moment of firing;

• a delivery higher than 50% of the total delivery

whenever the combustion during the 1st stage

must be improved.

(A)

(B)

(C)

4

L

7

9

8

6

5

1

2

3

1 0

1 0

V

P

mm

A

B

C

RL 64 MZ

185

275-325

M12

(1) light oil: density 0.84 kg/dm

3

- viscosity 4.2 cSt/20 °C

- temperature 10 °C

GPH

kg/h

(1)

kW

12 bar

10 bar

12 bar

14 bar

RL 64 MZ

4.00

4.50

5.00

5.50

6.00

6.50

7.00

7.50

8.00

8.30

8.50

9.00

9.50

10.0

10.5

11.0

12.0

12.3

13.0

13.8

14.0

15.0

15.3

16.0

17.0

15.4

17.3

19.2

21.1

23.1

25.0

26.9

28.8

30.8

31.9

32.7

34.6

36.5

38.4

40.4

42.3

46.1

47.3

50.0

53.1

53.8

57.7

58.8

61.5

65.4

17.0

19.1

21.2

23.3

25.5

27.6

29.7

31.8

33.9

35.2

36.1

38.2

40.3

42.4

44.6

46.7

50.9

52.2

55.1

58.5

59.4

63.6

64.9

67.9

72.1

18.4

20.7

23.1

25.4

27.7

30.0

32.3

34.6

36.9

38.3

39.2

41.5

43.8

46.1

48.4

50.7

55.3

56.7

59.9

63.3

64.5

69.2

70.5

73.8

78.4

201.6

226.5

251.4

276.3

302.4

327.3

352.3

377.2

402.1

417.5

428.2

453.1

478.0

502.9

529.0

553.9

603.7

619.1

653.5

693.8

704.5

754.3

769.7

805.3

855.1

60

D455

D457

D7462

(D)