Installation

17

20045163

GB

4.5

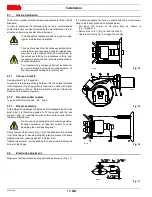

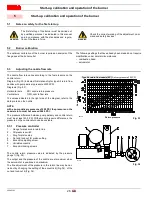

Combustion head pre-setting

Disassemble the blast tube 9) from the burner 6) by proceeding as

follows:

– loosen the four screws 3) and remove the cover 1);

– remove the screws 2) from the two slide bars 5);

– remove the two screws 4) fixing the burner 6) to the flange 7);

– withdraw the blast tube 9) complete with flange 7) and slide

bars 5).

At this point check, whether the maximum delivery of the burner is

contained in area B or in area C of the firing rate. See Fig. 5.

If it is in area B then no operation is required.

If, on the other hand, it is in area C:

– unscrew the screws 1)(Fig. 11) and disassemble the blast

tube 5);

– unscrew the screws 3) and remove the shutter 4);

– tighten the screws 3) on the rod 2).

Now refit the blast tube 5) and the screws 1).

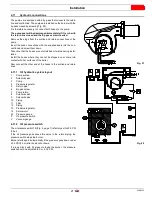

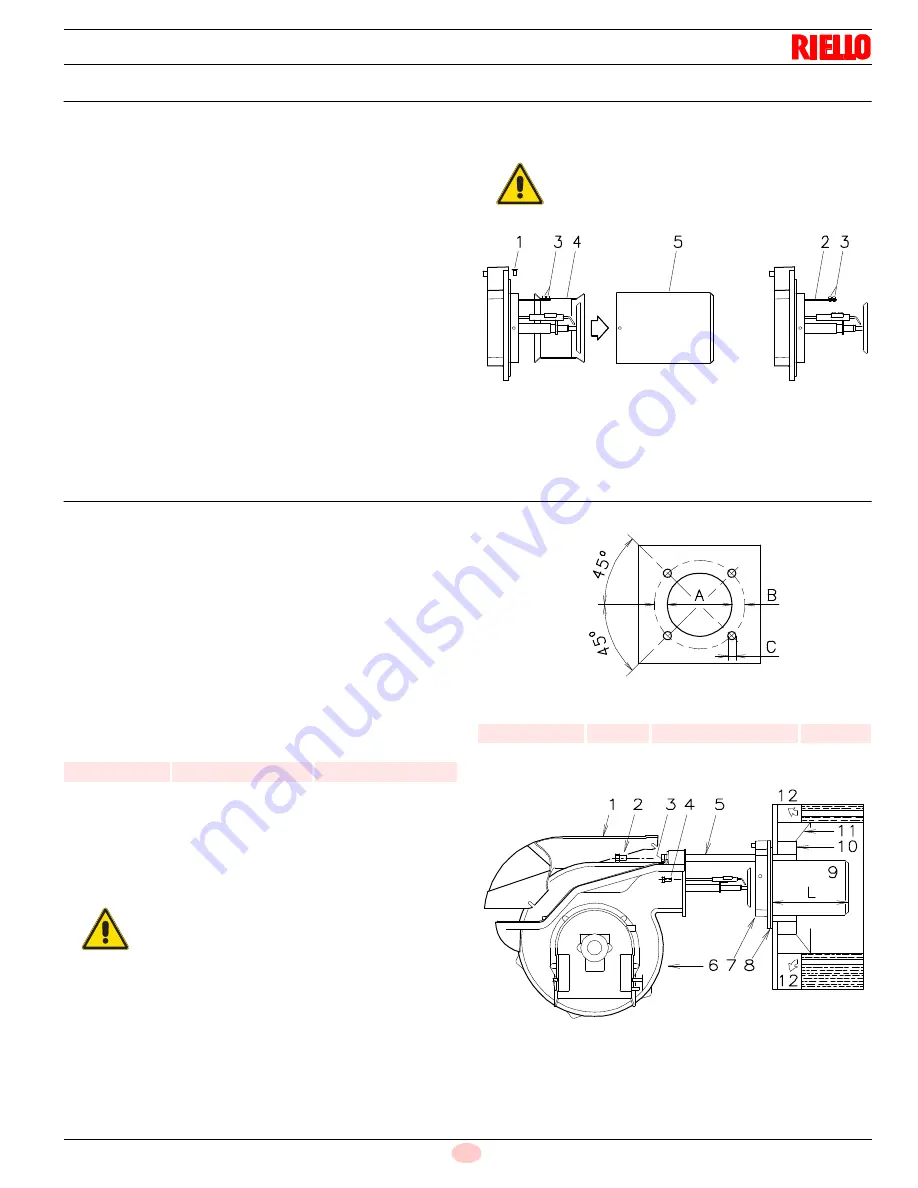

Once this operation has been carried out (if required), secure

flange 7)(Fig. 13) to the boiler plate inserting the supplied gasket

8)(Fig. 13).

Use the 4 screws provided after having protected the thread with

an anti-seize product.

4.6

Securing the burner to the boiler

4.6.1

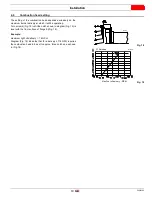

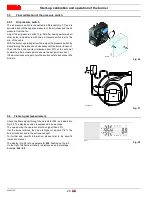

Boring the boiler plate

Drill the combustion chamber mounting plate as shown in Fig. 12.

The position of the threaded holes can be marked using the head

gasket supplied with the burner.

4.6.2

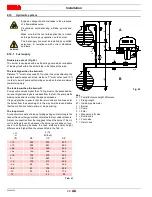

Length of the blast tube

The length of the blast tube must be selected according to the indi-

cations provided by the manufacturer of the boiler, and in any case

it must be greater than the thickness of the boiler door complete

with its refractory.

The available lengths “L” are those indicated in the Tab. F.

Tab. F

For boilers with front flue passes 12)(Fig. 13) or flame inversion

chambers, protective insulaton material 10) must be inserted be-

tween the boiler refractory 11) and the blast tube 9).

This protective insulation must not compromise the extraction of

the blast tube. See Fig. 13.

Tab. G

WARNING

The burner-boiler seal must be airtight.

Fig. 11

D690

Model

Short blast tube

Long blast tube

(with kit)

RL 70/E

7

9/32“

15

5/32“

WARNING

For boilers having a water-cooled front the insula-

tion 10)-11)(Fig. 13) is not required unless it is re-

quired by the boiler manufacturer.

inch

A

B

C

RL 70/E

7

9/32“

10

27/32“

- 12

13/16“

1/2 W

Fig. 12

D455

Fig. 13

D1219