Installation

21

20045163

GB

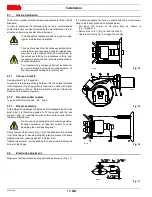

4.11

Hydraulic connections

The pumps are equipped with a by-pass that connects the return

line and suction line. The pumps are installed on the burner with the

by-pass closed by screw 6)(Fig. 22).

It is therefore necessary to connect both hoses to the pump.

The pump seal will be dammaged immediately if it is run with

the return line closed and the by-pass screw inserted.

Remove the plugs from the suction and return connections of the

pump.

Insert the hose connections with the supplied seals into the con-

nections and screw them down.

Take care that the hoses are not stretched or twisted during instal-

lation.

Install the hoses where they cannot be stepped on or come into

contact with hot surfaces of the boiler.

Now connect the other end of the hoses to the suction and return

lines.

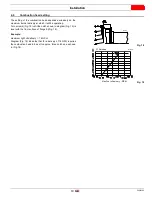

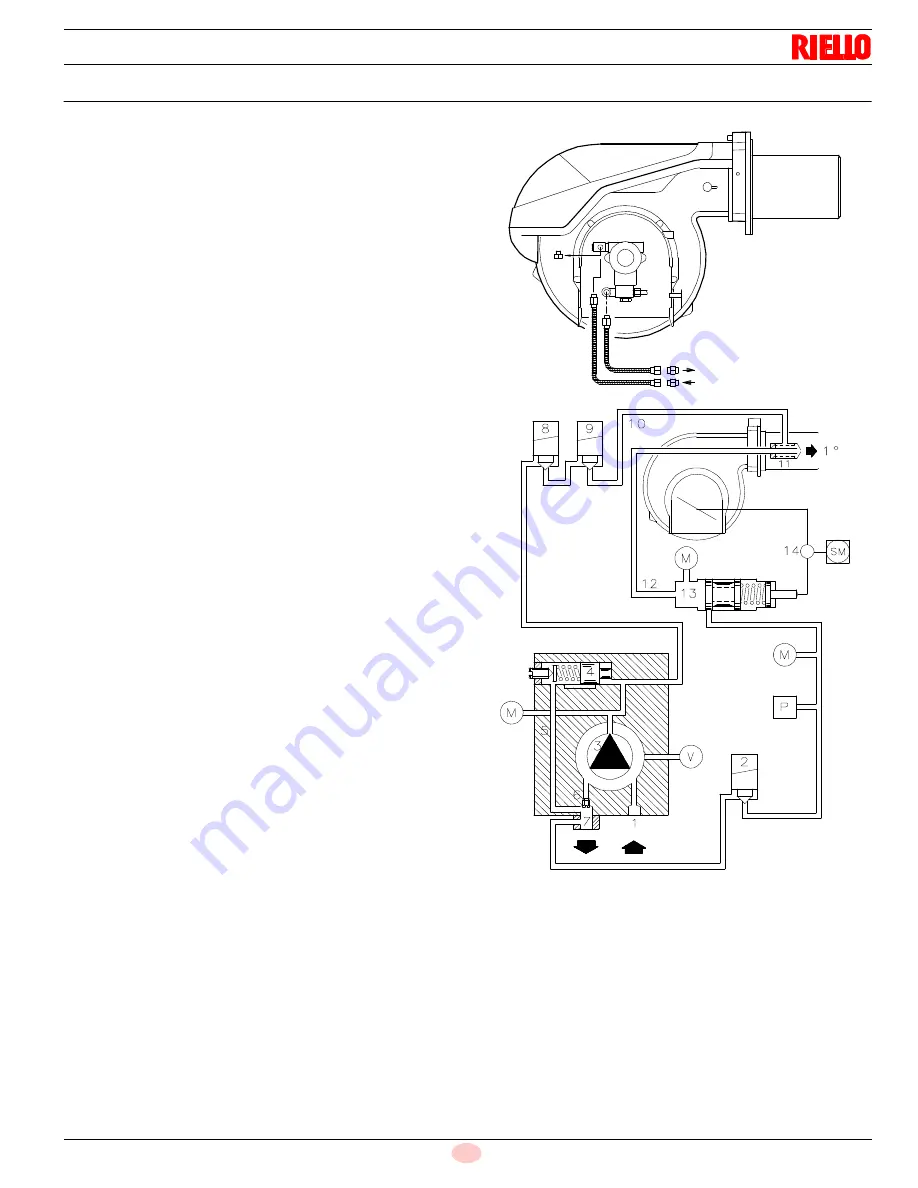

4.11.1

Oil hydraulic system layout

1

Pump suction

2

Solenoid valve

3

Pump

4

Pressure regulator

5

Return pipe

6

By-pas screw

7

Pump return

8

Solenoid valve

9

Solenoid valve

10

Piping

11

Filter

12

Piping

13

Pressure regulator

14

Servomotor

M

Pressure gauge

P

Oil pressure switch

V

Vacuum gauge

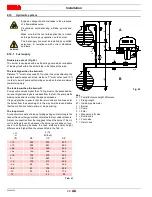

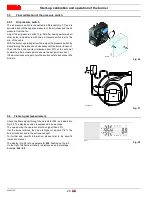

4.11.2

Oil pressure switch

The oil pressure switch 15)(Fig. 2, page 7) is factory set to 43.5 PSI

(3 bar).

If the oil pressure goes above this value in the return piping, the

pressure switch stops the burner.

Burner starts again automatically if the pressure goes down under

43.5 PSI (3 bar) after burner shut down.

If a loop circuit with Px pressure feeds the burner, the pressure

switch should be adjusted to Px + 43.5 PSI.

D1224

Fig. 21

D2444

Fig. 22