20168262

44

GB

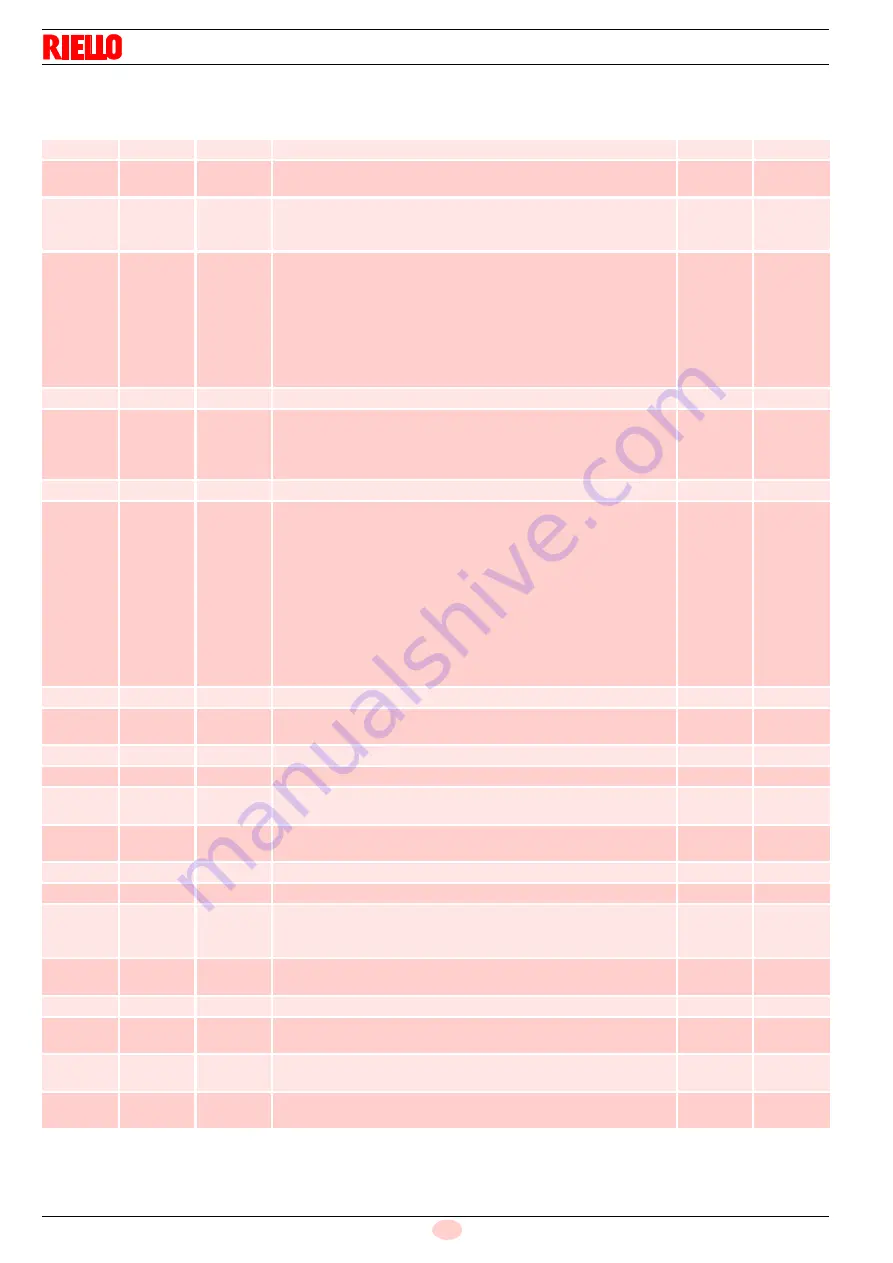

Faults - Possible causes - Solutions

803

0

0

The channel remains outside the 1

st

monitoring band for too long

Channel

804

0

0

The channel mode of the air/fuel ratio control does not correspond

to the type of activation

Channel

805

0

0

The direct control channel moves to an invalid position, i.e. a chan-

nel that is not deactivated or controlled by the air/fuel ratio control

C

set point

position

806

0

0

Channel set-point of the main controller not possible

C

set point

po

effective

value +

program-

ming toler-

ance

807

1

1

LSB message timeout (message no. = parameter)

Possible cause of the error:

–

connection between VSM/LCM GND and PE protective earth

–

speed modification confirmation too fast / VSM fault

–

LSB error (the red LED flashes or is constantly on)

889

0

0

The interval between two remote fault resets is too short

EN 14459 only allows 4 remote fault resets every 15 minutes.

The fault reset is monitored by remote control software, LAMTEC

SYSTEM BUS and a field bus. The overcoming of the fault reset

causes the H889 to stop and further remote fault resets are ignored.

After a delay time it is possible to carry out another fault reset.

The stopping of the H889 occurs when the fault reset is sent without

good reason. A reset from the terminal is always possible.

How to reset this fault:

–

wait 15 minutes and try again to reset the fault

–

cut off power to the BT300 for a moment, reconnect the power

supply and then reset the fault.

921

0

0

Relay actuator self-diagnostics: output fault at the oil valve

922

0

0

Relay actuator self-diagnostics: output fault at the ignition trans-

former

923

0

0

Relay actuator self-diagnostics: output fault at gas valve 1

924

0

0

Relay actuator self-diagnostics: output fault at gas valve 2

925

0

0

Relay actuator self-diagnostics: output fault at the ignition trans-

former

928

0

0

Relay actuator self-diagnostics: output fault at terminal 41 for oil

pump

929

0

0

Relay actuator self-diagnostics: output fault at impeller

985

0

0

VSM diagnostic error

Possible cause of the error:

BurnerTronic waiting for VSM module, but there is an error in the

exchange of diagnostic data with the module

986

0

0

The dynamic field test recognises invalid feedback

Channel

Effective

value

987

0

0

The change during operation in stages takes too long

988

0

0

The fuel selection relay in the DFM is defective or feedback is from

DFM is inconsistent

989

0

0

Plausibility test of the actuator feedback in programmed curve

failed

990

Optional

*1)

3

Power failure

Error

code

TRD

P301=0

P328>0

EN67

P301=2

P328>0

Description

D1

D2

Summary of Contents for RLS 120/E FGR

Page 2: ...Translation of the original instructions ...

Page 51: ...49 20168262 GB Appendix Electrical panel layout 01 2 3 4506 7 891 01 ...

Page 52: ...20168262 50 GB Appendix Electrical panel layout 0 1 2 2 2 0 ...

Page 54: ...20168262 52 GB Appendix Electrical panel layout 0 0 0 12 3456 7 12 3456 7 ...

Page 57: ...55 20168262 GB Appendix Electrical panel layout 0 0 1 2 3 4 5 667 8 667 2 9 63 8 63 63 3 5 ...