Maintenance

39

20096088

GB

Pump

Delivery pressure must correspond with the Fig. 17.

The depression must be less than 0.45 bar

.

Unusual noise must not be evident during pump operation

.

If the pressure is found to be unstable or if the pump runs noisily,

the flexible hose must be detached from the line filter and the fuel

must be sucked from a tank located near the burner. This measure

permits the cause of the anomaly to be traced to either the suction

line or the pump.

If the problem lies in the suction line, check to make sure that the

filter is clean and that air is not entering the piping.

Filters

Check the filtering baskets on line and at nozzle present in the sys-

tem. Clean or replace if necessary.

If rust or other impurities are observed inside the pump, use a sep-

arate pump to lift any water and other impurities that may have de-

posited on the bottom of the tank.

Nozzles

It is advisable to replace nozzles every year during regular main-

tenance operations.

Do not clean the nozzle openings; do not even open them.

Flexible hoses

Check to make sure that the flexible hoses are still in good condi-

tion.

Fuel tank

Approximately every 5 years, or whenever necessary, suck any

water or other impurities present on the bottom of the tank using a

separate pump.

Combustion

In case the combustion values found at the beginning of the inter-

vention do not respect the standards in force or, in any case, do not

correspond to a proper combustion, contact the Technical Assis-

tant and have him carry out the necessary adjustments.

Gas leaks

Make sure that there are no gas leaks on the pipework between the

gas meter and the burner.

Gas filter

Change the gas filter when it is dirty.

Combustion

In case the combustion values found at the beginning of the inter-

vention do not respect the standards in force or, in any case, do not

correspond to a proper combustion, contact the Technical Assis-

tant and have him carry out the necessary adjustments.

6.3

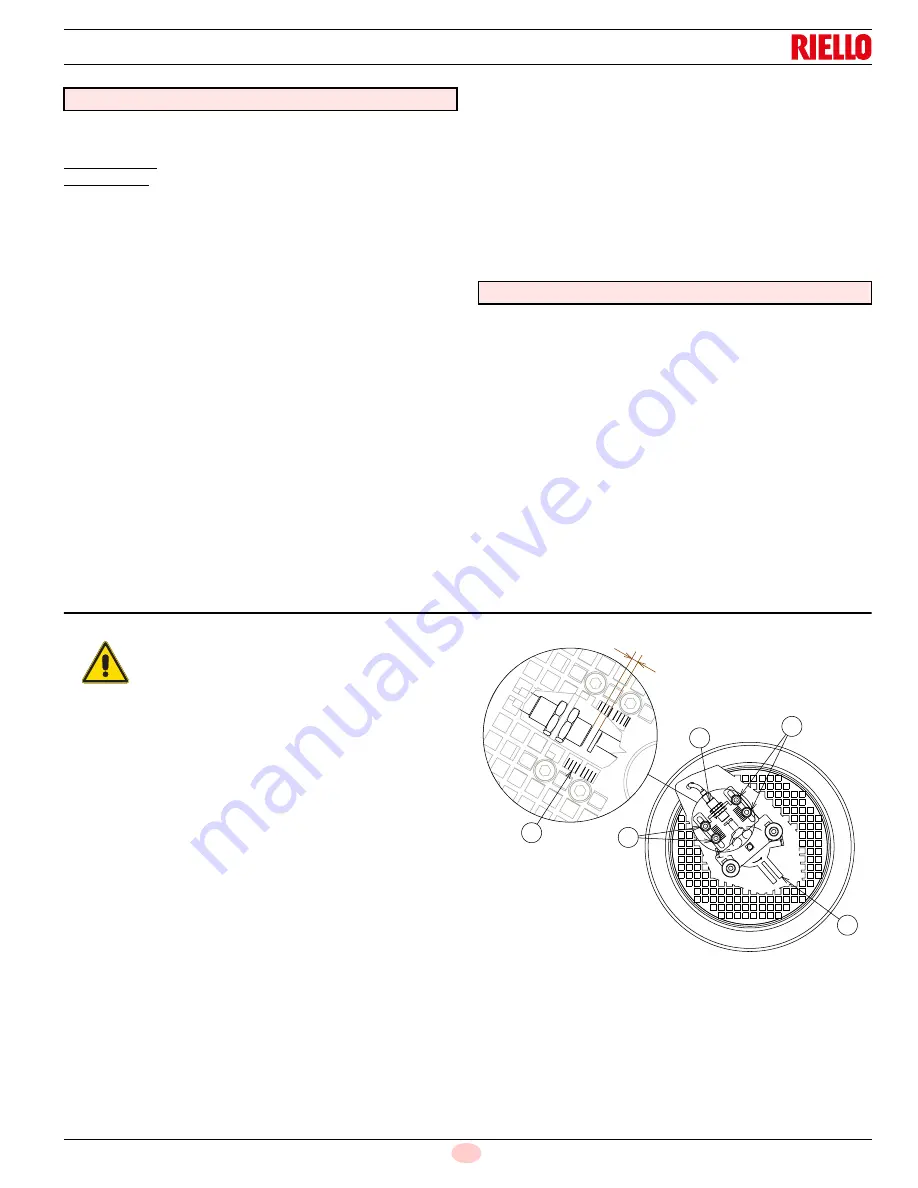

Checking the position of the speed sensor

To calibrate the speed sensor, proceed as follows:

loosen the screws 3) rest the sensor on the disc extension 2).

Take the scale 4) as a reference, pull back the speed sensor

by about a notch so that the distance from the disc extension

2) is about 2 mm = 5/64 inch.

Speed sensor

2

Disc

3

Screw

4

Scale

LIGHT OIL OPERATION

GAS OPERATION

WARNING

The measurement of speed sensor 1)(Fig. 53) must

be respected!

2

1

3

3

2

4

Fig. 53

20082216