19

20148049

GB

Installation

5.8

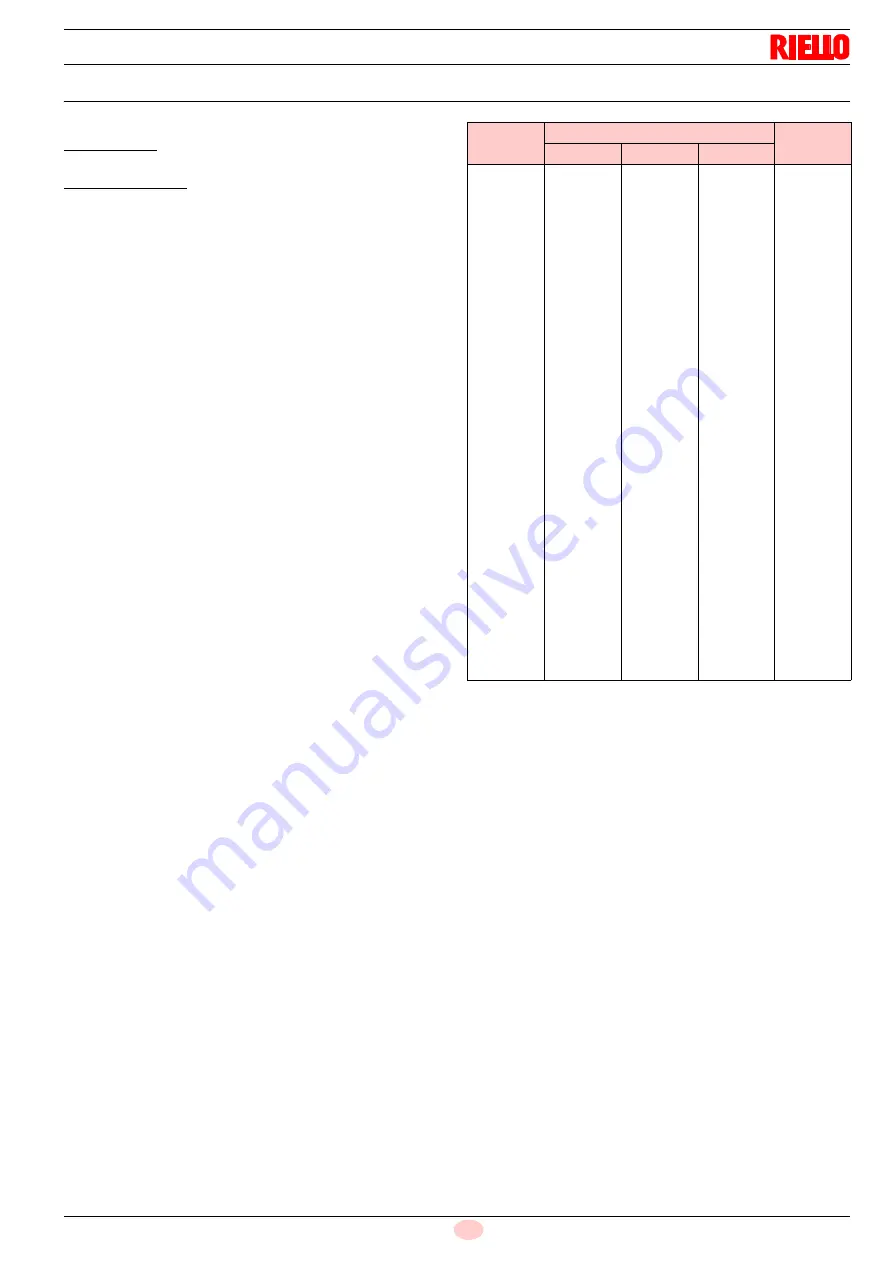

Choice of nozzles for the 1st and 2nd stage

Both nozzles must be chosen from among those listed in Tab. I.

The first nozzle determines the delivery of the burner at the 1st

stage.

The second nozzle works together with the 1st nozzle to

determine the delivery of the burner in the 2nd stage.

The outputs of the 1st and 2nd stage have to be within the value

range indicated in Tab. C on page 8.

Use nozzles with a 60° spray angle at the recommended

pressure of 12 bar.

Generally the two nozzles have the same flow rate but the nozzle

of the 1st stage can have an output that is 50% lower than the

total output, when you want to reduce the back pressure peak on

ignition (the burner provides good combustion values also with

40 - 100% ratios between the 1st and 2nd stage).

Example:

Boiler power = 1630 kW - efficiency 90 %

Burner requested output = 1630: 0.9 = 1812 kW;

1812: 2

= 906 kW per nozzle

so two equal nozzles of 60°, 12 bar are required:

1° = 18 GPH

2° = 18 GPH

or the following two different nozzles:

1° = 16 GPH

2° = 20 GPH

Tab. I

GPH

kg/h

kW

12 bar

10 bar

12 bar

14 bar

10.0

10.5

11.0

12.0

12.3

13.0

13.8

14.0

15.0

15.3

16.0

17.0

17.5

18.0

19.0

19.5

20.0

21.5

22.0

22.5

23.0

23.5

24.0

24.5

25.0

25.5

26.0

26.5

27.0

27.5

28.0

38.4

40.4

42.3

46.1

47.3

50.0

53.1

53.8

57.7

58.8

61.5

65.4

67.3

69.2

73.0

75.0

76.9

82.7

84.6

86.5

88.4

90.4

92.2

94.2

96.1

98.0

99.9

101.9

103.8

105.7

107.6

42.4

44.6

46.7

50.9

52.2

55.1

58.5

59.4

63.6

64.9

67.9

72.1

74.2

76.4

80.6

82.7

84.8

91.2

93.3

95.5

97.6

99.7

101.8

104.0

106.0

108.2

110.3

112.4

114.5

116.7

118.8

46.1

48.4

50.7

55.3

56.7

59.9

63.3

64.5

69.2

70.5

73.8

78.4

80.7

83.0

87.6

89.9

92.2

99.1

101.4

103.7

106.0

108.3

110.6

112.9

115.3

117.6

119.9

122.2

124.5

126.8

129.1

502.9

529.0

553.9

603.7

619.1

653.5

693.8

704.5

754.3

769.7

805.3

855.1

880.0

906.1

956.0

980.9

1005.8

1081.7

1106.6

1132.6

1157.5

1182.4

1207.3

1233.5

1257.2

1283.2

1308.2

1333.1

1358.0

1384.1

1409.0