20067636

32

GB

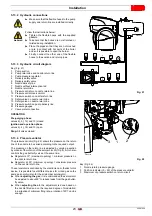

Start-up, calibration and operation of the burner

6.4

Adjustments prior to ignition (gas)

In addition, the following adjustments must also be made:

Slowly open the manual valves situated upstream from the

gas train.

Adjust the minimum gas pressure switch (Fig. 41) to the start

of the scale.

Adjust the maximum gas pressure switch (Fig. 40) to the end

of the scale.

Adjust the air pressure switch (Fig. 39) to the start of the

scale.

Purge the air from the gas line.

We recommend using a plastic tube routed outside the build-

ing and to purge air until gas is smelt.

Fit a U-type pressure gauge or a differential pressure gauge

(Fig. 38), with socket (+) on the gas pressure of the pipe

coupling and (-) in the combustion chamber.

The manometer readings are used to calculate MAX burner

output.

Connect two lamps or testers to the two gas line solenoids to

check the exact moment in which voltage is supplied.

This operation is unnecessary if each of the two solenoid

valves is equipped with a pilot light that signals voltage pass-

ing through.

6.5

Burner start-up (gas)

Close the remote controls and position the selector 1)(Fig. 37) to

“

AUTO

”.

Position the selector 2) to “

GAS

” to select gas as fuel.

Make sure that the lights or testers connected to the solenoids, or

the pilot lights on the solenoids themselves, indicate that no volt-

age is present. If voltage is present, stop the burner immediately

and check the electrical connections.

When the limit thermostat (TL) closes, the “

CALL FOR HEAT

” 3)

signal must come on. The burner will subsequently begin its start-

ing cycle.

6.6

Burner ignition

The burner should light after having performed the above steps.

If the motor starts up, but the flame does not appear and the con-

trol box goes into lockout, reset it and wait for a new ignition at-

tempt.

If ignition is still not achieved, it may be that gas is not reaching

the combustion head within the safety time period of 3 seconds;

In this case increase gas ignition delivery.

The arrival of gas at the sleeve is indicated by the U-type manom-

eter (Fig. 38).

If further burner lockouts occur, refer to the “Release procedure”

given in the equipment manual supplied.

Once the burner has fired, now proceed with global calibration

operations.

6.7

Change of fuel

There are three options of change of fuel:

1

with the AZL device 4)(Fig. 37);

2

with selector 2);

3

with a remote selector connected to the main terminal

board.

Positioning the selector 2)(Fig. 37) to “EXT” activates the remote

selection of the fuel. In this position, if there is no remote selector,

the AZL device defines the priority fuel and the selected fuel is

shown on the display.

CAUTION

Before starting up the burner, it is good practice to

adjust the gas train so that ignition takes place in

conditions of maximum safety, i.e. with gas deliv-

ery at the minimum.

Fig. 38

20124126

Summary of Contents for RLS 1600/EV C11

Page 2: ...Original instructions ...

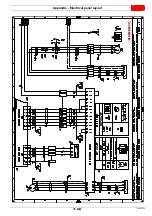

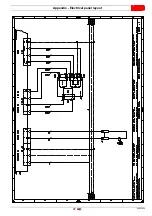

Page 48: ...20067636 46 GB Appendix Electrical panel layout 0 0 0 0 0 0 0 0 ...

Page 49: ...47 20067636 GB Appendix Electrical panel layout ...

Page 51: ...49 20067636 GB Appendix Electrical panel layout ...

Page 52: ...20067636 50 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 53: ...51 20067636 GB Appendix Electrical panel layout 0 1 0 ...

Page 54: ...20067636 52 GB Appendix Electrical panel layout 0 1 1 1 2 1 3 1 1 1 1 1 1 1 41 4 4 1 1 2 1 ...

Page 55: ...53 20067636 GB Appendix Electrical panel layout 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 4 ...

Page 56: ...20067636 54 GB Appendix Electrical panel layout 0 0 1 2 0 0 3 3 3 0 1 4 ...

Page 62: ......

Page 63: ......