33

20067636

GB

Start-up, calibration and operation of the burner

6.8

Combustion air adjustment

Fuel/combustion air synchronisation is done with the relevant

servomotors (air and gas) by logging a calibration curve by

means of the electronic cam.

It is advisable, to reduce the loss and for a wide calibration field,

to adjust the servomotors to the maximum of the output used, the

nearest possible to the maximum opening (90°).

On the gas butterfly valve, fuel step according to the burner out-

put required, with servomotor completely open, is carried out by

the pressure stabiliser placed on the gas train.

The values indicated in Tab. J and Tab. K can be a reference for

a good combustion calibration.

Tab. J

Tab. K

6.8.1

Air / gas adjustment and output modulation

The air/gas adjustment and output modulation system with which

the

RLS

range burners are equipped carries out a series of inte-

grated functions in order to optimise burner functioning, both for

single operation and together with other units (e.g. double fur-

nace boiler or more than one generator in parallel).

The basic system functions control:

1

The dosage of the air and fuel through positioning using

direct servo commands of the relevant valves eliminating

the possible play in the calibration systems with mechanical

cam lever mechanisms, used on traditional modulating

burners.

2

The modulation of the burner output in accordance with the

load required by the system, with maintenance of the pres-

sure or temperature of the boiler at the operating values set.

3

The sequence (cascade adjustment) of more than one

boiler through the suitable connection of the various units

and the activation of the internal software of the individual

systems (option).

Further interfaces and communication functions with computers,

for remote control or integration in central supervision systems

are available on the basis of the configuration of the system.

The first start-up and curve synchronisation manual is supplied

with the burner.

At request, the complete manual for the control and setting of all

parameters is available.

EN 676

Air excess

CO

Max. output

1.2

Max. output

1.3

GAS

Theoretical max

CO

2

0 % O

2

CO

2

% Calibration

mg/kWh

= 1.2

= 1.3

G 20

11.7

9.7

9

1000

G 25

11.5

9.5

8.8

1000

G 30

14.0

11.6

10.7

1000

G 31

13.7

11.4

10.5

1000

EN 267

Air excess

CO

Max. output

1.2

Min. output

1.3

Theoretical max CO

2

0 % O

2

CO

2

% Calibration

mg/kWh

= 1.2

= 1.3

15.2

12.6

11.5

1000

WARNING

The first start up and every further internal setting

operation of the adjustment system or the expan-

sion of the base functions require access by

means of password and are to be carried out by

service personnel who are especially trained for

the internal programming of the instrument and

the specific application created with this burner.

Summary of Contents for RLS 1600/EV C11

Page 2: ...Original instructions ...

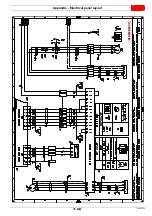

Page 48: ...20067636 46 GB Appendix Electrical panel layout 0 0 0 0 0 0 0 0 ...

Page 49: ...47 20067636 GB Appendix Electrical panel layout ...

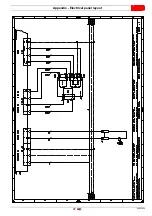

Page 51: ...49 20067636 GB Appendix Electrical panel layout ...

Page 52: ...20067636 50 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 53: ...51 20067636 GB Appendix Electrical panel layout 0 1 0 ...

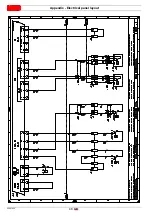

Page 54: ...20067636 52 GB Appendix Electrical panel layout 0 1 1 1 2 1 3 1 1 1 1 1 1 1 41 4 4 1 1 2 1 ...

Page 55: ...53 20067636 GB Appendix Electrical panel layout 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 4 ...

Page 56: ...20067636 54 GB Appendix Electrical panel layout 0 0 1 2 0 0 3 3 3 0 1 4 ...

Page 62: ......

Page 63: ......