33

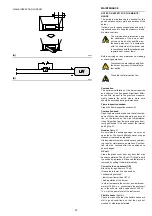

ELECTRICAL CONNECTIONS (A)

Use flexible cables according to EN 60 335-1

regulations.

All the wires to connect to the burner must enter

through the supplied fairleads.

The fairleads and hole press-outs can be used

in various ways; the following lists show one

possible solution:

1 - M25 - Three-phase powersupply

2 - M20 - Single-phase power supply

3 - M20 - Triggering / Safety devices

4 - Available

Cable grommets used in the factory:

A - Fan motor

B - Servomotor

C - Pump motor

D - Safety solenoid

E - 1

st

stage solenoid valve

F - 2

nd

stage solenoid valve

G - Maximum gas pressure switch

H - Flame sensor

The burner has been type- approved for inter-

mittent operation. This means it shoulds com-

pulsorily be stopped at least once every 24

hours to enable the control box to perform

checks of its own efficiency at start-up. Burner

halts are normally provided for automatically by

the boiler load control system.

If this is not the case, a time switch should be fit-

ted in series to IN to provide for burner shut-

down at least once every 24 hours.

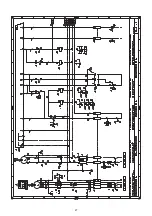

Wiring must be performed by qualified

personnel in accordance with the

regulations in force in the country of

destination.

Riello S.p.a. declines all responsibility for

changes or wiring performed in any way

other than that illustrated in these diagrams.

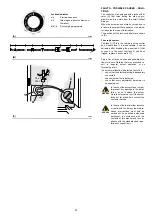

CALIBRATION OF THE THERMAL RELAY (B)

The thermal relay is used to avoid damage to

the motor owing to a strong increase in absorp-

tion or the lack of a phase.

For the calibration

2)

, refer to the table given in

electrical layout (Electrical connections set by

installer).

To reset, in the case of an intervention of the

thermal relay, press the button “RESET”

1)

.

The button “STOP”

3)

opens the NC (95-96)

contact and stops the motor.

To test the thermal relay, insert a screwdriver in

the window “TEST/TRIP”

4)

and move it in the

sense of the arrow (towards right).

Do not invert the neutral with the

phase wire in the electricity sup-

ply line.

Automatic resetting can be dan-

gerous. This action is not pro-

vided for the burner operation.

B

G

4

A

D C

E F

H

4

1

2

4

3

3

4

(A)

D8880

1

2

3

MAN

AUT

O

STOP

NO

98

97

96

95

RESET

NC

4

TEST/TRIP

(B)

D8685

WARNING

WARNING

Summary of Contents for RLS 250/M MZ

Page 2: ...Original instructions 说明书原文翻译 ...

Page 29: ...27 0 0 0 0 1 2 33 0 3 1 45 45 67 67 8 2 9 0 0 3 2 ...

Page 30: ...28 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 ...

Page 32: ...30 0 1 1 2 2 0 3 4 5 6 3 0 2 7 5 6 4 8 0 5 5 9 4 9 4 1 2 1 ...

Page 36: ......

Page 62: ...26 0 0 0 0 1 2 33 0 3 1 45 45 67 67 8 2 9 0 0 3 2 ...

Page 63: ...27 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 ...

Page 65: ...29 0 1 1 2 2 0 3 4 5 6 3 0 2 7 5 6 4 8 0 5 5 9 4 9 4 1 2 1 ...

Page 69: ......

Page 70: ......

Page 71: ......